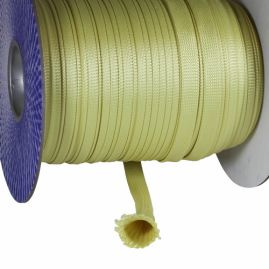

Braided Socks

Fiber orientation optimized for torsional stiffness◾Kevlar sock has fantastic impact toughness

There are many applications for braided sock. For example, dry Kevlar sock is often slid over tubular compression battens to add impact toughness and keep the batten pieces together in the event a batten breaks. Carbon sock can be slid over an existing tube or structure and wet out with one of our resin systems to dramatically increases the strength of the tube. Braided sleeves easily and repeatably conform to the geometry of the part they are slid over. Sleeves can expand by as much as 20-25% of their original nominal diameter

P/N

Pattern

Materials

Inside Dimension

Outside Dimension

Wall

Price