Radomes for Aerospace and Ground Applications

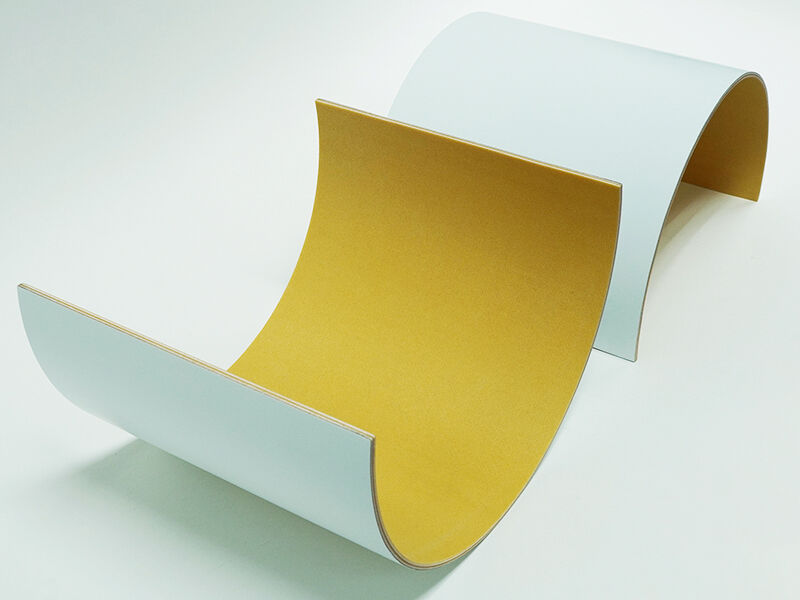

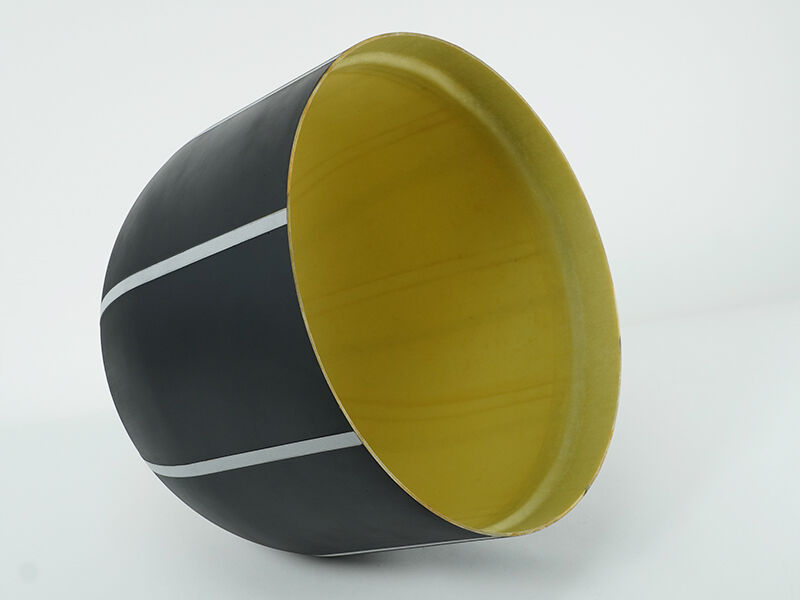

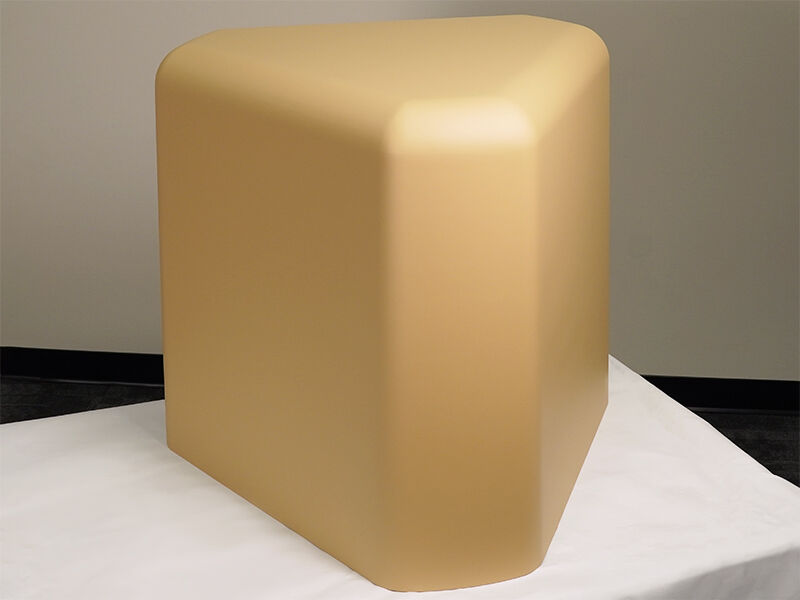

EXPERIENCE: Our team includes some of the best radome experts in the country. From low-cost to low loss to flight-qualified, from simple panels to curved shapes to multicomponent large-scale structures, we have the expertise to meet or exceed your technical requirements, while keeping cost and schedule in check.

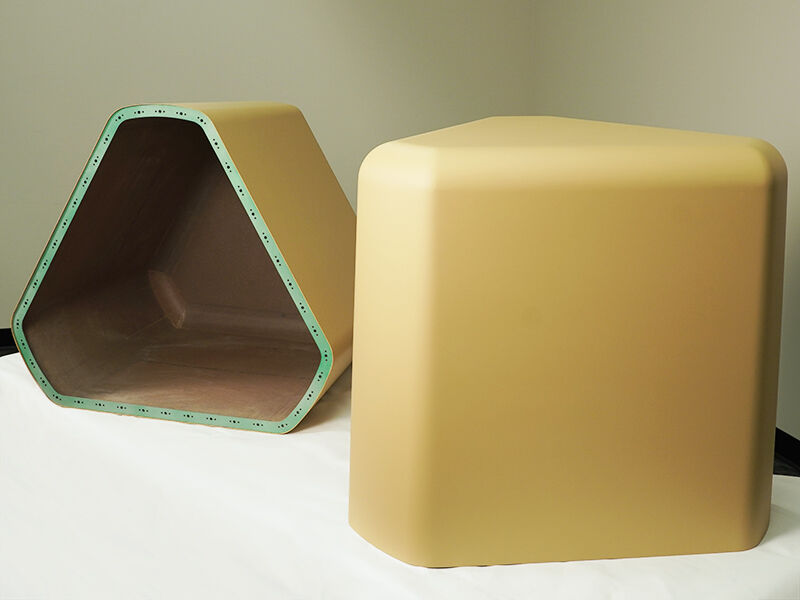

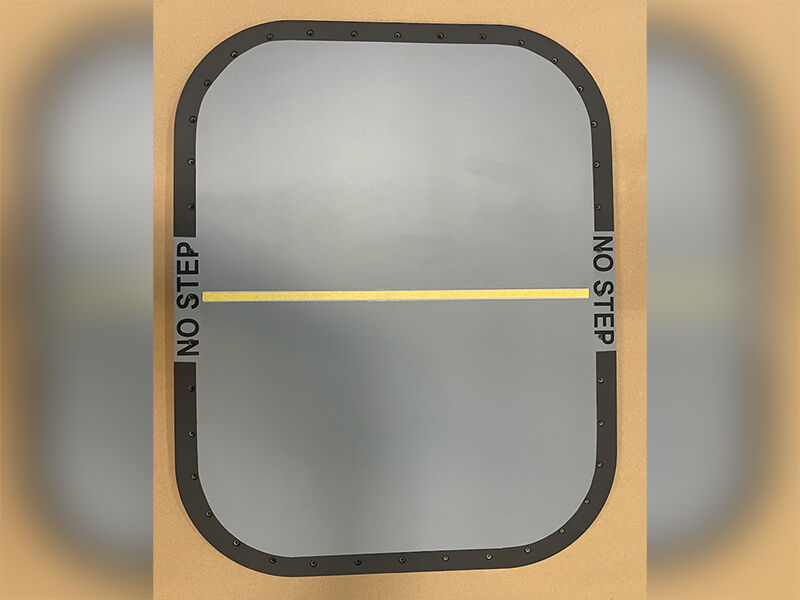

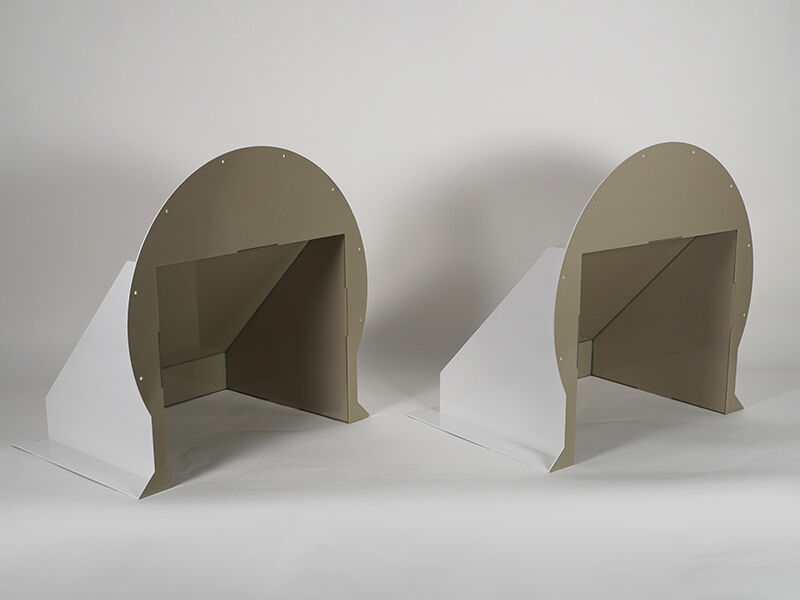

OUR WORK: We design, analyze, prototype, test, and manufacture low-cost ground, flight-qualified, and specialty radomes.

THE MATERIALS: Fiberglass, quartz, and high-temperature ceramic matrix composites. We can integrate metallic and carbon fiber components.

SPECIALTIES: UHF to 100 GHz. Using the right materials for your application. Tuning the radome to your specific bandwidths. High performance and low loss radomes.

Banner image credit: http://www.navair.navy.mil/img/uploads/GQM_163_COYOTE_Launch_in_France_4_APR_12.jpg. Use does not imply endorsement.

.jpg)