Tube - Fabric - 0.500 x 1.000 x 72 Inch [BUILT TO ORDER]

P/N

46643

Product Details:

Built To Order ◾ Lead times are usually 2 weeks ◾ High quantities may have an increased lead time

- 1 $549.99

- 2-4 $411.79

- 5-9 $324.59

- 10+ $254.39

Features & Benefits

Fabric roll wrapped tubing offers many benefits over uni-directional and even filament wound tubing. That isn't to say it is the best however. Here are a few reasons you may wish to consider fabric roll wrapped tubing for your application.

- Superior machine ability

- Much better durability by reducing the potential extent of fiber breakout if drilled, machined or damaged

- Typical aesthetic associated with carbon fiber products

- Most "fabric" tubes contain a majority 0° plies in the layup allowing for the most effective bending load support. (whereas filament wound tubes cannot achieve angles less than ~7°

Additional Information

| P/N | 46643 |

|---|---|

| Built To Order | Yes |

| Space Flight Ready | No |

| Traceability Included | No |

| Inside Dimension | 0.500000 |

| Outside Dimension | 1.000000 |

| OD | 1.000000 |

| Wall | 0.250000 |

| Length | 72 |

| Tensile Modulus (Stiffness), msi | 12.710000 |

| Max Operating Temp (Tg) | 238.000000 |

| WT. | 2.410000 |

| Materials | Standard Modulus Carbon |

| HTS - Harmonized Tariff Code | 6815.13.0000 |

| Surface Finish (exterior) | Cello Wrap Gloss |

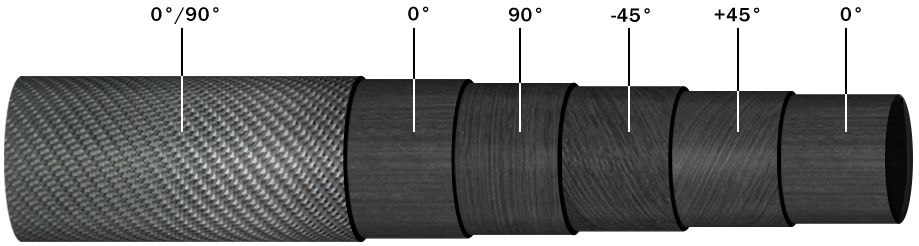

Layup Orientation

|

SKU : 46643 Rev NC |

||

| Ply # | Orientation | Location |

| 1 | 0 | Inside |

| 2 | 0 | ↓ |

| 3 | 0 | |

| 4 | 0 | |

| 5 | 90 | |

| 6 | 90 | |

| 7 | 90 | |

| 8 | 0 | |

| 9 | 0 | |

| 10 | 0 | |

| 11 | 45 | |

| 12 | 45 | |

| 13 | -45 | |

| 14 | -45 | |

| 15 | 0 | |

| 16 | 0 | |

| 17 | 0 | |

| 18 | 0 | |

| 19 | 90 | |

| 20 | 90 | |

| 21 | 90 | |

| 22 | 90 | |

| 23 | 0 | |

| 24 | 0 | |

| 25 | 0 | |

| 26 | 0 | |

| 27 | -45 | |

| 28 | -45 | |

| 29 | 45 | |

| 30 | 45 | |

| 31 | 0 | |

| 32 | 0 | |

| 33 | 0 | |

| 34 | 90 | |

| 35 | 90 | |

| 36 | 90 | |

| 37 | 0 | |

| 38 | 0 | |

| 39 | 0 | |

| 40 | 0 | |

| 41 | 0/90 | Outside |

- 0° Fibers maximize bending stiffness. Consider bending the tube over your knee.

- 45° Fibers maximize torsional stiffness. Typically plied together in an opposing manner, i.e. ±45°. Consider twisting the tube like a vehicle's driveshaft.

- 90° Fibers maximize crushing stiffness and generally assist in overall tube strength. Consider laying the tube on the ground and stepping on it.

Request A Quote