Tube - Aero Streamline - 1.985 Major Axis x 0.832 Minor Axis x 0.030 Wall x 40 Inch

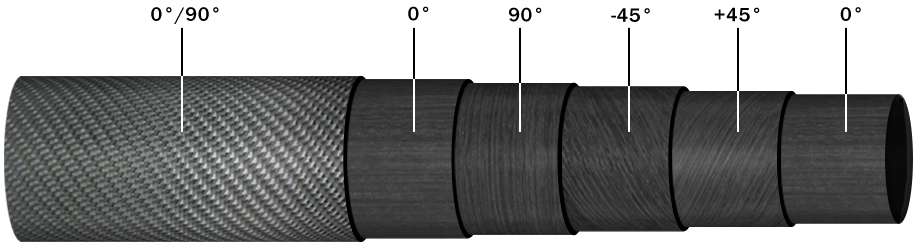

Unlike metals, which have similar properties in all directions (isotropic), the properties of composites vary, dependent on the orientation of the fibers in each layer.

- Fabric Tubing has an outer ply of woven material (denoted below as 0°/90°). Typically, this outer ply is a 2x2 twill weave (diagonal appearance seen below), but it can also be a plain weave (small checkerboard), spread tow (large format plain weave/checkerboard), or other off-axis weave such as a braid. The core of these tubes is almost always comprised of multi-directional "uni" plies.

- Uni Tubing is comprised of multi-directional "uni" plies just like the fabric tubes; however, instead of the outer ply being fabric, it is unidirectional and most typically oriented at 0° (fibers running the length).

- To learn about our Roll Wrapping Process click here.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup, please check out the "LAYUP ORIENTATION" tab.

Additional Information

| Application | General Purpose |

|---|---|

| Shape | Aero / Streamline |

| Materials | Standard Modulus Carbon |

| Pattern | 3k 2X2 Twill Weave |

| Color | Black |

| Finish | Satin |

| Inside Diameter | 1.985 |

| Outside Diameter | 2.045 |

| Major ID | 1.985 |

| Major OD | 2.045 |

| Minor ID | 0.8328 |

| Minor OD | 0.8928 |

| Length | 40 |

| Length (max continuous) | 40.0 |

| Linear Density | 0.094 |

| Volumetric Density | 0.055 |

| Weight | 0.312 |

| Primary Fiber | Tenax UTS50 |

| Primary Resin / Hardener | Eporite EHM32 |

Engineering Properties

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

| Avg EX Young's Modulus | 9300000.0 |

|---|---|

| Avg EY Young's Modulus | 9300000.0 |

| GXY Shear Modulus | 600000.0 |

| X Tensile Yield Strength | 103000.0 |

| X Compressive Yield Strength | 89000.0 |

| Y Tensile Yield Strength | 103000.0 |

| Y Compressive Yield Strength | 89000.0 |

| XY Shear Strength | 10618.0 |

| CTEX | 2.00E-06 |

| CTEY | 2.00E-06 |

| Poisson's Ratio vXY | 0.035 |

| Poisson's Ratio vYX | 0.035 |

- "X" is along the length of a tube, rod, plate, or panel.

- "Y" is around the perimeter of a tube, perpendicular to the length of pultruded parts, or along the width of a plate or panel.

Calculators

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

Layup Orientation

25653 Rev B

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | All 0/90 | Inside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.