KyronMAX® Performance Structural Compound - Carbon Fiber Filled Thermoplastic for Injection Molding

High Physical Strength ◾ Ductility ◾ Heat & High Wear Resistance ◾ Low Moisture Absorption Option

KyronMAX® materials are lightweight and, when molded, parts are 75% lighter than steel and almost 40% lighter than aluminum. By utilizing the lower density of KyronMAX®, customers can simultaneously realize lower costs and lighter parts, while also taking advantage of unmatched tensile and toughness properties.

The better “practical toughness” values are achieved with lower filler loading, which increases the material’s elongation at yield. KyronMAX® molded parts are more likely to yield, rather than fracture under high-stress loads. KyronMAX® stronger fibers and lower filler loadings further elevate molded product performance with significantly better knit line strength compared to other filled polymers.

You may also need

Features & Benefits

Stronger than steel. Lighter than aluminum. Zero waste.

KyronMAX® is a range of new breakthrough high strength thermoplastic composite compounds, specifically designed for rapid, complex high-spec injection molding.

Easily processed, KyronMAX® can be molded using the same equipment and tooling as standard for unfilled resins, while compounds can be customized to meet application requirements. Crucially, where traditional materials struggle, KyronMAX® injection moldable materials retain high strength in complex part geometries, making them stronger, lighter and longer lasting (tougher) than other thermoplastic composite and metal parts.

A new standard in materials engineering

Strongest moldable polymers available for metal replacement applications.

The world’s strongest injection moldable product line of structural thermoplastic materials using advanced carbon fiber technology adds new formulas reaching 60,000 psi tensile strength.

Additional Information

| P/N | S-2220-20kg | S-2230-20kg | S-4230-20kg | S-4330-20kg |

|---|---|---|---|---|

| Application | Injection Molding | Injection Molding | Injection Molding | Injection Molding |

| Materials | PA66 (Polyamide) Nylon + Carbon Fiber | PA66 (Polyamide) Nylon + Carbon Fiber | PPA (High Performance Polyamide) Nylon + Carbon Fiber | PPA (High Performance Polyamide) Nylon + Carbon Fiber |

| Color | Black | Black | Black | Black |

| Length | 0 | 0 | 0 | 0 |

| Weight | 44.0 | 44.0 | 44.0 | 44.0 |

| Glass Transition (Tg, DMA) | 122F | 122F | 245F | 275F |

Technical Data

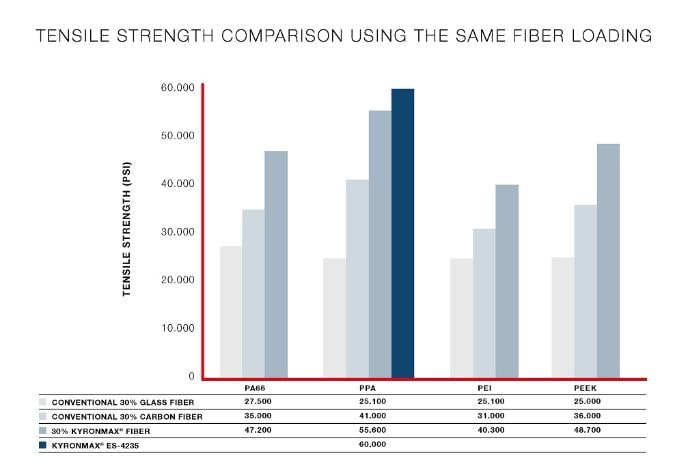

Tensile Strength Comparison Using the Same Fiber Loading

KyronMAX compounds exhibit much higher mechanical strength, than conventional glass and carbon filled systems, at the same fiber percentage loadings. The increased mechanical performance, allows the use of lower filler loadings, increasing the material’s strain, which allows the part to yield and not fracture.

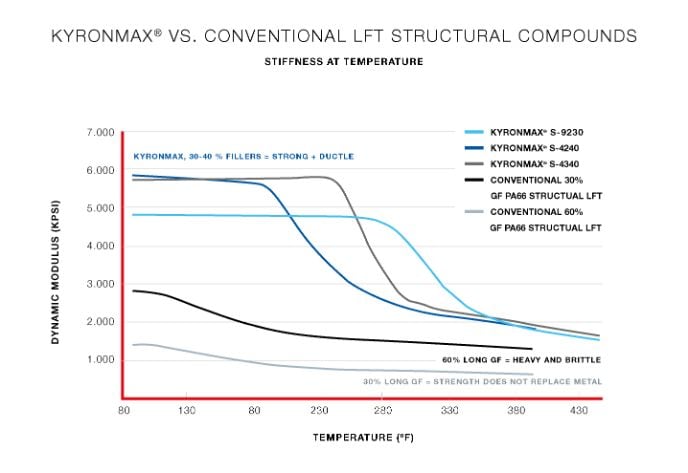

KyronMAX® vs Conventional LFT Structural Compounds Stiffness at Temperature

This standard Dynamic Mechanical Analysis (DMA) summary compares material stiffness over an elevated temperature range. As displayed, conventional glass and carbon filled Nylon compounds lose mechanical performance very quickly when exposed to even low elevated temperatures. In comparison, the KyronMAX products demonstrate excellent property retention even in the harshest of temperature regions.