Composite Components for Energy Production

MAXIMIZING RESULTS: Modern living standards are energy intensive. Composites can help us maximize energy extraction and usage, whether it comes from above or below ground or is from single use or sustainable resources.

ENERGY TRANSITION: As the world converts from traditional to renewal resources, we must find ways to maximize the resources we have during the transition and moving forward. Whether it is higher efficiency exploration or capturing new energy sources, composites can get us to sustainable energy production.

Rock West’s Energy products currently fall in the areas of:

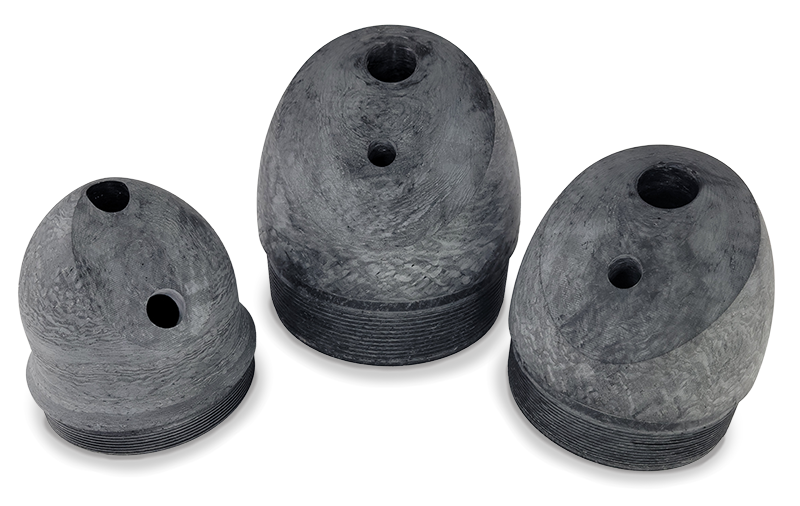

- Oil and gas completion

- Oil and gas cementation

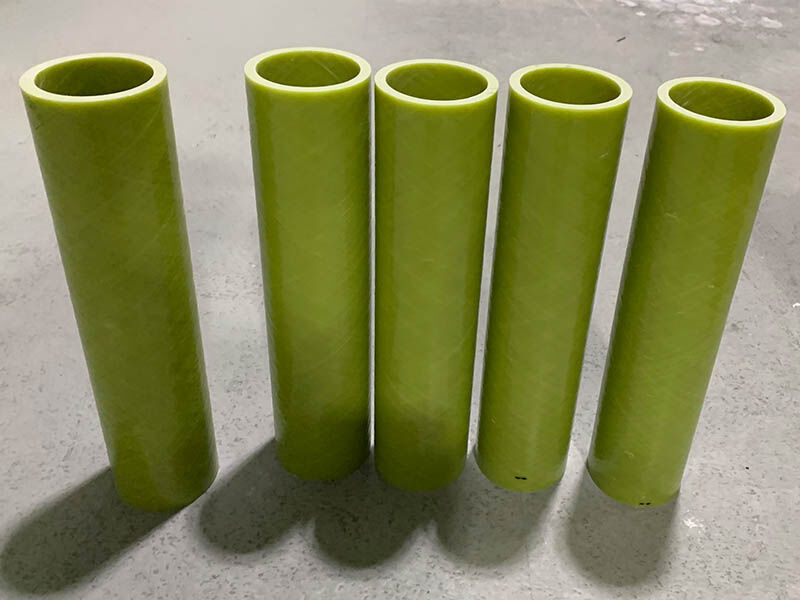

- Oil and gas tubulars

- Carbon capture

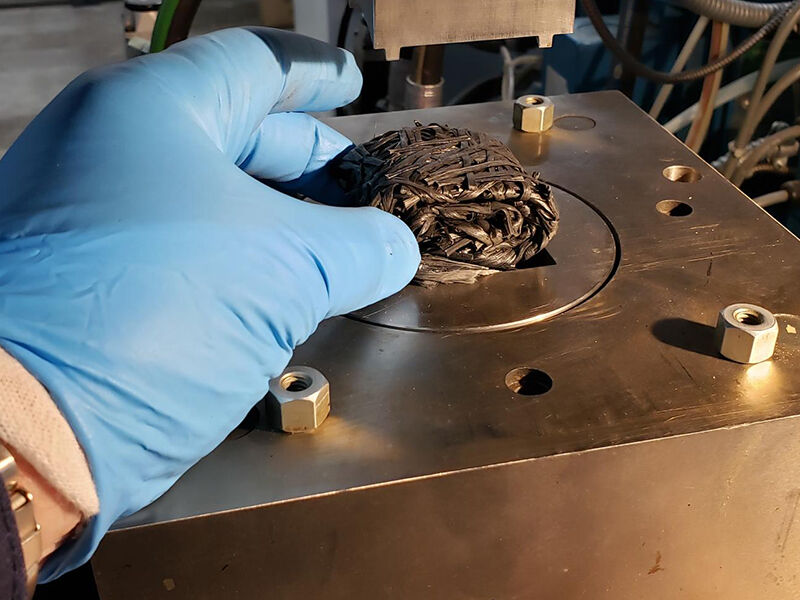

- Downhole Tools: Drilling / Wireline

- Artificial Lift