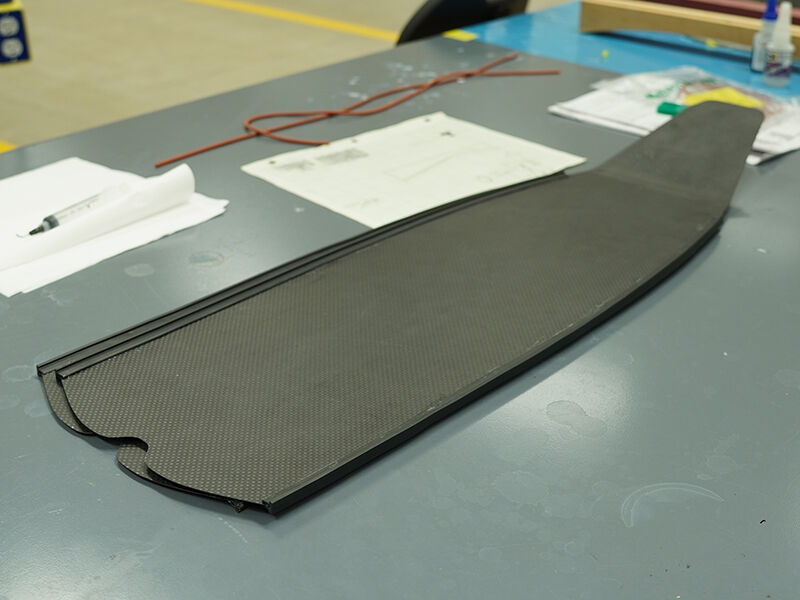

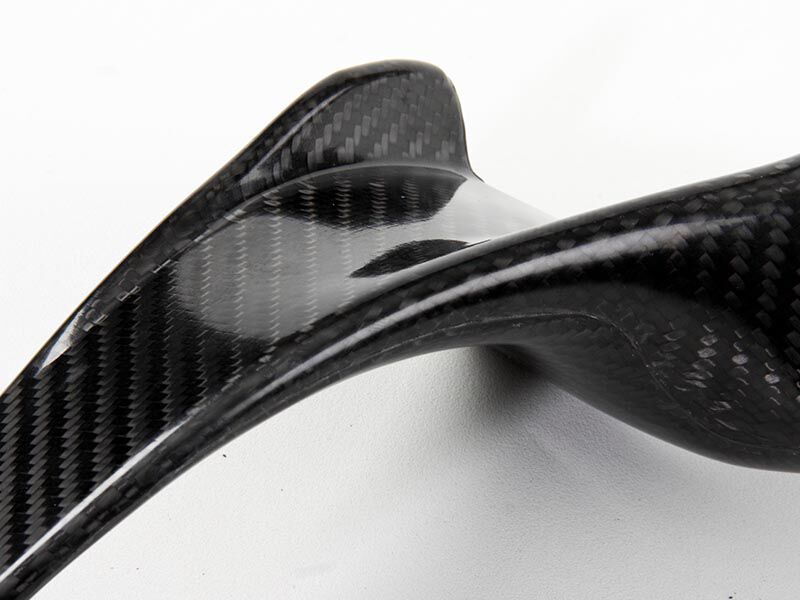

Sporting and Composite Components

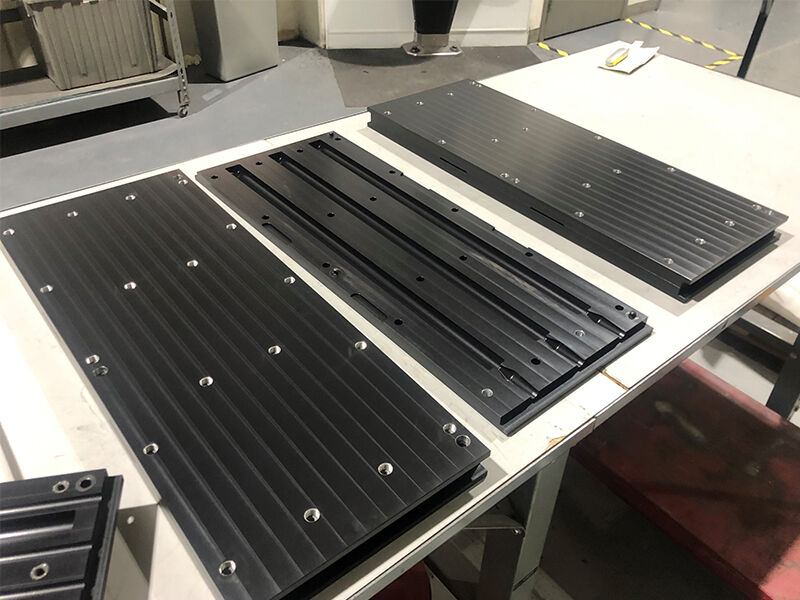

TAILORED SOLUTIONS: We find innovative ways to enhance specific performance requirements such as increased stiffness, lighter weight, etc., depending your specific needs.

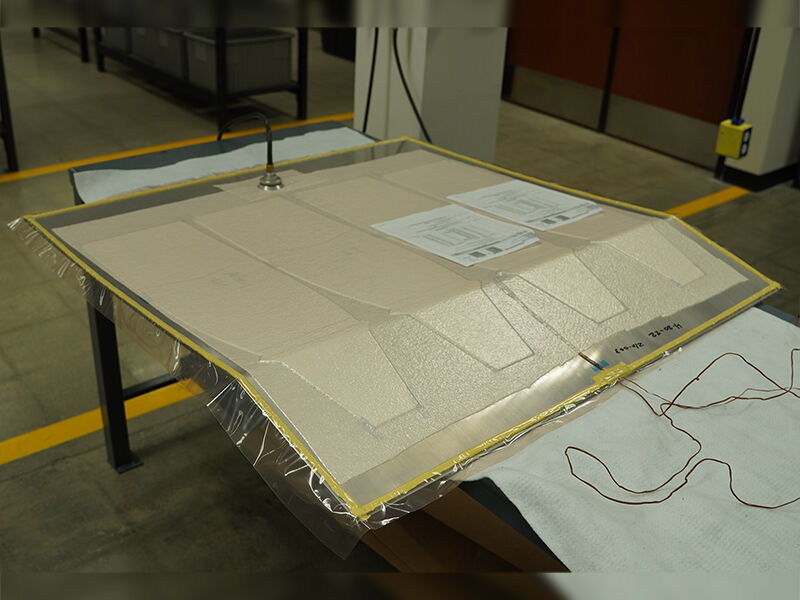

FULL PRODUCT LIFECYCLE: Designing, prototyping, testing, low to high volume production runs.

We do on-shore manufacturing in the US and Mexico. Our plants are all easily accessible and our operations are transparent. ISO 9001:2015 certified.