Tube - Square - Fabric - 1.375 x 1.45 x 66 inch

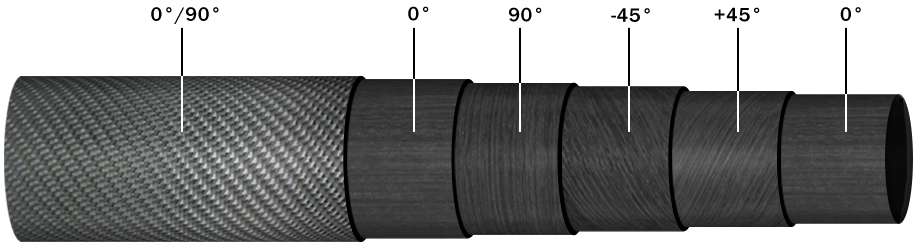

Unlike metals which have similar properties in all directions (isotropic), the properties of composites are varying, dependent on the orientation of the fibers in each layer.

- Fabric Tubing has an outer ply of woven material (denoted below as 0°/90°). Typically this outer ply is a 2x2 twill weave (diagonal appearance seen below) but it can also be a plain weave (small checkerboard), spread tow (large format plain weave / checkerboard) or other off-axis weave such as a braid. The core of these tubes are almost always comprised of multi-directional "uni" plies.

- Uni Tubing is comprised of multi-directional "uni" plies just like the fabric tubes however instead of the outer ply being fabric, it is unidirectional and most typically oriented at 0° (fibers running the length).

- To learn about our Roll Wrapping Process click here.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup please check out the "LAYUP ORIENTATION" tab.

Features & Benefits

Now you can apply Carbon Fiber to any surface with this high gloss, decorative adhesive backed Carbon Fiber Sheets.

These first quality carbon fiber sheets have a deep, glossy, three dimensional finish. The proprietary Autoclave process, 100% genuine carbon fiber prepreg (not a printed vinyl), and superior epoxy resin consistently deliver high gloss panels with outstanding strength, durability and a longer lasting mirror-like finish.

Our adhesive backed High Gloss Carbon Fiber Sheets are flexible, formable to curved surfaces, feature quality adhesive and can be trimmed with scissors for a simple peel and stick installation.

Applying the adhesive backing yourself can be a tricky process. We apply a high quality adhesive backing to the carbon fiber sheeting inhouse, using a cold laminator. The cold laminator provides a superior bond between the adhesive and the carbon fiber sheet. And the risk of handling an adhesive is eliminated.

You can save time and money by using these hassle free, ready-to-use carbon fiber adhesive backed sheets, available in multiple sizes for any project.

Project examples include:

- Dashboard inserts

- License plates

- Decorative phone faceplate

- Chassis, wings, bodies and full scale car applications

- Logo Decals and Emblems

- Instrument Decals

How to apply the adhesive backed Carbon Fiber Sheet.

These hassle free, ready-to-use adhesive backed carbon fiber sheets can be applied to any surface with an easy peel and stick installation. Simply cut out the desired shape, peel off the backing and firmly adhere the cut shape to the surface.

Preparing the Surface

Prior to applying the carbon fiber sheet, clean the surface to which the sheet will be applied. It is important to have a surface free of oils, grease and debris that could interfere with the adhesive.

We recommend using isopropyl alcohol as a cleaning agent. Make sure the surface is compatible with use of the solvent prior to cleaning. If unsure, using either a 50/50 alcohol water solution or liquid glass cleaner will suffice.

Clean the surface then allow to dry.

- First, draw the required shape on the sheet

- Cut out the shape with composite shears

- Clean the surface

- Remove the backing paper from the carbon fiber sheet

- Carefully place the sheet in the desired position

- Firmly smooth the sheet surface by hand

- Completed!

Additional Information

| Application | General Purpose |

|---|---|

| Shape | Square |

| Materials | Standard Modulus Carbon |

| Pattern | 3k 2X2 Twill Weave |

| Color | Black |

| Finish | Cello Wrap Gloss |

| Inside Diameter | 1.375 |

| Outside Diameter | 1.45 |

| Wall Thickness | 0.038 |

| Inner Corner Radius (approximate) | 0.21875 |

| Outer Corner Radius (approximate) | 0.234375 |

| Length | 66 |

| Length (max continuous) | 66.0 |

| Linear Density | 0.14 |

| Volumetric Density | 0.055 |

| Weight | 0.769 |

| Primary Fiber | Tenax UTS50 |

| Primary Resin / Hardener | Eporite EHM32 |

Engineering Properties

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

| Avg EX Young's Modulus | 1.095E7 |

|---|---|

| Avg EY Young's Modulus | 4366000.0 |

| GXY Shear Modulus | 1722000.0 |

| X Tensile Yield Strength | 68810.0 |

| X Compressive Yield Strength | 76680.0 |

| Y Tensile Yield Strength | 22040.0 |

| Y Compressive Yield Strength | 28180.0 |

| XY Shear Strength | 13580.0 |

| CTEX | 1.16E-07 |

| CTEY | 1.16E-07 |

| Poisson's Ratio vXY | 0.352 |

| Poisson's Ratio vYX | 0.14 |

- "X" is along the length of a tube, rod, plate, or panel.

- "Y" is around the perimeter of a tube, perpendicular to the length of pultruded parts, or along the width of a plate or panel.

Layup Orientation

25493 Rev NC

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | 0 | Inside |

| 2 | 45 | ↓ |

| 3 | -45 | |

| 4 | 0 | |

| 5 | 0/90 | Outside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.

Technical Data

Radius of Tubing

The inner and external corner radii are measured by hand with a radius gauge with no tolerance called out.- Internal Radius: 7/32”

- External Radius: 15/64”.

We cannot supply theoretical values for this tube at this time. For specification sheets and other data we can supply please review our Technical Spec page.

Layup Orientation

25493 Rev NC

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | 0 | Inside |

| 2 | 45 | ↓ |

| 3 | -45 | |

| 4 | 0 | |

| 5 | 0/90 | Outside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.