Tube - Unidirectional - NEG ZTE - 3.000 x 3.163 x 82 Inch

ZTE CARBONTM High Modulus tubes are specifically designed for extremely low CTE. Our precision processing and high stiffness materials makes them a good choice as affordable tubes for dimensionally stable structures such as optical benches, precision robotics and other similar structures.

Our tubes are specifically engineered to have essentially no residual distortion (hysterisis) in elongation, bend or twist after exposure to high or low temperatures in applications where such properties are required.

Features & Benefits

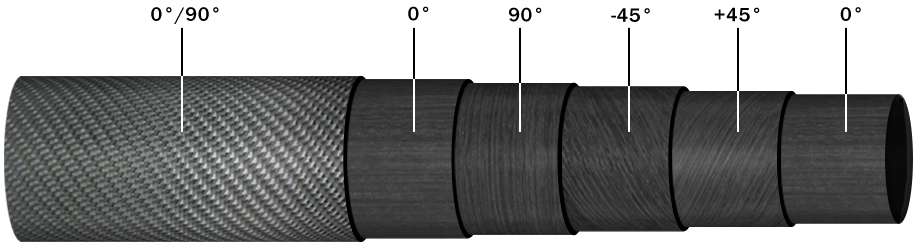

Roll wrapped tubing is manufactured using multiple layers of prepreg carbon fiber (and if noted, other) materials. In general each layer is about 0.006 inches thick which means that a tube with a wall thickness of 0.060 inches will typically be composed of 9-10 individual layers of carbon fiber. The number of layers (plys) allows us to vary the orientation of the fibers throughout the thickness, creating a high performance, engineered product.

*Please note, the diagram below shows an outer "0/90" ply however the product you are currently viewing does NOT have this outer twill ply.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup please check out the "LAYUP ORIENTATION" tab.

Additional Information

| Application | Low CTE |

|---|---|

| Shape | Round |

| Materials | High Modulus Carbon |

| Pattern | Unidirectional |

| Color | Black |

| Finish | Cello Wrap Gloss |

| Inside Diameter | 3.0 |

| Outside Diameter | 3.163 |

| Wall Thickness | 0.082 |

| Length | 82 |

| Length (max continuous) | 82.0 |

| Linear Density | 0.54 |

| Volumetric Density | 0.057 |

| Weight | 3.688 |

| Primary Fiber | Pyrofil HR40 |

| Primary Resin / Hardener | Newport 321 |

| Temperature Rating (F) | 300.0 |

| Max Operating Temp- (Tg) | 300F to 349F |

| Space Flight Ready | true |

| HTS - Harmonized Tariff Code | 6815.13.0000 |

Engineering Properties

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

| Avg EX Young's Modulus | 2.179E7 |

|---|---|

| Avg EY Young's Modulus | 6477000.0 |

| GXY Shear Modulus | 3739000.0 |

| X Tensile Yield Strength | 132800.0 |

| X Compressive Yield Strength | 120700.0 |

| Y Tensile Yield Strength | 47810.0 |

| Y Compressive Yield Strength | 37910.0 |

| XY Shear Strength | 30980.0 |

| CTEX | -2.15E-08 |

| CTEY | 3.09E-06 |

| Poisson's Ratio vXY | 0.39 |

| Poisson's Ratio vYX | 0.116 |

- "X" is along the length of a tube, rod, plate, or panel.

- "Y" is around the perimeter of a tube, perpendicular to the length of pultruded parts, or along the width of a plate or panel.

Calculators

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

Layup Orientation

45695-ZTE-R82 Rev A

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | 0 | Inside |

| 2 | 0 | ↓ |

| 3 | 0 | |

| 4 | 45 | |

| 5 | -45 | |

| 6 | 0 | |

| 7 | 0 | |

| 8 | 45 | |

| 9 | -45 | |

| 10 | 0 | |

| 11 | 0 | |

| 12 | 90 | |

| 13 | 90 | |

| 14 | 0 | |

| 15 | 0 | |

| 16 | -45 | |

| 17 | 45 | |

| 18 | 0 | |

| 19 | 0 | |

| 20 | -45 | |

| 21 | 45 | |

| 22 | 0 | |

| 23 | 0 | |

| 24 | 0 | Outside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.

Technical Data

We offer two tube products to choose from: -P engineered to have a slightly positive CTE, and -N engineered to have a slightly negative CTE.

| Typical Values | -P | -N |

| Elongation (ppm/°F) | 0.04 | -0.05 |

| Twist (Arcsec/ft./°F) | ±0.10 | ±0.15 |

| Bend (Arcsec/ft./°F) | ±0.08 | ±0.08 |

| Modulus (MSI) | 21 | 21 |

*Note: CTE values listed here are on average 20x lower than typical carbon fiber laminates!

Available on request

- CTE Testing

- Custom Sizes

ZTE Tubing Data Sheet

Layup Orientation

45695-ZTE-R82 Rev A

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | 0 | Inside |

| 2 | 0 | ↓ |

| 3 | 0 | |

| 4 | 45 | |

| 5 | -45 | |

| 6 | 0 | |

| 7 | 0 | |

| 8 | 45 | |

| 9 | -45 | |

| 10 | 0 | |

| 11 | 0 | |

| 12 | 90 | |

| 13 | 90 | |

| 14 | 0 | |

| 15 | 0 | |

| 16 | -45 | |

| 17 | 45 | |

| 18 | 0 | |

| 19 | 0 | |

| 20 | -45 | |

| 21 | 45 | |

| 22 | 0 | |

| 23 | 0 | |

| 24 | 0 | Outside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.