What does filament count mean?

Filament count is the number of individual filaments that are included in each tow.

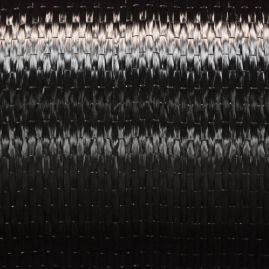

TOW:

Tow is the strand or small bundle of carbon that you see in woven fabric or spools of carbon fiber.

FILAMENT:

Filaments are the individual carbon fibers included in the tow or strand.

FILAMENT COUNT (1k, 3k 6k, 12k, etc.):

This number indicates the total number of filaments included in a tow. The “k” represents 1000. For instance, a 3k filament count is 3000 individual filaments contained in a single tow or strand.

MEANING OF FILAMENT COUNT:

The higher the filament count, the thicker and more difficult the material is to handle with bends and compound curves. Filament count choice should be determined by the engineering requirements.

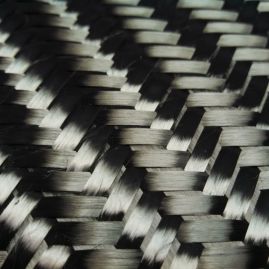

Advantages of unidirectional fabric

Unidirectional fabrics have all the fibers running in a single direction. These materials have certain advantages over woven fabrics.

PLY ORIENTATION:

The technician has greater control over exact ply orientation for stiffer and lighter components.

LAMINATE THICKNESS:

Unidirectional fibers are thinner than woven fabrics, so you have more control over laminate thickness.

RESIN CONTENT:

Resin content is kept to a more controlled amount due to flatter laminates, which have less void space than woven fabrics.

Disadvantages of unidirectional fabric

THIN PLIES:

It can take longer to laminate a part because the plies are typically 50% thinner than woven.

FRAYED EDGES:

Edges are more susceptible to fraying and delaminating the length of the fiber.

DRAPABILITY:

Unidirectional fibers are hard to laminate on tight inside and outside corners. The fibers are very stiff and don’t naturally bend.

COSMETICS:

Unidirectional layups do not present the same as woven and don’t have a typical carbon fiber look.

Advantages of woven fabric

DRAPABILITY:

Some weaves will conform to compound curves better because of loose weaves and weave patterns. They also maintain adjacent fiber angles while conforming to complex shapes. (Unidirectional fibers are very difficult to conform to sharp inside and outside corner.) 2x2 twill is the most common for good drapability.

COSMETIC:

Some patterns just look better from a distance and are used to get that traditional carbon fiber look. Again, 2x2 twill is very common.

DURABILITY:

Woven fabrics resist edge fraying better than unidirectional fibers, especially when damaged. The woven tows will stop fraying as they pass under the perpendicular adjacent fibers. Some designers will place a single ply on the outside surface for durability and cosmetics.

THICKNESS BUILDUP:

Woven fabrics are thicker than unidirectional fibers, so they build thickness faster than unidirectional layups.

ISOTROPIC SIMPLICITY:

With each ply, you have an automatic isotropic layup with equal stiffness in two directions. (Isotropic: having a physical property which has the same value when measured in different directions.)

Disadvantages of woven fabric

PLY ORIENTATION:

With woven fabrics, there is always equal number of fibers running in one direction as is running in the perpendicular direction. This limits the customizable ply orientation by always including ply orientations in two directions for every ply.

FIBER CRIMPING:

As the fiber is woven, it passes over and under perpendicular fibers creating a slight bend in the fiber. As carbon fiber is strongest when it is straight, this crimping can cause a slight loss in bending stiffness. This is generally thought of as minimal, but in some structural applications, it can be a very important distinction.

RESIN CONTENT:

Woven fabrics will require a little more resin content to fill in all the gaps between the woven tows. Typically, it is about 5-10% more resin for woven fabrics. This can add weight and change the structural aspects of the part.

What are typical weave patters?

There are quite a few different weave patterns. Here are the most common.

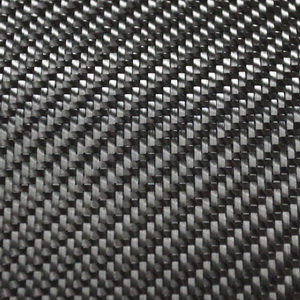

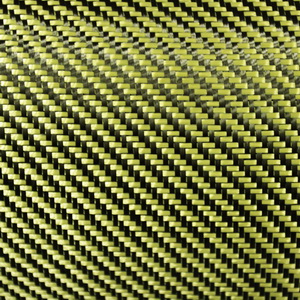

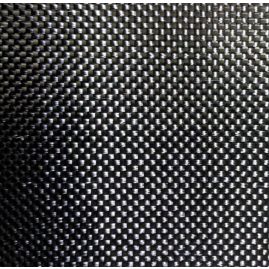

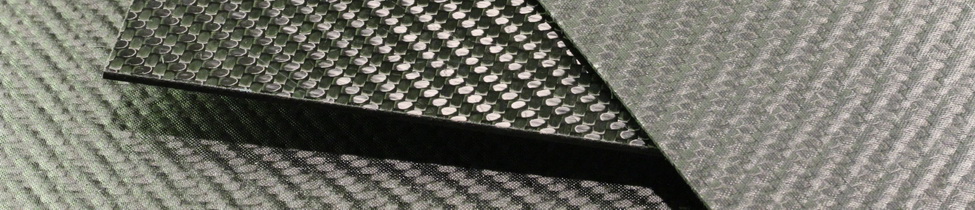

PLAIN WEAVE:

Each strand is woven over one perpendicular strand, then under the next, then the pattern repeats.

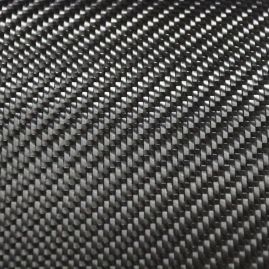

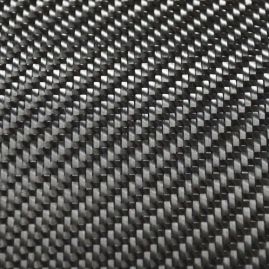

2X2 TWILL:

A twill weave is 2 strands over two strands and then under two strands. However, the adjacent strands are staggered by one strand to create a diagonal affect.

SPREAD TOW CHECKERBOARD:

These patterns or typically a plain weave pattern but use a single tow that is spread extra wide to create a very broad tow. This has specific benefits:

- Reduces the total crimping of the weave to increase the structural aspect of the fabric.

- Reduces ply thickness to help control total part thickness.

- Reduces resin content.

- Mimics a 0° and 90° unidirectional layup with a single ply.

- Offers excellent cosmetics.

Dry Woven Fabric - Tri-Weave - Carbon, Kevlar, Glass - 50 Inch WideSKU: 13050-GROUP

Dry Woven Fabric - Tri-Weave - Carbon, Kevlar, Glass - 50 Inch WideSKU: 13050-GROUP Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - ~10,000 lbs, 10 Palleted Gaylords (Shipped Freight)SKU: 13051-D-10000LBS$124,499.99SKU: 13051-D-10000LBS

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - ~10,000 lbs, 10 Palleted Gaylords (Shipped Freight)SKU: 13051-D-10000LBS$124,499.99SKU: 13051-D-10000LBS Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - ~1,000 lbs, 1 Palleted Gaylord (Shipped Freight)SKU: 13051-D-1000LBS$16,649.99SKU: 13051-D-1000LBS

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - ~1,000 lbs, 1 Palleted Gaylord (Shipped Freight)SKU: 13051-D-1000LBS$16,649.99SKU: 13051-D-1000LBS Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Large Bucket - 13 lbsSKU: 13051-D-L$320.99SKU: 13051-D-L

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Large Bucket - 13 lbsSKU: 13051-D-L$320.99SKU: 13051-D-L Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Medium Bucket - 6.0 lbsSKU: 13051-D-M$173.99SKU: 13051-D-M

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Medium Bucket - 6.0 lbsSKU: 13051-D-M$173.99SKU: 13051-D-M Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Small Bucket - 2.5 lbsSKU: 13051-D-S$92.99SKU: 13051-D-S

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Small Bucket - 2.5 lbsSKU: 13051-D-S$92.99SKU: 13051-D-S Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Extra Small Bucket - 1.5 lbsSKU: 13051-D-XS$68.99SKU: 13051-D-XS

Chopped Carbon Fiber - Epoxy Compatible Sizing - 12mm Length Fiber - Extra Small Bucket - 1.5 lbsSKU: 13051-D-XS$68.99SKU: 13051-D-XS