Tube - Unidirectional - 5.0 x 5.13 x 60 Inch [BUILT TO ORDER]

Built To Order ◾ Lead times are usually 2 weeks ◾ High quantities may have an increased lead time

- 1 $799.99

- 2-4 $632.79

- 5-9 $536.59

- 10+ $447.39

Features & Benefits

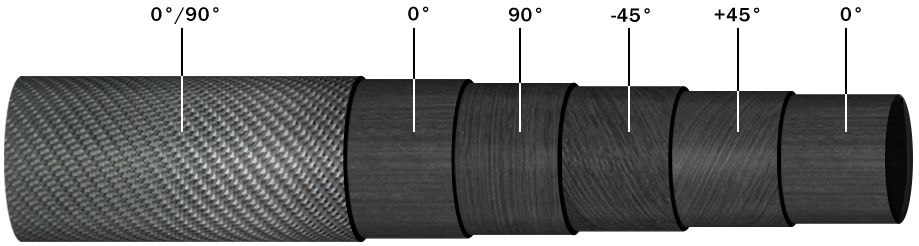

Roll wrapped tubing is manufactured using multiple layers of prepreg carbon fiber (and if noted, other) materials. In general each layer is about 0.006 inches thick which means that a tube with a wall thickness of 0.060 inches will typically be composed of 9-10 individual layers of carbon fiber. The number of layers (plys) allows us to vary the orientation of the fibers throughout the thickness, creating a high performance, engineered product. Click HERE to learn more about our roll wrapping process.

*Please note, the diagram below shows an outer "0/90" ply however the product you are currently viewing does NOT have this outer twill ply.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup please check out the "LAYUP ORIENTATION" tab.

Additional Information

| P/N | 45672 |

|---|---|

| Built To Order | Yes |

| Space Flight Ready | No |

| Traceability Included | No |

| Inside Dimension | 5.000000 |

| Outside Dimension | 5.130000 |

| OD | 5.130000 |

| Wall | 0.064000 |

| Length | 60 |

| Tensile Modulus (Stiffness), msi | 13.570000 |

| Max Operating Temp (Tg) | 238.000000 |

| WT. | 3.430000 |

| Materials | Standard Modulus Carbon |

| HTS - Harmonized Tariff Code | 6815.13.0000 |

| Surface Finish (exterior) | Cello Wrap Gloss |

Technical Data

|

SKU: 45672 Rev A |

||

| Ftu-Lengthwise | 125 | ksi |

| Tension Strength | 129.7 | k-lb |

| Fcu-Lengthwise | 76 | ksi |

| Compression Strength | 79.2 | k-lb |

| Flexure Strength | 76 | ksi |

| Internal Pressure | 340 | psi |

| Tension Modulus | 12.1 | Msi |

| Compression Modulus | 11.8 | Msi |

Layup Orientation

|

SKU : 45672 Rev A |

||

| Ply # | Orientation | Location |

| 1 | 0 | Inside |

| 2 | 0 | ↓ |

| 3 | 90 | |

| 4 | 90 | |

| 5 | 0 | |

| 6 | 0 | |

| 7 | 90 | |

| 8 | 90 | |

| 9 | 0 | |

| 10 | 0 | |

| 11 | 0 | Outside |

- 0° Fibers maximize bending stiffness. Consider bending the tube over your knee.

- 45° Fibers maximize torsional stiffness. Typically plied together in an opposing manner, i.e. ±45°. Consider twisting the tube like a vehicle's driveshaft.

- 90° Fibers maximize crushing stiffness and generally assist in overall tube strength. Consider laying the tube on the ground and stepping on it.