Development

Rock West Composites develops new and innovative products that solve difficult problems and perform in extreme conditions. We work in many industries, offer comprehensive services, have in-depth materials knowledge, and create innovative designs. We’ll aid in the development of your project at any point of its life cycle, assisting in engineering and design, tooling, prototyping, and general management.

Experienced Team

Rock West Composites develops new and innovative products that solve difficult problems and perform in extreme conditions. We serve clients in diverse industries including aerospace and defense, national security, science and research, medical, energy, consumer and sporting goods, industrial, marine, and more.

Our development group has extensive experience in maximizing the use of advanced materials for high-performance applications. With an average of 20-years experience, our team has the creative problem-solving skills required to meet the most demanding requirements.

Development Methods

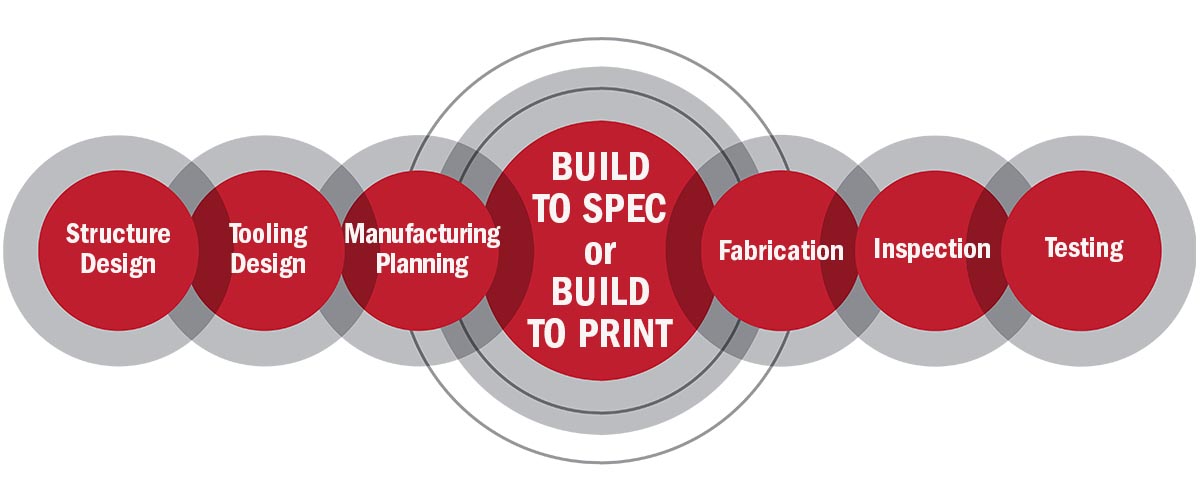

Our development methods support a variety of project types, suitable for any customer need.

Build to Print

Build to Spec / Design Authority / Design for Manufacture

Research and Development

Program Management

Our project management practices are rooted in industry-leading global standards.

- SAE; AS9100D, Aerospace Standards for Organizational Systems

- PMI; Project Management Body of Knowledge (PMBOK) Guide

- Our team is made up of highly technical engineers and managers with years of experience and formal project management training in many cases

A project lifecycle could be broken into 5 process groups across 10 knowledge areas. The lifecycle processes include:

Our project management processes address the following knowledge areas:

Development Process

Our team begins by:

- Assessing or helping to establish overall design requirements including strength and stiffness

- Identifying and addressing the key parameters that could drive performance, costs, risk, schedule delay, and other concerns

- Determining which components are candidates for composites

- Selecting materials and processes

- Defining and executing tests to measure or demonstrate capabilities

- Qualifying safety margins

Types of Engineering and Design Services

- Composite component design and optimization

- Laminates

- Sandwich structures

- Tool design

- Stress analysis and FEA

- Establishing inspection criteria

- Program management

Engineering Software

- SolidWorks

- Hyperworks and OptiStruct Finite Element Analysis (FEA)

- AcuSolve and Virtual Wind Tunnel Computational Fluid Dynamics (CFD)

- Anaglyph Ply Shaping Software

- MasterCAM CNC Machining Software

- AutoCAD Zemax – Optics

- MATLAB

- LabVIEW

- CREO