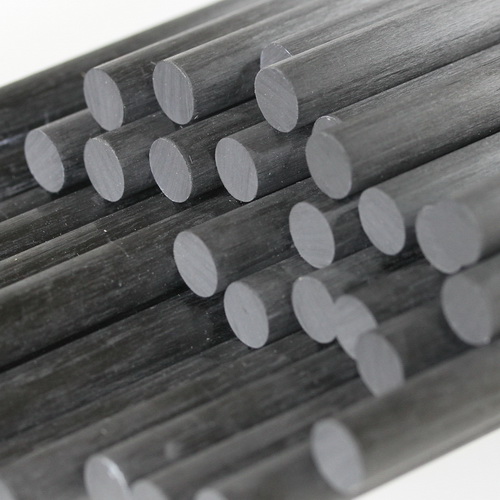

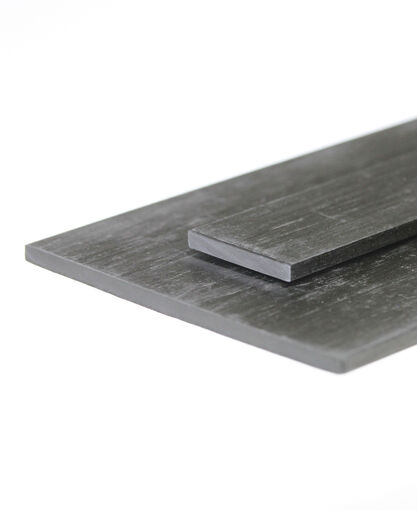

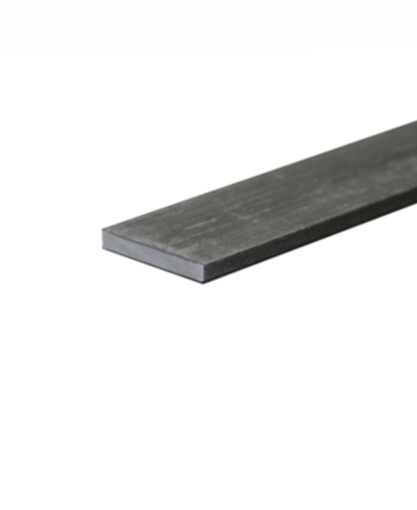

Rods

We carry tons of composite rods in a wide variety of shapes and sizes. From carbon fiber to fiberglass, we strive to have most of what you need available to ship out the next business day. We're also able to cut rods to a variety of lengths. We offer custom composite rods if you aren't able to find what you need off-the-shelf.

View:

103 item(s)

Sort By:

Price

.JPG?sw=417&sh=510)