Industrial Applications and Composite Components

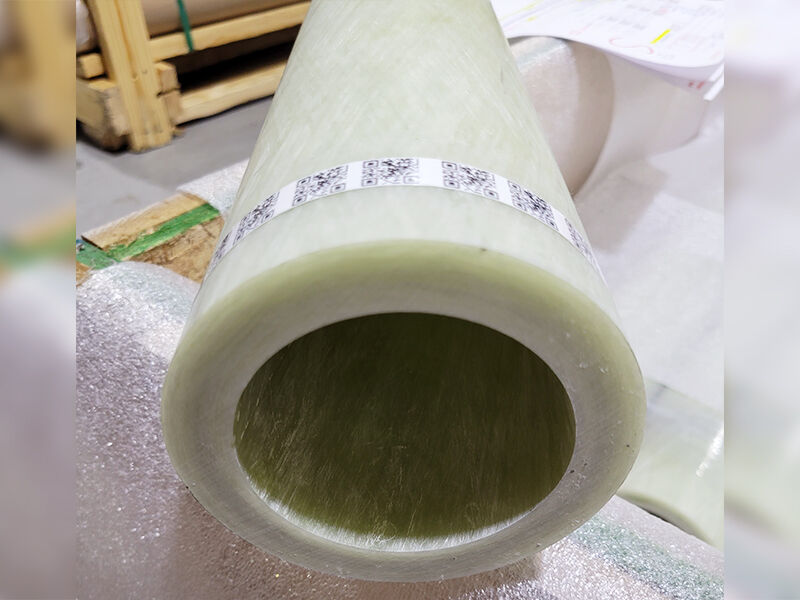

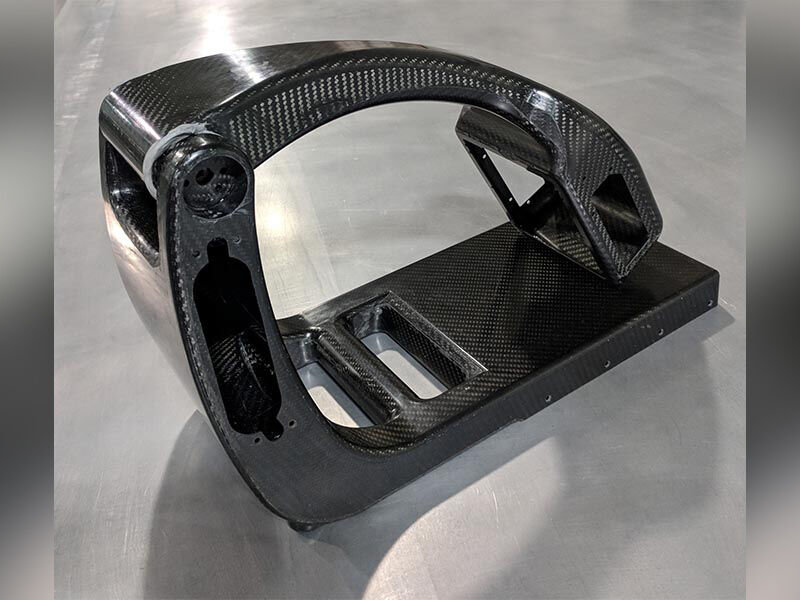

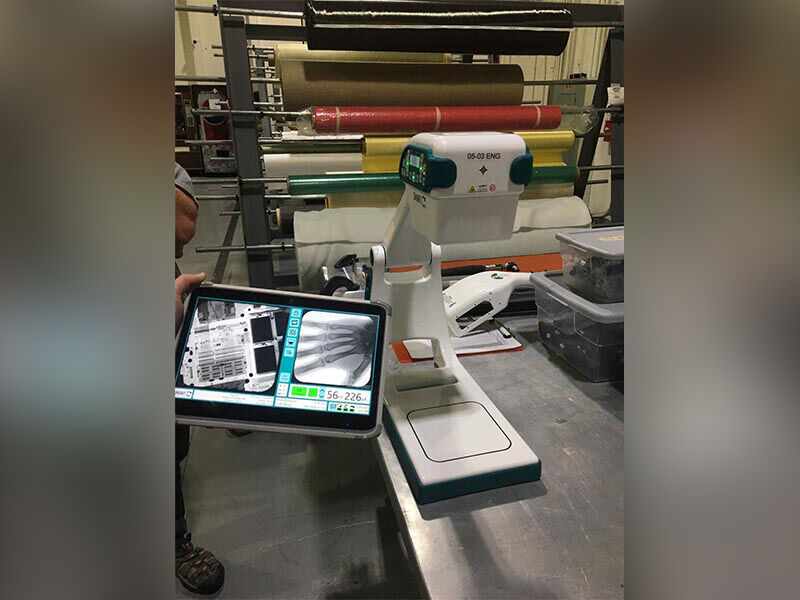

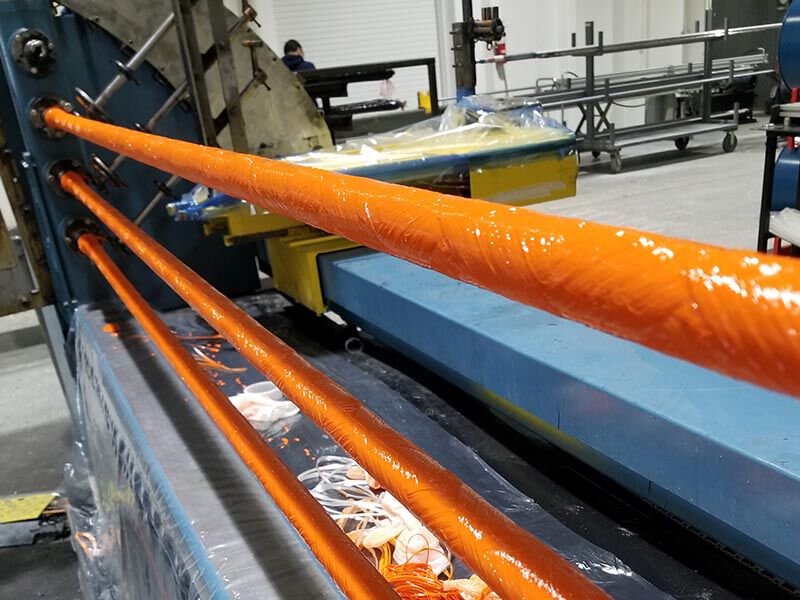

From industrial rollers to robotics and automation, an initial investment in composites can bring long-term cost savings through manufacturing precision and efficiencies.

The right materials can provide properties such as light weight, high stiffness, corrosion resistance, and stability through temperature changes (low CTE). These benefits can be realized from the small, lightweight applications to heavy industrial uses.

- Robotics and Automation

- Converting industry

- Automotive

- Agriculture

- Medical Equipment