Tube - Tapered OD - Standard Modulus - 2x2 Twill Weave - 1.188 X 1.260 to 1.392 X 83.5 IN

Unlike metals which have similar properties in all directions (isotropic), the properties of composites are varying, dependent on the orientation of the fibers in each layer. This tube is constructed utilizing multi-directional "uni" plies. This makes for a true workhorse of a tube with no frills. This tube is great for bending and compression applications however if you suspect this tube will be subject to general abuse in terms of abrasion / rocks etc. we would recommend you seek a fabric wrapped tube instead.

Features & Benefits

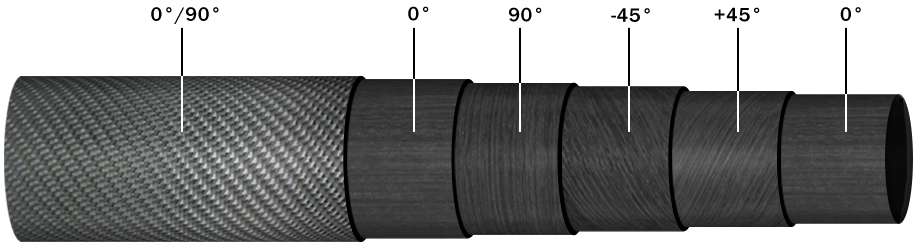

Roll wrapped tubing is manufactured using multiple layers of prepreg carbon fiber (and if noted, other) materials. In general each layer is about 0.006 inches thick which means that a tube with a wall thickness of 0.060 inches will typically be composed of 9-10 individual layers of carbon fiber. The number of layers (plys) allows us to vary the orientation of the fibers throughout the thickness, creating a high performance, engineered product.

*Please note, the diagram below shows an outer "0/90" ply however the product you are currently viewing does NOT have this outer twill ply.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup please check out the "LAYUP ORIENTATION" tab.

Additional Information

| Application | Bending |

|---|---|

| Shape | Round |

| Materials | Standard Modulus Carbon |

| Pattern | 3k 2X2 Twill Weave |

| Finish | Cello Wrap Gloss |

| Inside Diameter | 1.188 |

| Outside Diameter | 1.39 |

| Thickness | 0.125 |

| Length | 83.5 |

| Length (max continuous) | 83.5 |

| Weight | 1.51 |

| Temperature Rating (F) | 238.0 |

| Max Operating Temp- (Tg) | 225F to 249F |

| Resin / Chemistry / Polymer Type | Epoxy |

| HTS - Harmonized Tariff Code | 6815.13.0000 |

Technical Data

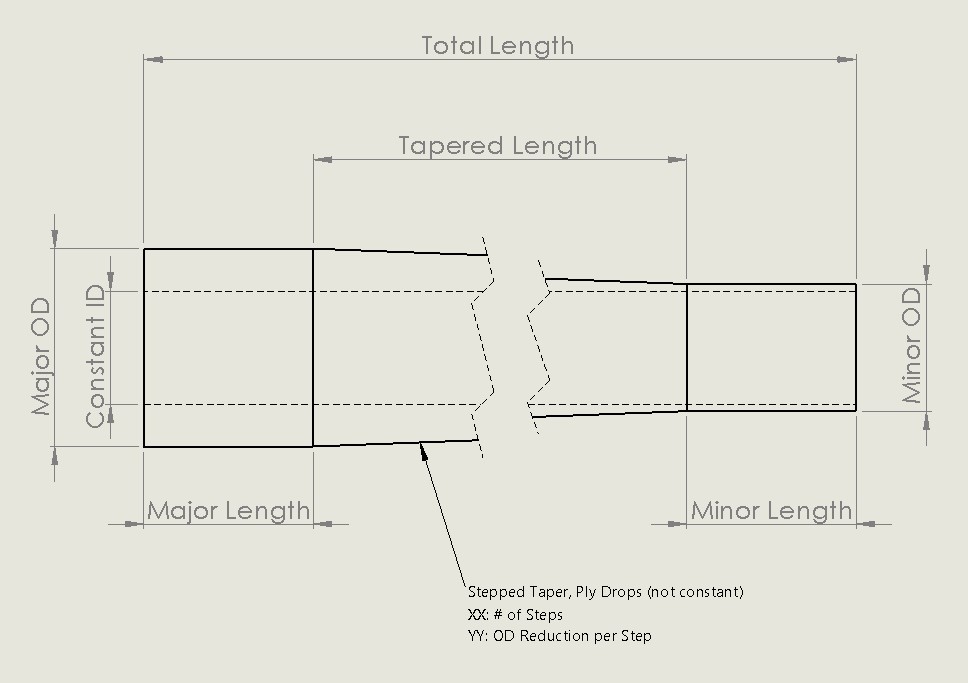

| Constant ID | 1.188" |

| Major OD | 1.392" |

| Minor OD | 1.273" |

| Major Length | 40" |

| Minor Length | 10" |

| Stepped Tapered Length via Ply Drops | 37.5" |

| Total Length | 83.5" |

| XX: Total # of Ply Drops (or "steps") | 10 |

| YY: OD Difference per Ply Drop (e.g. 2x prepreg ply thickness) | 0.012" |

Layup Orientation

46686-TPR

| Ply # | Orientation (degrees) | Location |

|---|

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.