Tube - Hex - Fabric - 1.75 x 1.985 x 66 inch

Hexagonal cross section tubing offers fabricators and designers alike the ease of affixing motors, accessories and machined features since there is always a flat surface to work with. Offered in a variety of diameters and wall thicknesses one is bound to find a product that will suit your application. And of course, if you don't see what you need, let us know. We can likely build it.

Features & Benefits

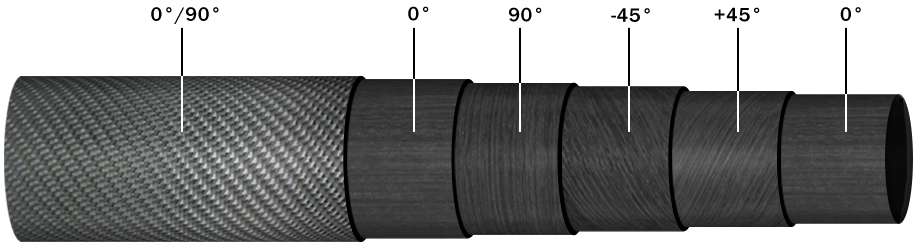

Unlike metals which have similar properties in all directions (isotropic), the properties of composites are varying, dependent on the orientation of the fibers in each layer.

Roll wrapped tubing is manufactured using multiple layers of pre-preg carbon fiber (and if noted, other) materials. In general each layer is about 0.006 inches thick which means that a tube with a wall thickness of 0.060 inches will typically be composed of 9-10 individual layers of carbon fiber. The number of layers(plys) allows us to vary the orientation of the fibers throughout the thickness, creating a high performance, engineered product.- Fabric Tubing has an outer ply of woven material (denoted below as 0°/90°). Typically this outer ply is a 2x2 twill weave (diagonal appearance seen below) but it can also be a plain weave (small checkerboard), spread tow (large format plain weave / checkerboard) or other off-axis weave such as a braid. The core of these tubes are almost always comprised of multi-directional "uni" plies.

- To learn about our Roll Wrapping Process click here.

*This diagram illustrates a "generic" layup. The SKU being viewed may not have the layup schedule shown in this diagram. To view this SKU's particular layup please check out the "LAYUP ORIENTATION" tab.

Additional Information

| Application | General Purpose |

|---|---|

| Shape | Hexagonal |

| Materials | Standard Modulus Carbon |

| Pattern | 3k 2X2 Twill Weave |

| Color | Black |

| Finish | Cello Wrap Gloss |

| Height | 1.985 |

| Wall Thickness | 0.118 |

| Major ID | 1.75 |

| Major OD | 1.75 |

| Minor ID | 1.75 |

| Minor OD | 1.75 |

| Inner Corner Radius | 0.046875 |

| Outer Corner Radius | 0.171875 |

| Length | 66 |

| Length (max continuous) | 66.0 |

| Linear Density | 0.499 |

| Volumetric Density | 0.055 |

| Weight | 2.744 |

| Primary Fiber | Tenax UTS50 |

| Primary Resin / Hardener | Eporite EHM32 |

| Max Operating Temp- (Tg) | 250F to 274F |

Engineering Properties

All laminate properties and mechanical calculations are based on Classical Lamination Theory and should be used as a reference only. Rock West Composites does not guarantee these properties or calculations.

| Avg EX Young's Modulus | 1.045E7 |

|---|---|

| Avg EY Young's Modulus | 6191000.0 |

| GXY Shear Modulus | 3118000.0 |

| X Tensile Yield Strength | 64980.0 |

| X Compressive Yield Strength | 73450.0 |

| Y Tensile Yield Strength | 37750.0 |

| Y Compressive Yield Strength | 45810.0 |

| XY Shear Strength | 27150.0 |

| CTEX | 1.38E-07 |

| CTEY | 1.57E-06 |

| Poisson's Ratio vXY | 0.342 |

| Poisson's Ratio vYX | 0.203 |

Layup Orientation

25611 Rev F

| Ply # | Orientation (degrees) | Location |

|---|---|---|

| 1 | 0 | Inside |

| 2 | 0 | ↓ |

| 3 | 45 | |

| 4 | -45 | |

| 5 | 45 | |

| 6 | -45 | |

| 7 | 0 | |

| 8 | 90 | |

| 9 | 90 | |

| 10 | 0 | |

| 11 | -45 | |

| 12 | 45 | |

| 13 | -45 | |

| 14 | 45 | |

| 15 | 0 | |

| 16 | 0 | |

| 17 | 0/90 | Outside |

- 0° fibers maximize bending stiffness and run along the length of the part. Consider bending a tube over your knee.

- 45° fibers maximize torsional stiffness and are typically plied together in an opposing manner, i.e. ±45°. Consider twisting a tube like a vehicle's driveshaft.

- 90° (or "hoop") fibers maximize crushing stiffness and generally assist in overall durability. Consider laying a tube on the ground and stepping on it.

Technical Specifications

Radius of Tubing

The inner and external corner radii are measured by hand with a radius gauge with no tolerance called out.- Internal Radius: 3/64”

- External Radius: 11/64”.

We cannot supply theoretical values for this tube at this time. For specification sheets and other data we can supply please review our Technical Spec page.