Frequently Asked Questions

Here you will find commonly asked questions related to our order process, our off-the-shelf products, technical attributes, and our custom quoting process.

If you have questions about composites, whether technical or general, please refer to the sections below.

The Order Process

Below are common questions regarding the order process.

Orders

Do you have a catalog?

To be as eco-friendly as possible we do not offer a printed catalog. All of our available products, pricing structures, and ordering can be done

online.

I am in Utah. Can I come visit the facility or pick up my order?

For ecommerce orders, yes. When ordering locally, please place the order online prior to coming in. The order must be placed online before Noon MST for the order to be ready same day and available for pick up at 4pm or later. You are welcome to stop by our Salt Lake City location anytime during our business hours to view our facility and see our products in person. Our business hours are 8am – 5pm Monday through Thursday. 8am to 3:30pm on Fridays. If you are a school wanting a tour, please email us at info@rockwestcomposites.com.

Visits to our San Diego location must be coordinated with your Business Development representative

Do you sell to the public?

Yes. Our pricing structures are the same for both business and individual customers.

As a business can I get a discount?

Our pricing structure is based strictly on product quantity. These low prices are available to individuals and businesses equally. RWC prices and discounts are subject to change without notice and do not include any state or local taxes. Buyer shall pay, in addition to the price of the goods, all applicable taxes and excises unless Buyer furnishes RWC with a valid “Reseller Number” or copy of tax exemption certificates prior to ordering. Refund for sales tax cannot be refunded after order has been placed. Prices are quoted and payable in US Dollars. All orders are subject to applicable shipping, freight, taxes, and handling charges

Is there a minimum order?

Not for most items. However we do have required lengths. Most of our tubing is sold as full length tubes (72”) and sometimes smaller sizes (sizes will be listed in the length field). The filament wound tubes are sold per foot.

Can I make an order online if I am an international customer?

Yes. Our online ordering system allows for international shipments. These are subject to additional charges due to importation and customs fees. Rock West will not be responsible for reimbursement of these fees unless Rock West shipped erroneously. On occasion the charges automatically collected by the website may not be sufficient for the service, and we will reach out to you to collect the difference.

Payment

What forms of payment do you accept?

A major credit card or bank debit card is required to prepay all purchases. We accept MasterCard, Visa, and American Express.

Credit terms: All orders are subject to credit approval. Unless otherwise agreed to in advance, terms are NET 30 DAYS FROM DATE OF INVOICE. Rock West Composites (RWC) may require full or partial payment, or a payment guarantee, in advance of shipment whenever, in its opinion, the financial condition of the Buyer warrants such a requirement. RWC reserves the right to assess a service charge of 1.5% per month on outstanding balances until they are paid. Buyer shall be liable for all expenses, including attorney's fees, related to the collection of past due accounts. RWC reserves the right to withhold shipment of materials pending resolutions of past due account balances and the right to revise credit terms based on credit history.

Do you charge sales tax?

In response to the Wayfair Decision, we charge tax in states where we do not qualify for an exemption and are required to do so by law. Currently, those states include California, Colorado, Georgia, Illinois, Indiana, Maryland, Michigan, Minnesota, New Jersey, North Carolina, Pennsylvania, Rhode Island, South Carolina, Utah, Washington, and Wisconsin. This list changes regularly.

If you would like to submit an exemption, you must create an account on the website and submit your Sales Tax Resale Certificate to us via the email taxes@rockwestcomposites.com. The exemption must be approved before purchasing, as we cannot issue refunds for tax after the sale has been completed. Please reference the email address associated with your account when submitting your forms. The approval process usually takes 1-2 business days. (See Tax Exemptions under Payment Terms on our Policies page).

How can I determine if I will be charged tax, so I know to submit my Sales Tax Resale Certificate?

Fill your cart with your desired order and then view the cart. Under Estimate Shipping, enter your destination/postal code and shipping method. Scroll down to the Cart Summary, and you will see your estimated price, including tax if applicable. If you determine that you need to submit your certificate to avoid sales tax, you can log in and save your cart for later. Please submit your certificate as instructed in the previous response (or refer to 'Tax Exemptions' under 'Payment Terms' on our Policies page). Once approved for exemption, you can log in, load your saved cart, and make your purchase.

Cancellations

What is your cancellation policy?

Orders may be cancelled without cancellation charges, provided RWC has not initiated the order. Cancellations made within 24 hours of placement, if the item has not been shipped, are generally accepted and incur no fee. Cancellations made after this time will be subject to review. If manufacturing work has already begun, any cancellation will be treated as a return and will be subject to our return policy. Therefore, cancellations of non-returnable items will not be accepted, and all accepted cancellations will incur a 25% restocking fee. See the Return section for more information.

Shipping

What shipping methods do you offer?

Most orders are shipped by United Parcel Service (UPS) Ground. If the product is available, expedited shipping options, such as 3 Day Select, 2nd Day Air, and Next Day Air, will be provided for orders shipping within the US. If you have a UPS/ FedEx account, we can ship "collect" on your account.

How much is US shipping?

Shipping costs are determined by the following factors: weight, length, and exact zip code. You can expect to pay anywhere from $15 to $30 for UPS Ground shipping, depending on the factors above.

Oversize/Overweight Shipping

An additional cost will apply to packages 95” or longer. Anything 105” or longer will require crate packaging and is available only for ground shipping. Packages that are 100 lbs or more will also incur additional cost.

Is there a cost for using shipping accounts?

A 5% handling fee will be added to the total of your order if you use your UPS/FedEx shipping account. This covers the cost of packaging and handling orders.

How long will it take for my order to be processed and shipped once it is placed?

Here is a UPS Ground chart.

Most orders placed will be processed the following day. This applies to Next Day Air and any other expedited services. If you need an order shipped the same day, please call us before 12:00 pm MST to determine if we can fulfill your request, as the product may not be in stock. We may be temporarily out of stock on an item, in which case we will, in good faith, keep you updated and give an expected lead time for production.

All goods are sold FOB (Free on Board) RWC shipping point. Goods may be shipped in a single shipment or multiple shipments at RWC's discretion. RWC will attempt, in good faith, to meet the estimated shipping dates but shall not be liable to the Buyer for any loss or damages due to delays caused by RWC. We cannot guarantee that all products are available and ready to ship. We do our best to maintain sufficient inventory on hand to fulfill anticipated orders, although occasionally a large order will arrive that depletes specific items. If you have any questions, please email orderstatus@rockwestcomposites.com to check our inventory status.

Do you ship internationally?

Yes. Our international order policy is as follows: We ship exclusively through UPS. Shipping rates will vary depending on the location. International shipments are subject to additional charges due to importation and customs fees. Rock West will not be responsible for reimbursement of these fees unless Rock West shipped erroneously. Please email us at orderstatus@rockwestcomposites.com if you have any questions.

Location

Does Rock West Composite have a distributor in my area?

Our products are currently only offered directly from our Utah facility.

Do you manufacture your products?

Rock West Composites manufactures the majority of the products you see on our website at our facilities in Salt Lake City, Utah & Tijuana, Mexico. We also distribute a range of products, including adhesives, fabrics, and prepregs, sourced from other suppliers.

Composite Products

Below are answers to frequently asked questions on our composite products. These are focused on the most common questions our team is asked regarding composites, recommendations, and instructions. Continue to the section below this for information on Technical Specifications.

UV Resistance

Are RWC Composite Tubes UV-Resistant?

No. The resin systems used in composite materials are rarely suited for prolonged UV exposure. To achieve UV resistance, we recommend sanding the tubing smooth and then having an automotive shop paint the tubes to your liking. If your need is for more than 10 tubes, we will be happy to provide pricing for us to do it for you.

Forming Tubes

Can I Form Carbon Fiber Tubing/Plate By Heating It?

No. The carbon we offer is made using a thermoset resin chemistry, which provides greater stiffness and strength properties. If you want something that can be heat-formed, you must look for a thermoplastic-based resin system. This is not common in our industry (yet).

Cutting Carbon Fiber

General Guidelines

Always wear safety glasses & a respirator when cutting composite materials, as fine dust is often generated during the process.

High (spindle) speed, low (travel per time) feed. This is a good rule of thumb when cutting composites with traditional tooling (e.g., drilling, milling, etc.)

What Do You Use To Cut Carbon Fiber?

FOR TUBING:

We use high-speed wet saws with diamond abrasive round saw blades.

You can also use a tile saw, abrasive metal-cutting wheels, or a Dremel with a diamond-cutting wheel.

Do not use a hack saw.

FOR PLATES AND SANDWICH PANELS:

We use a waterjet or CNC mill with carbide tools or diamond abrasive tools. Alternatively, we can make straight cuts on panel saws using a diamond-coated saw blade, dry cut with vacuum evacuation, or use a large tile saw with a wet diamond abrasive saw.

You can use a tile saw, abrasive metal-cutting wheels, or a Dremel with a diamond-cutting wheel.

Do not use a hack saw.

FOR HOLES:

We use carbide drill bits.

You could use any metal drill bits or carbide drill bits.

Do not use concrete bits.

TIP: When cutting, if you are getting chunks, increase the tool's speed and slow down the amount you are cutting at a time. Seeing just dust is good!

FOR DRY MATERIALS (FABRICS AND PREPREGS):

For most materials we sell, we sell them in their raw form (before cure and/or resin infusion), and sharp scissors work very well. Electric shears will make short work of cutting dry materials. For aramids (e.g., Kevlar), we recommend using finely serrated scissors.

Fabric Uses (Clothing, Masks)

Can RWC Dry Fabrics Be Used In Face Coverings?

No. Our dry fabrics are intended for industrial use, not for textile applications.

Carbon Fiber Stiffness

Which Is The Stiffer Carbon Fiber Tube: Unidirectional Tubing, Fabric Tubing, Or Filament Wound Tubing?

Unidirectional and Fabric tubing will be slightly stiffer (in bending) than the Filament Wound tubing. Each of these processes inherently produces different tube stiffnesses due to different fiber wrap angles (or layup). Filament wound tubing is generally better suited for torsional (twist) applications, while Unidirectional and Fabric tubing are generally better suited for bending.

How Much Stiffer Is A Carbon Fiber Tube Than An Aluminum Tube?

Carbon fiber is typically 1.4-1.5 times stiffer than aluminum, all other factors being equal.

Carbon Fiber vs Aluminum

How Much Lighter Is A Carbon Fiber Tube Than An Aluminum Tube?

Carbon fiber is 2/3 the weight of aluminum (or 1/3 less).

How Much Stiffer Is A Carbon Fiber Tube Than An Aluminum Tube?

Carbon fiber is typically 1.4-1.5 times stiffer than aluminum, all other factors being equal.

Tube Finishes: Sanded Vs. Unsanded

What's The Difference Between Sanded and. Unsanded "Cello Wrap (Gloss)" Tube Finishes?

The primary difference between these two finish options lies in surface smoothness and visual appearance.

UNSANDED CELLO WRAP (GLOSS):

This is offered as our standard finish. The texture of the tube can be described as "ribbed" and features a dark, glossy black finish.

Pros: Hard/tough surface, excellent for general abuse, looks good too.

Cons: Outer diameter tolerance is not as easily controlled.

Twill Fabric – Unsanded Cello Wrap (Gloss)

Uni – Unsanded Cello Wrap (Gloss)

Filament Wound – Unsanded Cello Wrap (Gloss)

SANDED:

Provides a smooth surface finish and a matte gray visual.

Pros: Sanding enables us to dial in an outer diameter; however, this may distort the pattern on the fabric tubing if a specific OD is requested.

Cons: Sanding removes the "protective" outer layer of cured resin, exposing the raw fiber. This, however, provides a paint-ready surface, allowing you to apply any UV-resistant or clear gloss paint coat.

Twill Fabric – Sanded smooth matte

Uni – Sanded smooth matte | Bicycle Tubing

Filament Wound – Sanded smooth matte

Stock Product Finishes

What About Other Finishes On Stock Products?

Filament Count (3k, 12k, etc.)

What Does Filament Count Mean?

Filament count is the number of individual filaments that are included in each tow.

TOW:

Tow is the strand or small bundle of carbon that you see in woven fabric or spools of carbon fiber.

FILAMENT:

Filaments are the individual carbon fibers that make up the tow or strand.

FILAMENT COUNT (1K, 3K, 6K, 12K, ETC.):

This number indicates the total number of filaments included in a tow. The "k" represents 1000. For instance, a 3k filament count is 3000 individual filaments contained in a single tow or strand.

MEANING OF FILAMENT COUNT:

The higher the filament count, the thicker and more difficult the material is to handle with bends and compound curves. The engineering requirements should determine filament count choice.

Unidirectional Fabrics

Advantages Of Unidirectional Fabric.

Unidirectional fabrics have all the fibers running in a single direction. These materials have certain advantages over woven fabrics.

PLY ORIENTATION:

The technician has greater control over exact ply orientation for stiffer and lighter components.

LAMINATE THICKNESS:

Unidirectional fibers are thinner than woven fabrics, allowing for greater control over laminate thickness.

RESIN CONTENT:

Resin content is kept to a more controlled amount due to flatter laminates, which have less void space than woven fabrics.

Disadvantages Of Unidirectional Fabric.

THIN PLIES:

It can take longer to laminate a part because the plies are typically 50% thinner than those of woven material.

FRAYED EDGES:

Edges are more susceptible to fraying and delaminating the length of the fiber.

DRAPABILITY:

Unidirectional fibers are hard to laminate on tight inside and outside corners. The fibers are very stiff and don't naturally bend.

COSMETICS:

Unidirectional layups do not present the same as woven and don't have a typical carbon fiber look.

Woven Fabrics

Advantages Of Woven Fabric.

DRAPABILITY:

Some weaves will conform to compound curves better due to their loose weaves and specific weave patterns. They also maintain adjacent fiber angles while conforming to complex shapes. (Unidirectional fibers are tough to conform to sharp inside and outside corners.) 2×2 twill is the most common for good drapability.

COSMETIC:

Some patterns appear more visually appealing from a distance and are used to achieve the traditional carbon fiber look. Again, 2×2 twill is very common.

DURABILITY:

Woven fabrics resist edge fraying better than unidirectional fibers, especially when damaged. The woven tows will stop fraying as they pass under the perpendicular adjacent fibers. Some designers will place a single ply on the outside surface for durability and cosmetics.

THICKNESS BUILDUP:

Woven fabrics are thicker than unidirectional fibers, so they build thickness faster than unidirectional layups.

ISOTROPIC SIMPLICITY:

With each ply, you have an automatic isotropic layup, resulting in equal stiffness in both directions. (Isotropic: having a physical property that has the same value when measured in different directions.)

Disadvantages Of Woven Fabric.

PLY ORIENTATION:

With woven fabrics, there is always an equal number of fibers running in one direction as are running in the perpendicular direction. This limits the customizable ply orientation by always including ply orientations in two directions for every ply.

FIBER CRIMPING:

As the fiber is woven, it passes over and under perpendicular fibers, creating a slight bend in the fiber. As carbon fiber is strongest when it is straight, this crimping can cause a slight loss in bending stiffness. This is generally considered minimal, but in some structural applications, it can be a crucial distinction.

RESIN CONTENT:

Woven fabrics will require a bit more resin content to fill in all the gaps between the woven tows. Typically, it is about 5-10% more resin for woven fabrics. This can add weight and change the structural aspects of the part.

Typical Weave Patterns

What Are Typical Weave Patterns?

There are several different weave patterns. Here are the most common.

PLAIN WEAVE:

Each strand is woven over one perpendicular strand, then under the next; the pattern repeats.

2X2 TWILL:

A twill weave consists of two strands over two strands, followed by two strands under two strands. However, the adjacent strands are staggered by one strand to create a diagonal effect.

SPREAD TOW CHECKERBOARD:

These patterns are typically a plain weave pattern, but use a single tow that is spread extra wide to create a very broad tow. This has specific benefits:

- Reduces the total crimping of the weave to increase the structural aspect of the fabric.

- Reduces ply thickness to help control total part thickness.

- Reduces resin content.

- Mimics a 0° and 90° unidirectional layup with a single ply.

- Offers excellent cosmetics.

Technical Specifications

Below is a repository of technical specifications, tolerances, and guides for all of our products and materials. For more specific technical information, please visit the individual product page.

Tube Tolerances

General Stock Tube Tolerances

For round and shaped composite tubing, including ID, OD, and length:

Adhesives

Adhesives Specifications.

Shear strength, cure time, work life, etc.

INFINITube Telescoping Systems

INFINITube Guides

Choose the proper clamp/tube combination:

Plate Tolerances

Carbon Fiber Plates

Information on dimensional tolerances, materials, and resins:

- Stock Plates – Panels – Angles Tolerance Sheet Rev. NC

- Unidirectional finish – Uni Plate Specs

- Fabric 40x-xx part #’s

- T-700 Carbon Fiber – 670 GSM Carbon Fiber Fabric

- Rhino FG 1411 Epoxy Resin, with Rhino FG 4111 Epoxy Hardener Rhino – 1411/4111 TDS

Carbon Fiber Specifications

Prepreg

Standard fibers used in our manufacturing processes:

Common fibers used in our manufacturing processes:

- Standard Modulus – 35msi – TR50S Fiber

- Standard Modulus – 33msi – T700S

- Intermediate Modulus – 42msi – MR60 Fiber

- High Modulus – 57msi – HR40 Fiber

Filament Winding

Common fibers used in our manufacturing processes:

- Standard Modulus – 34msi (or higher, up to 37msi, and 800ksi) – 34-700 24K Tow / Fiber

- Intermediate Modulus – 42msi – MR60 Tow / Fiber

- High Modulus – 57msi – HR40 Tow / Fiber

- High Modulus – 66msi – HS40 Tow / Fiber

Resin Infusion

Common fibers used in our manufacturing processes:

- Standard Modulus – 33msi – T700S

Resin Systems Specifications

Prepreg Resin Systems

Standard resin systems, the majority of 250F systems, used in our manufacturing processes include the following:

Filament Winding Resin Systems

Bisphenol F liquid epoxy resin (Epon 862 is our commonly used resin; however, we may swap this at our discretion) / Hardener (Lindride 6K)

West Systems Resins & Hardeners

Safety Data Sheets

Safety Data Sheets.

Additional safety data sheets may be available upon request or on product-specific pages:

- Carbon Fiber – Toray Fiber (used in most SM prepregs)

- Carbon Fiber – Dry Woven Fiber

- Kevlar – Braided Fiber

- Kevlar – Dry Woven Fiber

- Fiberglass – Filament / Fiber

- Prepreg Resin- Newport 301

Custom Quote Process

We receive questions about custom work quite often on our website. You may have an idea for a new product, but you're unsure how or if it can be manufactured using carbon fiber. You have no idea what it will cost to do so, and you wonder how the cost may change as you transition from prototype to mass production. Well, here are some answers for you!

CAD Models

Do You Have A CAD Model?

Please provide a detailed computer-aided design (CAD) model of your idea. This will help us determine the best way to manufacture it (depending on the complexity). If all you have is a sketch, that's okay, but eventually we'll need to involve one of our designers to model it on the computer to work out the missing details. This exercise may cost anywhere from $500 to several thousand dollars, depending on its complexity. However, we don't necessarily need this work performed to provide you with a cost estimate for prototyping your idea.

Special Requirements

What Special Requirements Need To Be Considered?

Is your part expected to carry "loads"? Will it support the weight of another structure or have something else pushing or pulling on it while it's in use? Then we'll need to help you determine the composite design (ply layup) and wall thicknesses. We have engineers who can help with this! If it's a quick exercise, we'll do it for free during the quoting process. If it's complicated and involved, we'll include this cost in the quote.

Manufacturing Methods

What Manufacturing Method Will Be Used?

To estimate the cost of your prototype, we'll need to determine the manufacturing method and whether any tooling (such as mandrels or molds) is required to produce your part. If it's a simple part, such as a tube, the chances are that we'll have a mandrel in-house, which will save you some money. If we don't have the mandrel, then buying one for your project may cost $500-1500, depending on the material and the size (diameter) of the mandrel.

Tooling for Complex Shapes

What Tooling Is Needed For Other Shapes?

If your part is more complex in shape, we'll likely need to create a mold. The cost of a mold can vary greatly depending on the size and complexity (say, from $3000 – $50,000!). If you have a relatively small part, such as a ski pole handle with basic features, the chances are that the mold will cost somewhere in the $ 3,000 – $8,000 range.

Determining Cost Estimate

How Do We Determine The Cost Estimate?

Once we have the part and mold designed, the layup determined, and the process identified, we'll be able to decide on how long it will take to manufacture the part and what the cost will be. This will be determined by calculating the amount of "touch labor" required and whether any additional operations, such as cutting, trimming, or sanding, are necessary. We will come back to you with the total cost to produce your prototype, including design, materials, labor, and tooling, so that you can make an informed decision about whether to proceed.

Volume Discounts

Are There Volume Discounts?

At this point in the process, we'll also provide you with a reasonably accurate estimate of the cost of the part in larger volumes. It will undoubtedly be less expensive in higher quantities because some parts of the process may be more automated and because we will have worked out some of the kinks while prototyping. The higher volume cost varies from project to project, but you can expect a price reduction of 10-25% when producing hundreds of parts compared to just one.

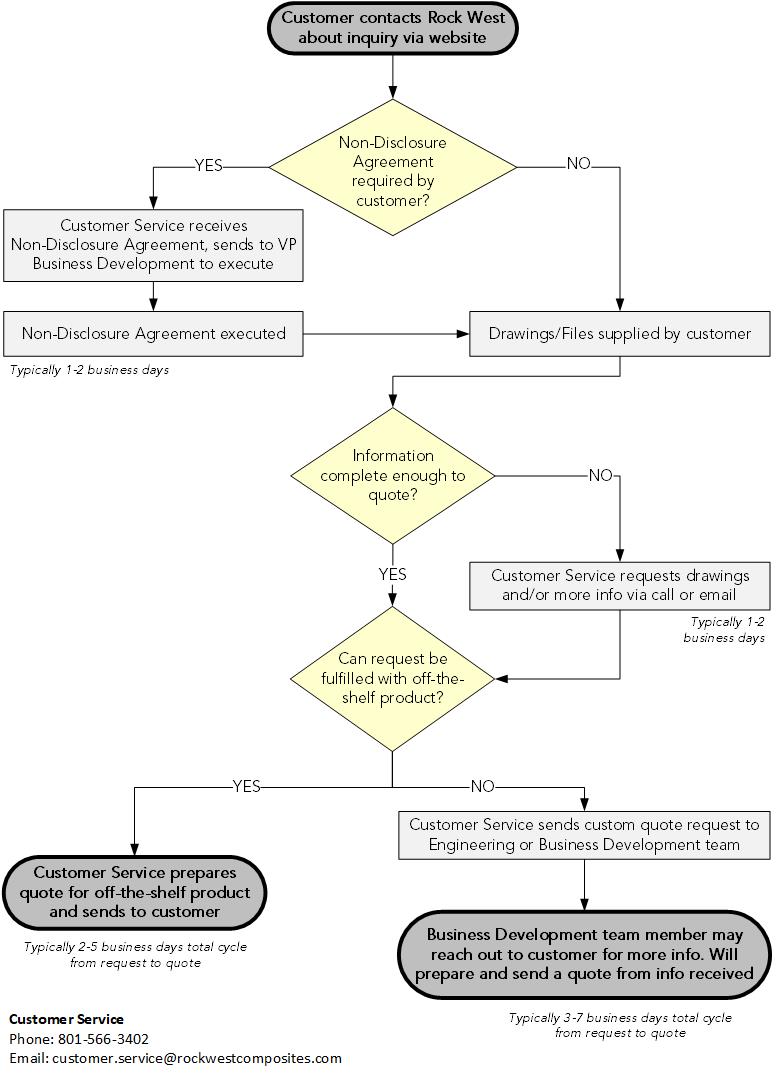

Custom Quote Process

How Long Does It Take To Get A Quote?

The timeframe for a custom quote will vary depending on the original information provided, whether an NDA is required, and other factors. This flow chart explains our process.