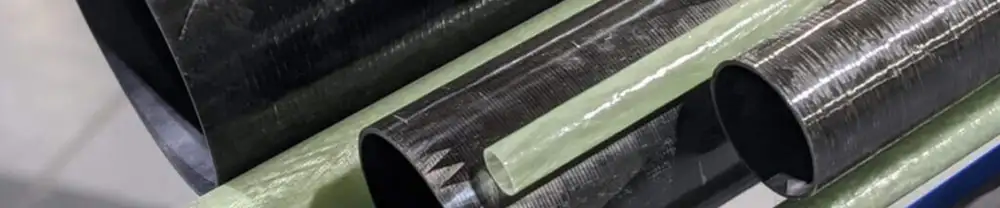

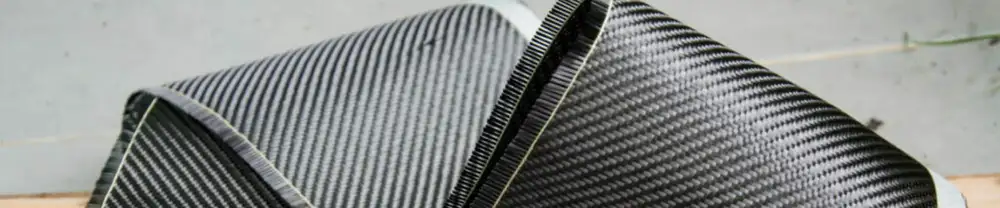

Carbon fiber is one of the most popular composite materials chosen to replace metals, woods, and weaker plastics. A carbon fiber reinforced polymer offers excellent tensile strength and rigidity at comparably low weight. As with every manufacturing material, there are right and wrong ways to work with carbon fiber.

If you are a seasoned fabricator, much of what you read in this post is probably already familiar to you. But if you are new to the carbon fiber game, the four tips listed here are particularly important. Knowing how to work with carbon fiber is as important as designing the parts you are hoping to build.

1. Handle with Care

Carbon fiber materials are quite strong and durable. Still, they can be damaged with improper handling. We always advise customers to handle their materials with care. For example, carbon fiber fabric should be kept in its original packaging until you are ready to use it. If you don’t use all the material in a single session, put what you do not use back into that original packaging.

The idea here is to ensure the material stays clean. If you allow it to get dirty, fabricating will be more difficult. Along those same lines, keeping dry fabrics and panels in their packaging eliminates the risk of loose fibers flying around. You want to keep loose fibers to a minimum.

2. Practice Proper Storage Techniques

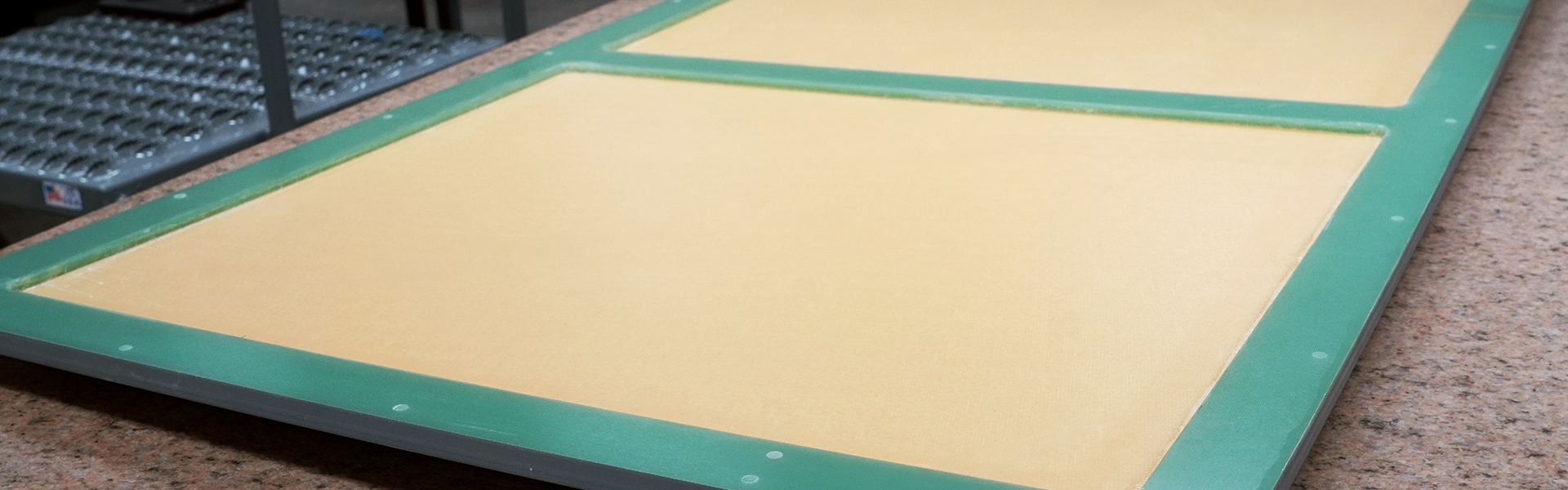

Next up, carbon fiber materials have to be stored in a certain way. Dry materials should never be stored in direct sunlight or where they can be exposed to moisture. Cool, dark storage locations are best for dry materials. If you are working with prepregs, it is important that you follow the storage instructions printed on the packaging.

Prepregs are carbon fiber fabrics that come from the factory already impregnated with epoxy resin. They must be stored in a cold environment to achieve maximum shelf life. Furthermore, they should not be taken out of cold storage until you are actually ready to begin a manual layup. If they sit around and get warm, the resin will begin to activate.

3. Wear Personal Protective Equipment

When you are actually laying up or machining carbon fiber materials, it’s important to wear personal protective equipment. The equipment you need depends on the task you are performing. If doing a manual layup for example, you will need eye protection and nitrile gloves at bare minimum. We recommend a mask as well. Always make sure your work area is well ventilated so that you are not overcome by fumes.

Cutting or machining carbon fiber parts calls for protective eyewear, heavy duty work gloves, and a mask. If you want to prevent loose fibers from getting in your clothing, wear an apron or smock as well.

4. Cleaning up Afterward

You are going to want to clean yourself up after handling carbon fiber materials. We recommend against simply brushing fibers and dusting off your skin as this could cause small pieces to embed themselves. Instead, warm water and soap will wash the debris away rather easily.

In the event you accidentally get epoxy on your skin, do not attempt to peel off. Instead, use a cloth or cotton swap to soak the area in vinegar. The vinegar will soften the resin so it can be washed off. Acetate also works well.

If you ever have questions about how to safely work with your carbon fiber products, do not be afraid to ask one of our team members at the time of purchase. We are here to assist you with all of your carbon fiber fabrication needs.

copy.jpg)

copy.jpg)