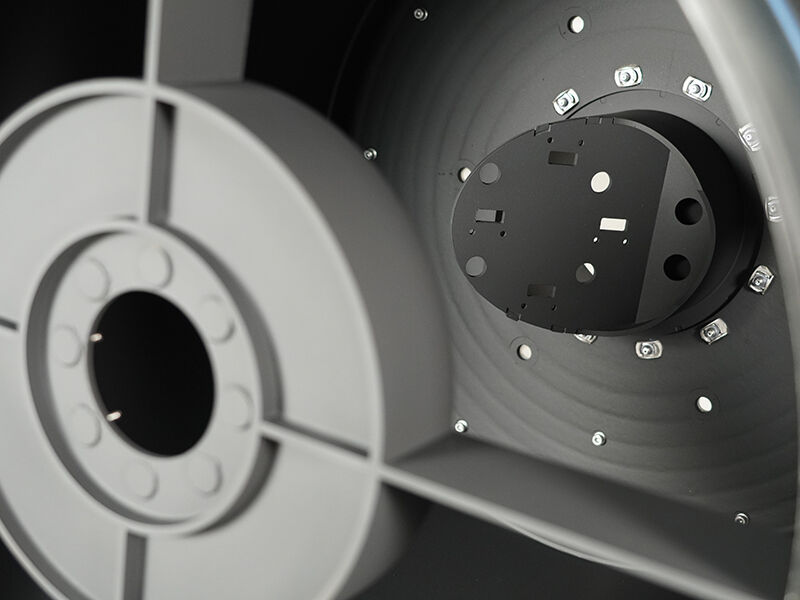

Payload, Optical and Deployable Structures

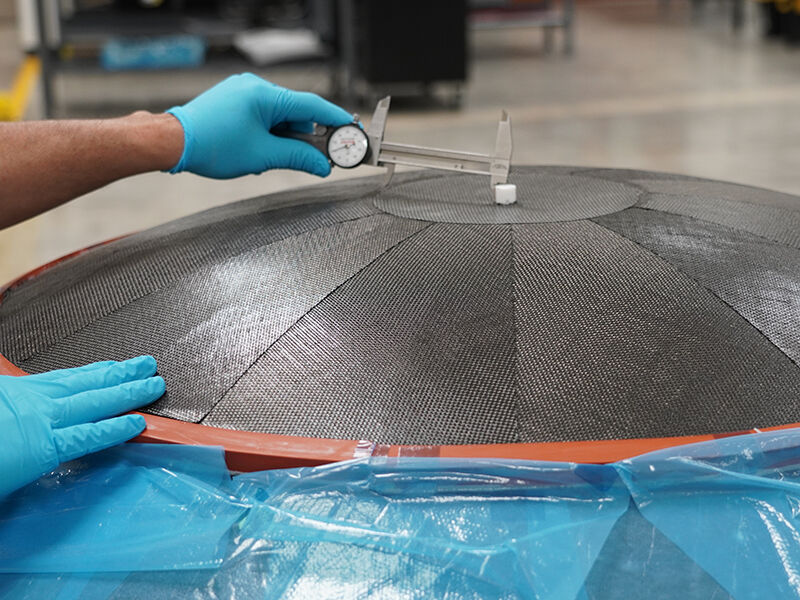

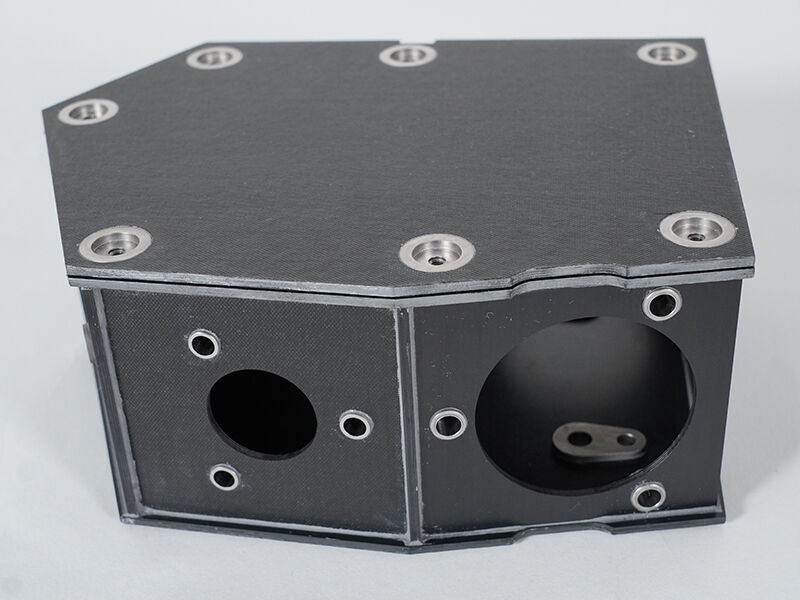

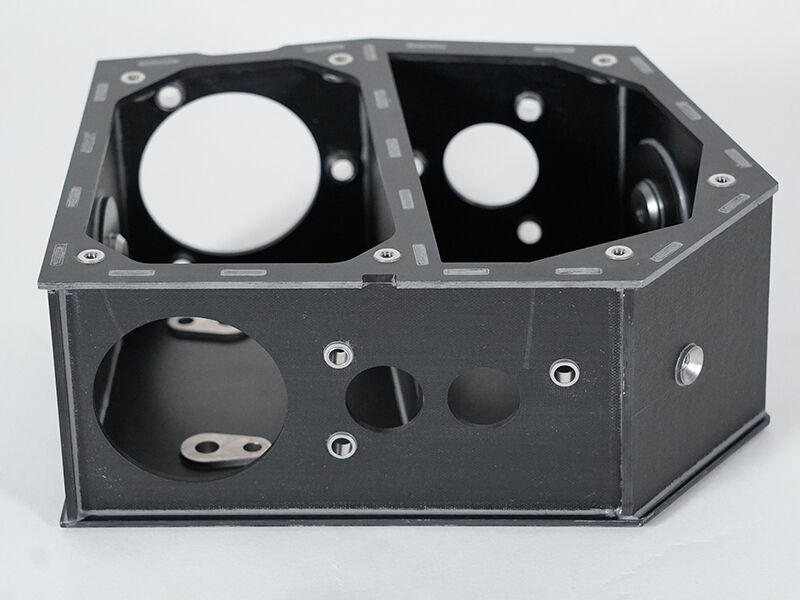

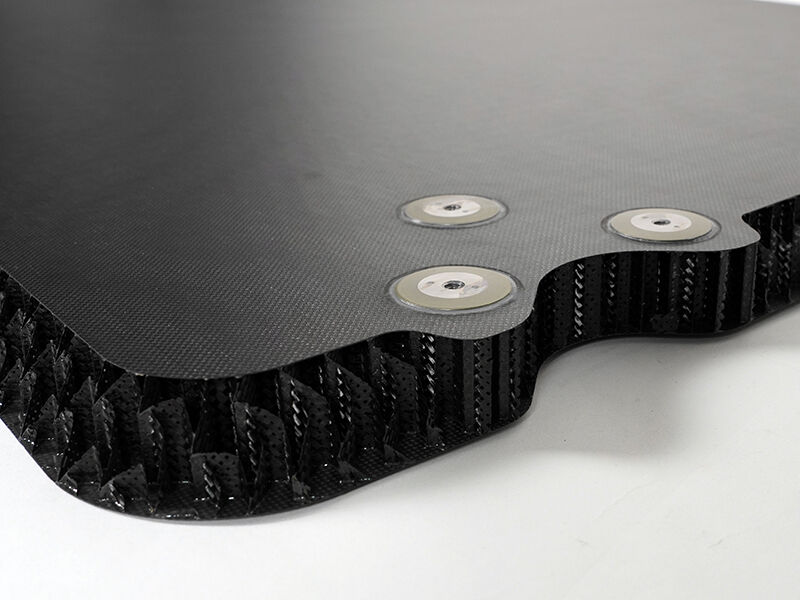

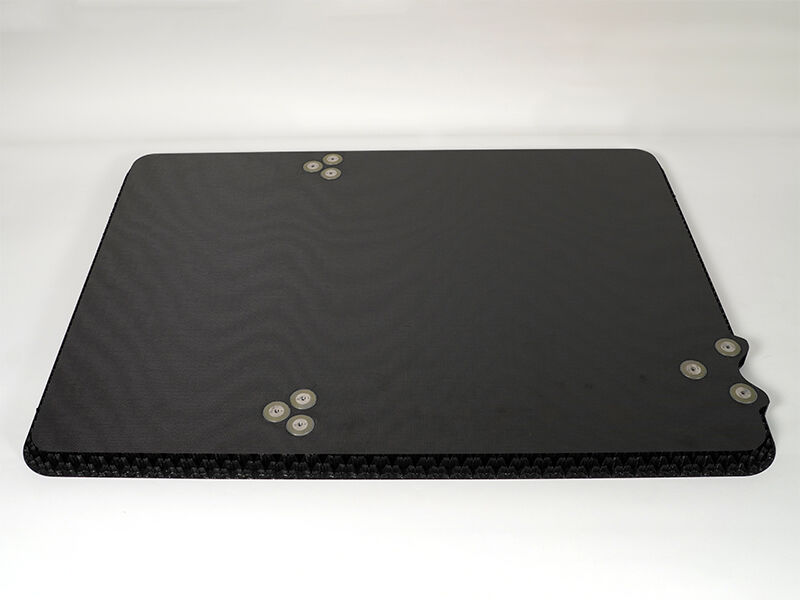

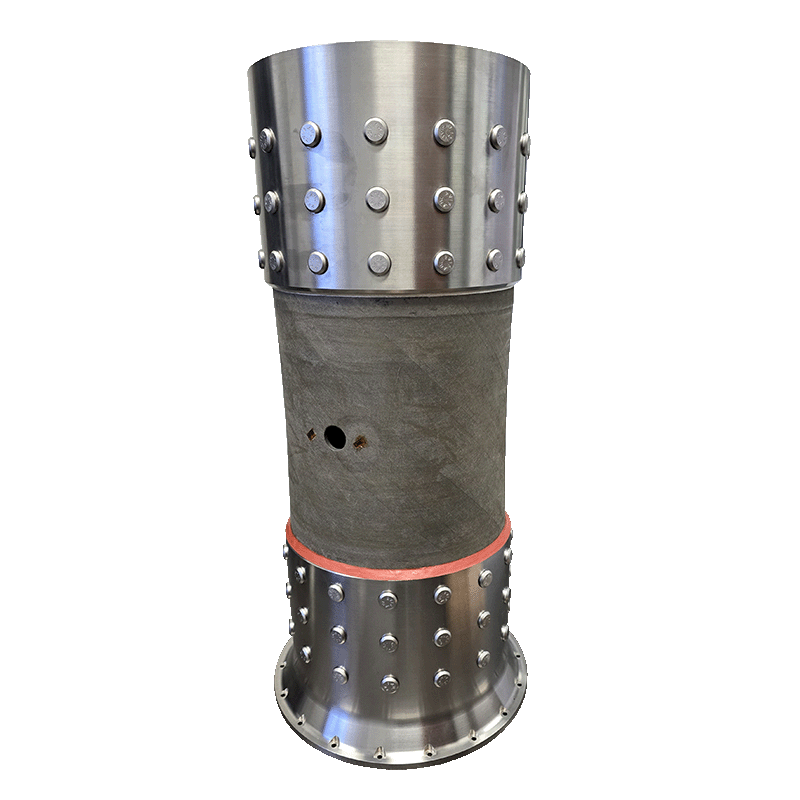

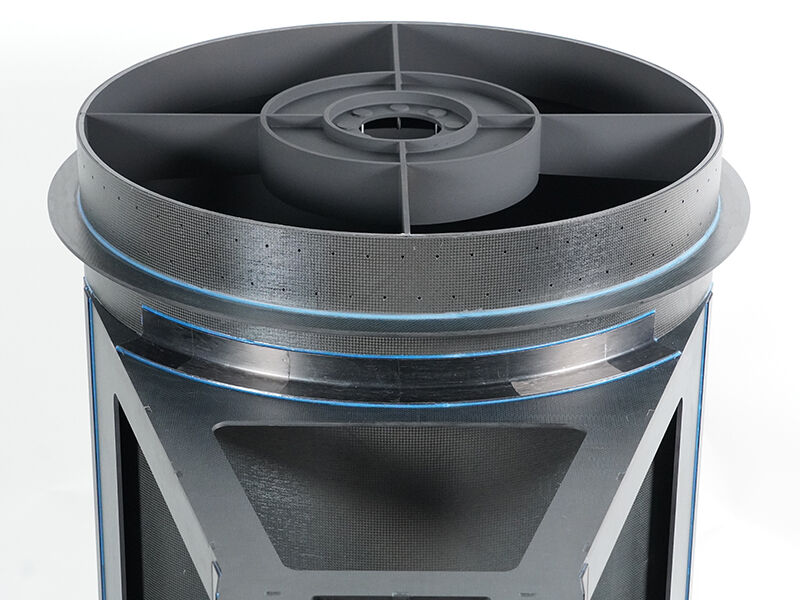

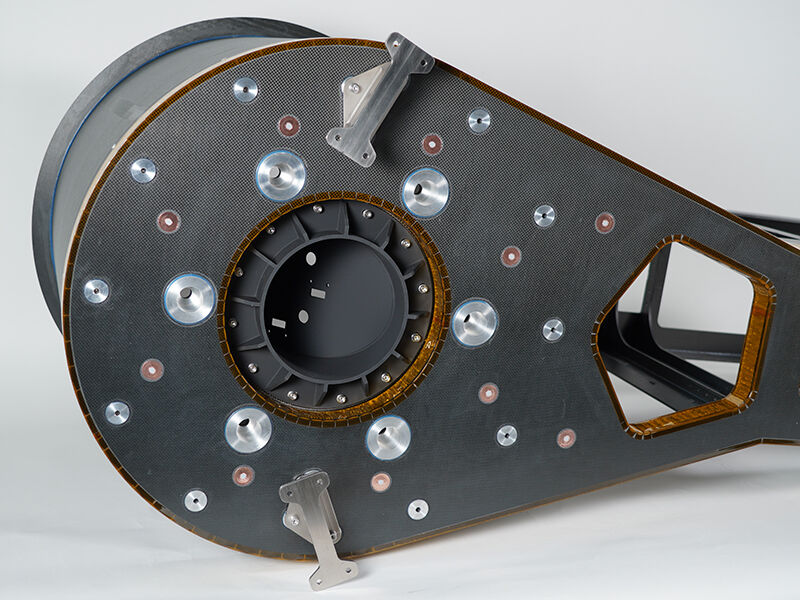

Our team has designed and fabricated a wide variety of payload, optical and deployable structures. This includes space telescopes, optical benches and metering tubes, deployable booms, reflectors, sunshades, and more!

GET AHEAD OF THE CURVE: We can include our STRATO™ line of products to accelerate schedule and reduce cost.