Commercial Aircraft Components

QUALITY: QMS AS9100D/ISO9001:2015, Nadcap Composites, and Nadcap NDT standards.

SPEED: We fulfill expedited orders for Aircraft On Ground (AOG)

COMPLEXITY: We can complete complex first part qualifications (FPQ) and first articles per AS9102

QUALIFICATIONS: We have special processor qualifications for Boeing, Northrop, MD Helicopters, McDonnell Douglas, and ULA.

Contact us to support your program needs today!

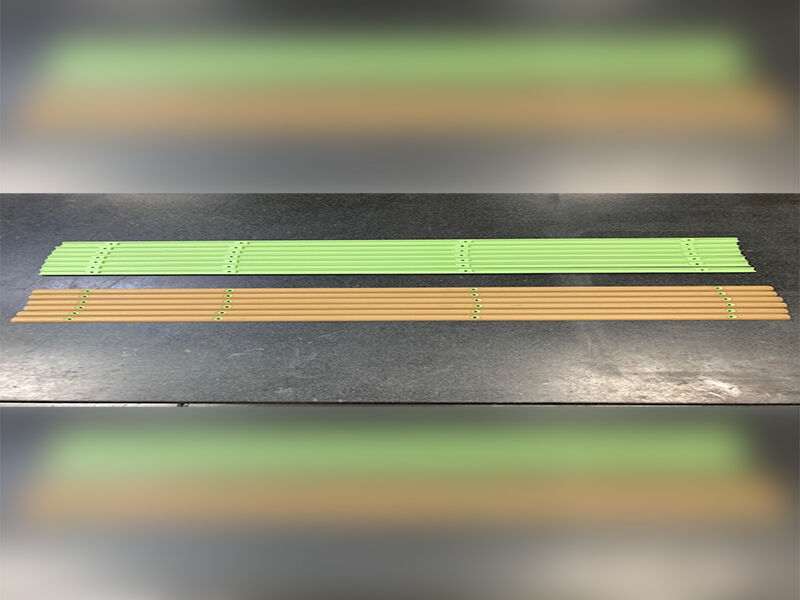

Composites

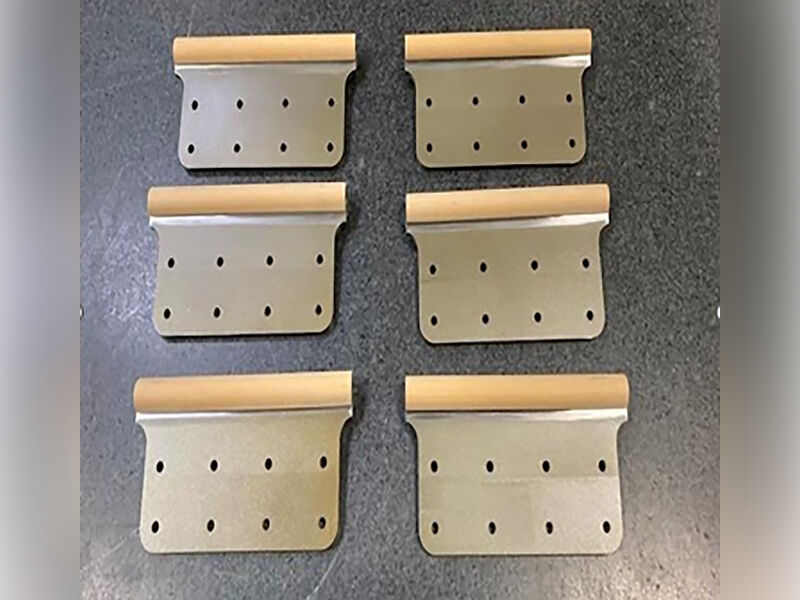

Metal Bond

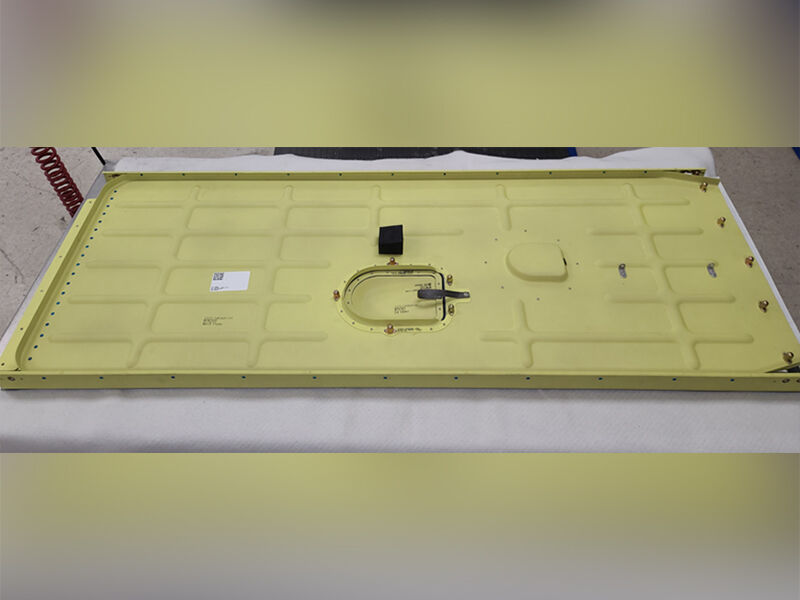

Sheet Metal Assemblies

Metallic Parts

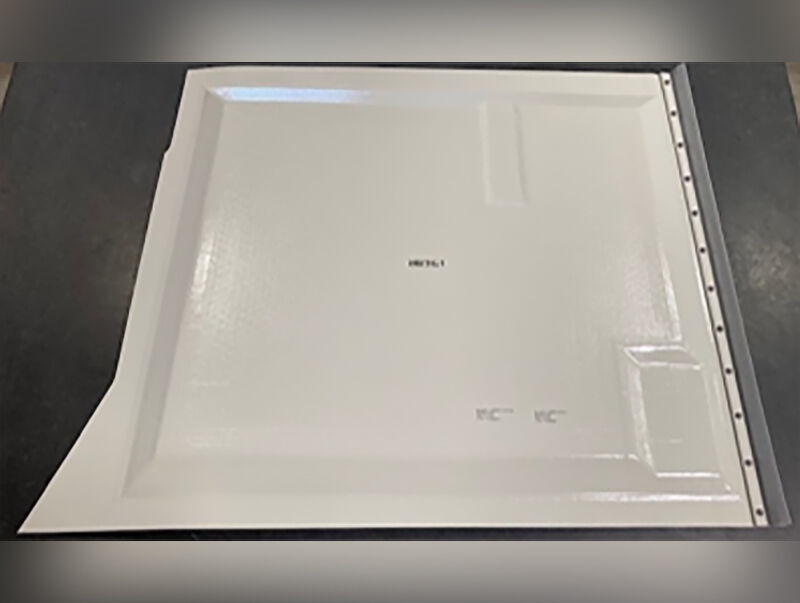

Vacuum Forming