Latest News

We want our team to start the new year refreshed and ready to tackle the challenges ahead! So we be closed during the holidays for a two week break. From December 19, 2025 to January 5, 2026, our team will be out of the office. Shipping will resume January 6.

While we will do our best to ship in a timely manner, items ordered may not be delivered before the end of the year. If you have items under manufacture, please be aware that the holiday break will add two weeks to the production schedule.

May you have a restful and peaceful holiday season. We look forward to doing business with you in 2026 and beyond!

We are exhibiting at CAMX – the Composites and Advanced Materials Expo – the largest, most comprehensive composites and advanced materials event in North America. The conference is at the Orange County Convention Center in Orlando Florida on Sept 8 - 11, 2025. The Exhibition Hall is open Sept 9 - 11.

If you are attending, please come see us in Booth #E45!

We are proud to be a Contributing Sponsor. Be sure to catch presentations from our team who will be speaking the CAMX Theater Tuesday afternoon, September 9.

3:00PM – Space Grade Stock Materials - Rock West’s STRATO™ Products

Speaker: Jeremy Senne, Director – Space Structures Business

Jeremy will share an overview of how we’ve developed our flight-ready STRATO product line to service the need for extreme agility with the design, fabrication, and testing of high performance composite structures for the space arena. The product line provides for all the critical building blocks for satellite BUS structures, solar array panels, and telescope structures.

3:30PM – High-Performance, Low-Cost Composite SAS and BUS Panel Property Characterization

Speaker: Mason Souther, Lead Test Engineer

Mason will share details on composite material characterization of our STRATO line of sandwich panels and plates, and how manufacturing processes impact their performance. By leveraging material commonality across their stocked material systems and internal testing capability, Rock West Composites can offer customers improved certainty during the design and manufacturing process.

We look forward to seeing you there!

FOR IMMEDIATE RELEASE

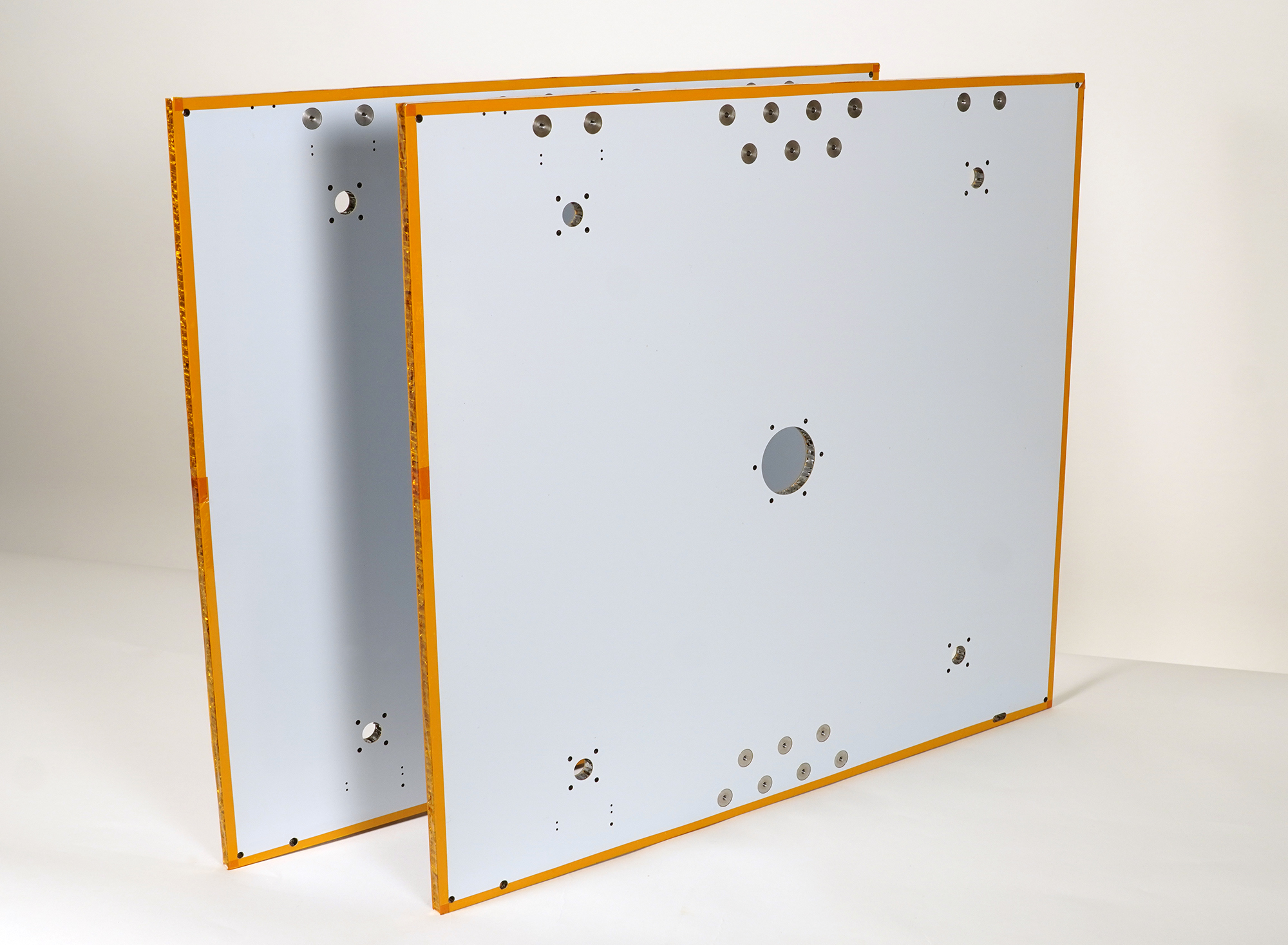

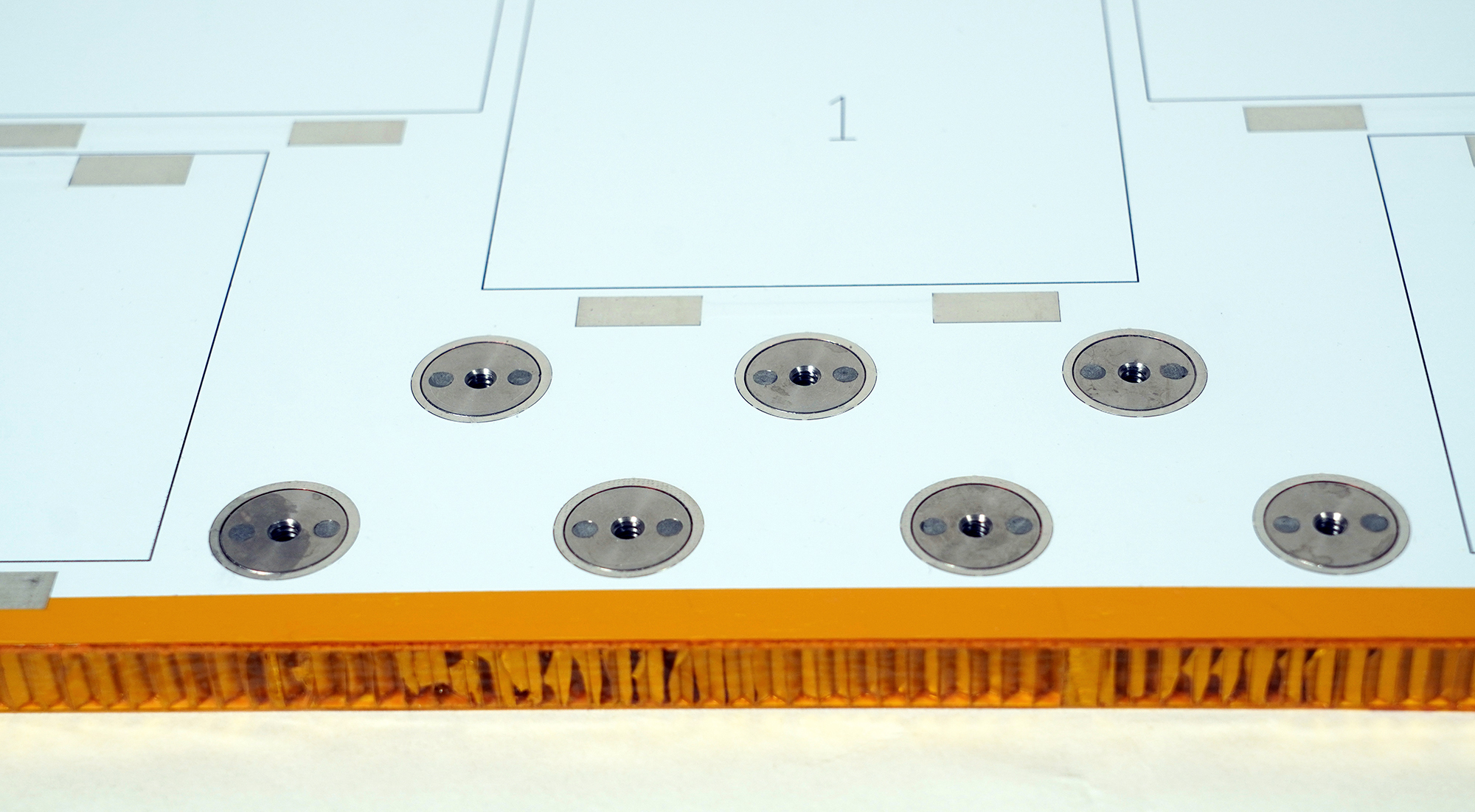

Rock West Composites Delivers Panels for 500-Watt Arrays to Astro Digital for their Higher-Power Buses This month Rock West Composites delivered panels for Astro Digital’s new 500-Watt arrays to support higher power versions of Astro Digital’s Corvus buses. RWC built the sandwich panels from trace/lead integrated skins that allowed for direct integration with solar cells, saving weight and integration time for the customer.

San Diego, CA (PRWEB) June 27, 2024 – Rock West Composites (RWC) announces the delivery this month of panels for Astro Digital’s new 500-Watt arrays to support higher power versions of their Corvus buses. RWC teamed with Astro Digital to fabricate solar array substrate (SAS) panels with a unique integrated design to save volume and weight. These panels are being integrated into space vehicles, the first of which is scheduled to launch in October.

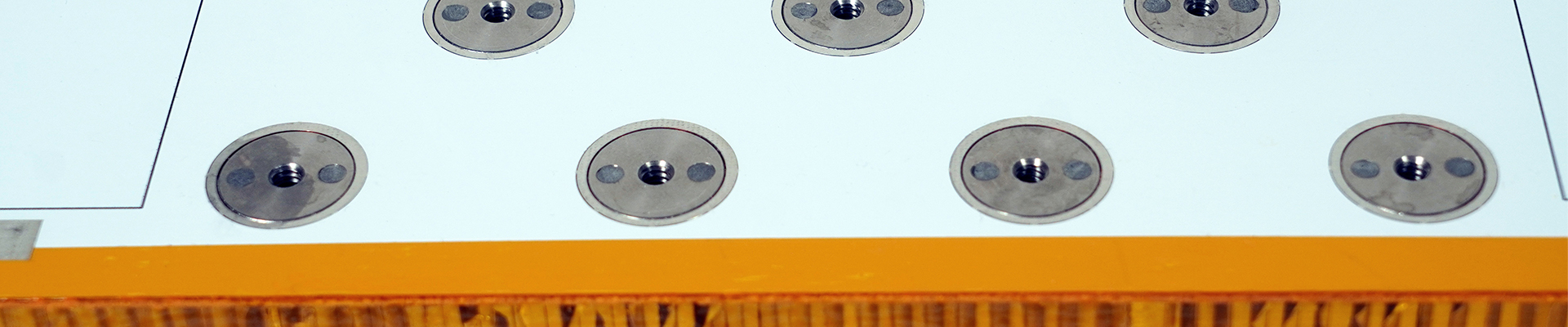

These SAS panels are unique in that RWC built the sandwich panels from trace/lead integrated skins that allowed for direct integration with solar cells. This reduced total weight and shortened the integration time. The customer furnished the G10 (fiberglass) skins that already had the integrated copper traces. RWC used specialized tooling to align the face skins on the aluminum honeycomb core to keep the traces in the right location during fabrication of the approximately 2’ x 2’ structures.

Jeremy Senne, Space Segment Director, said, “This is a great example of how we can help our customers solve their problems in innovative ways. It was a tooling and machining challenge to work with their pre-integrated skins, but our experience on other precision programs enabled successful fabrication.”

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Space (bus structures; solar array panels and wings; launch vehicle structures; optical, payload and deployable structures), Aerospace & Defense (radomes, munitions, unmanned systems, reflectors), Aircraft (new and replacement parts) and Commercial Equipment (automation, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s mission is to make customers more competitive with the magic of advanced composites by delivering highly differentiated products on time and on budget, all while making the buying process easy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Marketing Director

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

Our Ecommerce Origins Story

In 2009, rockwestcomposites.com became one of the first online merchants for carbon fiber tubes, plates, panels, connectors, and materials. Over the past 15 years, our value proposition has always been that more than 94% of the items we stock ship within 24 hours. While this quick ship promise is great for last-minute needs, the fluctuation of demand forced us to continually scale back the number of items we listed for sale. While Rock West Composites owns over 3,000 mandrels, we were listing under 1,600 tubes for sale.

New Product Success

In 2023, we tried something different. We the first-of-offered-its-kind selection of off-the-shelf, space-ready items called STRATO™. Our value proposition was no longer centered around 24-hour shipment. It stated that we had the materials, tools, certifications, and people power to produce these standard items in 4-6 weeks, far faster than a custom solution. This approach allowed us to offer a far larger selection of tubes, plates, panels, and materials to our customers than if we tried to make them and keep them in stock. The product has been very successful. We've helped numerous customers shave weeks off their schedules while enjoying the cost benefits of using a stock item versus a custom solution.

Sitewide Product Expansion with Rapid Production

Building upon the success of the STRATO™ program, we are expanding this concept into everything we do. While we will continue to stock fast moving items, we will also list many items that we have the materials, tools, and peoplepower to produce quickly upon your order. Almost all items will be available within 4 weeks of order placement. We are also expanding the number of raw components we sell and are actively engaging with other manufacturers to sell their products on our site. We want rockwestcomposites.com to be your one-stop for everything you need to complete your advanced composites project.

Plan on Success!

We are excited about these changes as we believe they will provide you, our customers, access to significantly more off-the-shelf solutions for your projects. And while you will have to plan and order a little further in advance, you will have many more items to choose from. As always, if you do run into a time crunch, let us know. We may have alternative solutions or expedited services that can meet your deadline.

New Website in May

We are targeting May for our website launch. Please check out the new site, and if you don't see a product that you think we should be carrying, drop us an email at marketing@rockwestcomposites.com, and we'll do everything we can to add it.

Telescoping tubing has so many practical uses and can be used in everything from window washers to selfie sticks. But sometimes you can't find the right length you need for your purposes. While building your own set can get you exactly what you want (and we are happy to provide all the supplies you need to do it), the process can be time consuming to design and assemble the structure. We have a great solution for you! We now offer fully assembled telescoping tubing from two of our lines: INFINITubeV and INFINITubeUL .

Our INFINITubeV Telescoping Tubes provide the perfect balance of strength and lightweight design. This product utilizes our standard modulus tubes, with a classic carbon fiber twill weave strength and esthetic. Engineered for seamless extension and retraction, these tubes offer unmatched versatility for a range of applications, providing exceptional strength without the added weight of heaviest material. For this line, you can choose between our compression ring twist clamps or our new proprietary Flip and Twist locking clamps (more details below!).

Our Ultralight Telescoping Tubes utilize standard modulus unidirectional tubes and provide the strongest strength to weight ratio of our telescoping tube options. This set provides the same seamless extension and retraction, versatility and strength. This is just much lighter. This model utilizes compression ring twist clamps.

Both of these lines have medium, long, and extra-long options with 3, 4 or 5 segments respectively. The collapsed and extended length depends on the line since each line has different tube lengths. For details, review the specifications on the individual product pages.

Compression ring twist clamps (left) and our flip and twist locking clamps (right)

NEW Flip and Twist Locking Clamps

These flip and twist locking clamps are made specifically to work with our INFINITubeV Telescoping Tubes , and they are faster to lock and release than our compression ring twist clamps. They are manufactured with PA12GB 40% glass filled & blacked nylon, meaning it has high stiffness and temperature resistance. If you are building your own telescoping tube set, these clamps can be secured to the base (larger) tube in the assembly with a cyanoacrylate adhesive or the supplied screw (for dis-assembly). But why build your own when you can buy it assembled already ?

We are constantly thinking about the types of projects on which our customers might be working and also about what sort of products they might need to achieve their finished handiwork. So we have just added to our store two products you might find useful in your projects!

Forged Carbon Fiber Blocks

These forged blocks are made with very small chopped carbon fibers and resin and then put at immense pressure as the resin sets. The result is a very strong block of material with isotropic properties.

We offer a variety of thicknesses, and these blocks are fully machinable. They can also be hand shaped using abrasive Dremel tools and sandpaper. Rock West offers machining services for customers who need assistance.

Key Points:

- The blocks have isotropic strength

- They are fully machinable and can be shaped

- Thicknesses range from 0.05″ to 3″

Learn More About CF Blocks!

DIY Resin Infusion Kits

We have put together five different sized kits for infusing your own carbon fiber parts. All kits include tubing, COMPOFLEX flow media, vacuum bag material, sealant, and resin infusion hubs. Carbon fiber fabric comes with the three larger kits. Resin and hardener is included in the two largest kits.

These kits are great for the DIY enthusiast who is carbon fiber curious or a seasoned carbon fiber hobbyist who already has some necessary supplies on hand. This can also be a great buy for educational institutions.

Key Points:

- There are five levels of kits to fit your project needs

- You can save money with the kit, which is less than the price of buying all the individual components

Learn More About Our Resin Infusion Kits!

Our forged carbon fiber blocks are currently in stock, and our resin infusion kits are put together when you order. Order today and dive into a new project this summer! We’d love to see what you create, so send our customer service team an email with a picture and description of your project at customer.service@rockwestcomposites.com. Have a great creative summer!

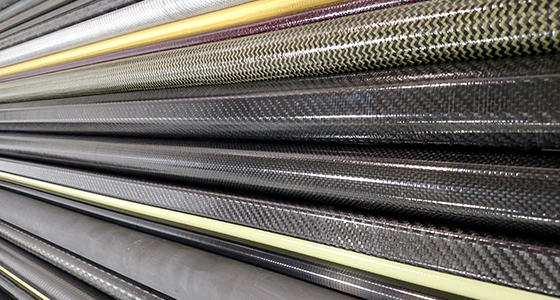

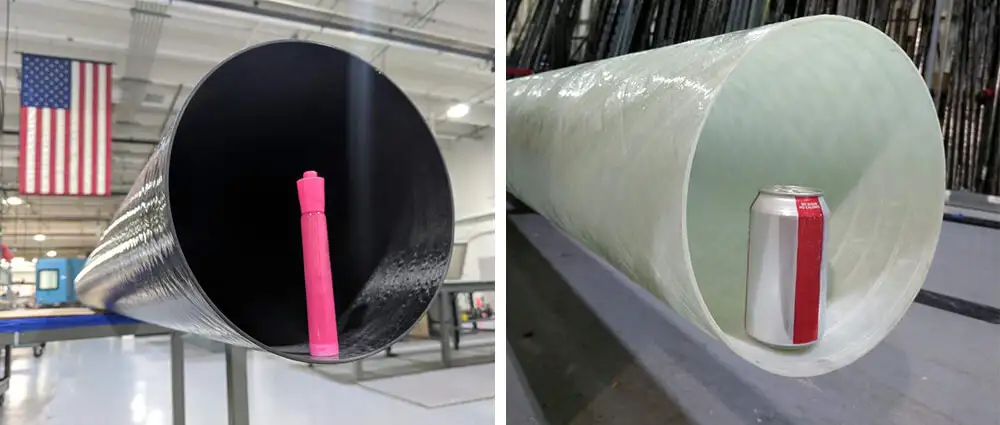

We carry one of the widest selection of tubes available anywhere, with options of varying sizes, materials, properties, and shapes. Even with this incredible variety, we know our selection of off-the-shelf tubing is more limited for large diameter tubes. So we offer a service to cover this spectrum of products – you can Build Your Own Tube!

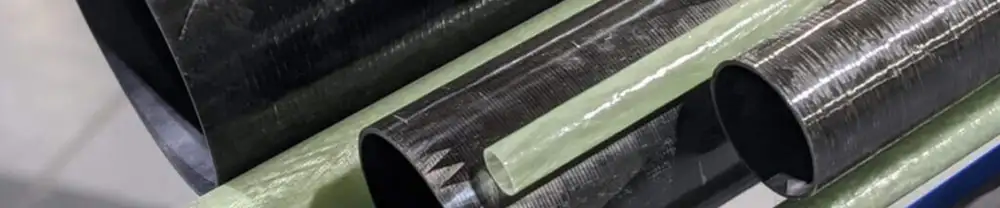

We have an online tube builder for larger diameter options. You may have seen this before on our website, but we have made some recent improvements. This calculator allows you to order filament wound tubes to your specifications for sizes ranging from 0.999” to 21.532” in diameter and up to 29 feet long. We have 42 mandrels to choose from and in the future, we may add more!

Large diameter custom composite tubes

Do you have specific structural requirements? You can choose a winding and lay up technique that optimizes your tube for lateral strength, torque, or internal pressure.

Do you have temperature-related operational needs? These tubes can be created for either standard temperature ranges (223°F max) or for high temperature resistance (up to 400°F).

What material will support your end-use application? Our tubes can be wound with fiberglass or intermediate carbon fiber; it’s your choice!

What’s new? Because the tubes are wound on a full mandrel and then cut to the length desired, we can maximize material efficiencies, creating cost savings that we pass on to you. Given a desired length, the tool will calculate the optimal number of tubes to create the best price per tube.

Even better, the finished parts take about 2 weeks to complete and ship. So if you want a larger tube and can’t find the specifications you want, build it!

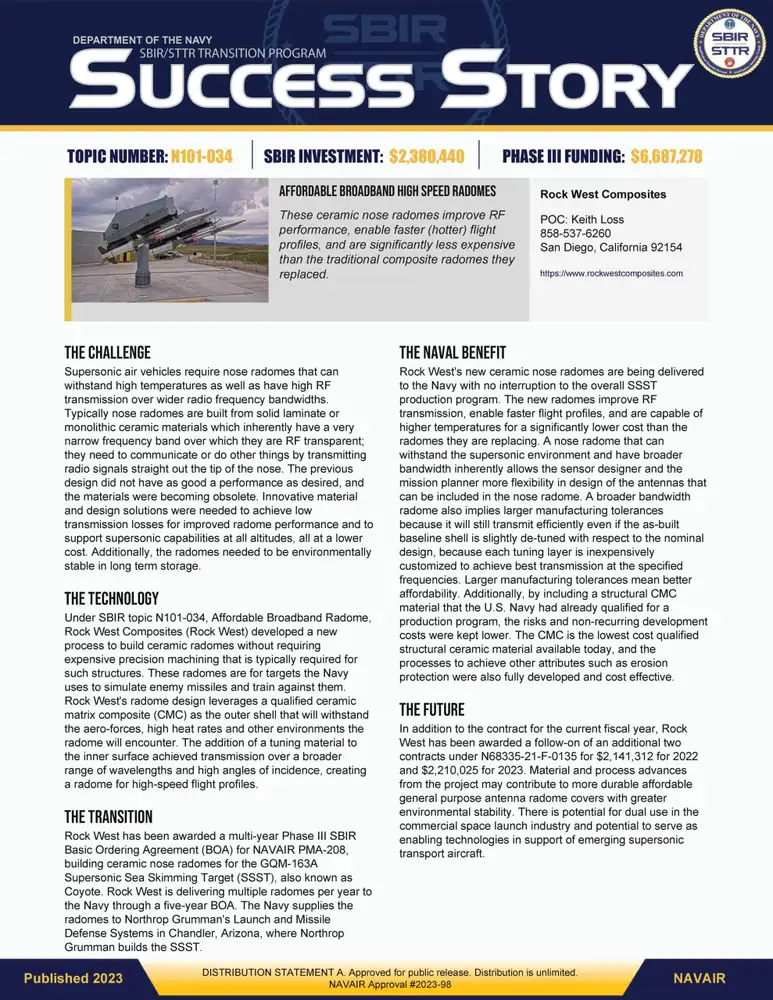

We are proud to support the US Navy through this SBIR program making affordable broadband high-speed radomes. While we’ve talked about this radome program before and even written a case study about it, we’re excited to have been highlighted as a success story by the Department of the Navy’s SBIR/STTR Transition Program office.

We have a total order for 160 radomes to be delivered over four years and are delivering on schedule or earlier.

“The new radomes improve RF transmission, enable faster flight profiles, and are capable of higher temperatures for a significantly lower cost than the radomes they are replacing. A nose radome that can withstand the supersonic environment and have broader bandwidth inherently allows the sensor designer and the mission planner more flexibility in design of the antennas that can be included in the nose radome.”

Read more in the Success Story document below:

Rock West’s best and most important asset is its team of employee-owners. We know that our talented and engaged people are the primary reason why we are able to provide world-class products and services to our customers. We value our team and understand that keeping a healthy environment for everyone matters.

In line with this priority, we are pleased to announce that Cigna has selected Rock West Composites as a recipient of their Silver-level Healthy Workforce Designation for demonstrating a strong commitment to improving the health and well-being of its employees through a workplace wellness program. Rock West’s program focuses on the wellbeing of the whole person, it has leadership buy-in, and it has financial commitment from the company. For example, we engage in activities and challenges around fitness, financial wellness, healthy eating, mindfulness, and career growth, just to name a few.

“We are honored to be recognized with the Cigna Healthy Workforce Designation” said Grace Hernandez, Director of Human Resources. “We understand the important role employee well-being plays in a company’s success and the relationship between healthy employees contributing to a more productive, satisfied workforce and positive business performance.”

As an employee-owned business, the entire team benefits from the enterprise’s success. Investing in an effective workplace well-being program drives value for employee-owners. Senior executives surveyed as part of an Economist Impact study commissioned by Cigna reported greater productivity, stronger staff morale and motivation, and greater retention and loyalty as the most significant business outcomes of a healthy workforce. Additionally, a Gallup Report finds that on average, companies with high employee engagement are 23 percent more profitable.

The Cigna Healthy Workforce Designation evaluates organizations based on the core components of their well-being program, including leadership and culture, program foundations, program execution, and whole person health. Organizations recognized with this designation set the standard of excellence for whole-organization health.

Rock West is proud to offer a healthy and engaging workspace for its people. Join our team if you want to be a part of this terrific group of people!

Reflecting on the Past and Planning for the Future

As we move into our 16th year of business, we are filled with optimism for the future. A business that started as two friends working in a garage has grown to a team of over 200 people in four locations. This growth has been driven by our culture centered around continuous improvement. We always assess past performance to inform how we plan for the future of our business in the world of composites.

People

Our people are our most important asset, which is why we always seek to improve our workplace culture and benefits for Rock West employee-owners. It seems to be working because our San Diego and Salt Lake City locations were named to the 2022 Top Work Places by our local newspapers for the second year in a row! Last year we began building an employee wellness center, which should be completed this year, and our benefits have been expanded based on feedback from our annual survey of benefit preferences. If you want to be a part of a motivated, engaged, and fun group of people, join our team!

Business Markets

Last year we grew revenue over 60%! We made inroads in new markets and reorganized our business development and program management teams around these markets, improving focus on niche requirements and engineering needs as we move forward. You can read more about our Market focus on our recently updated website.

Facilities & Capabilities

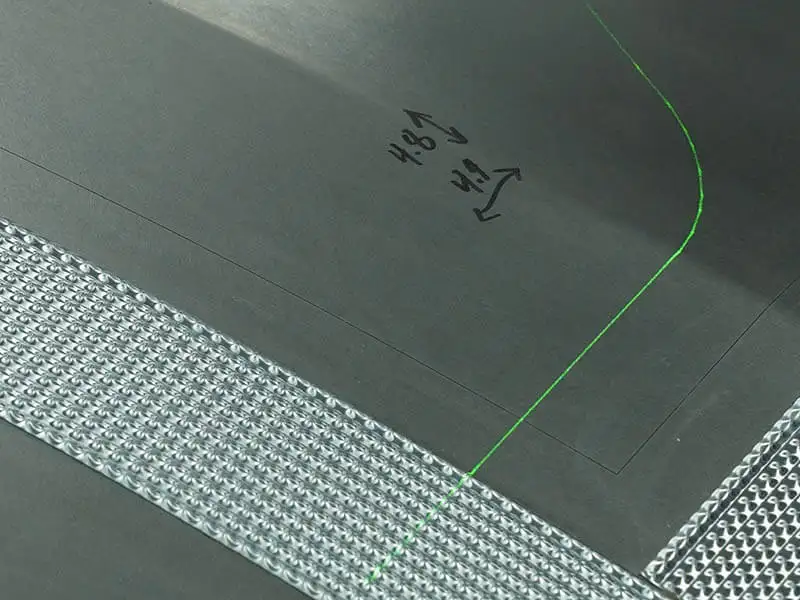

We continue to grow and expand our capabilities. Last year we added an additional 5-axis machine to support the manufacture of larger substrates for space hardware, and we built a custom thermal chamber 50-feet long for thermal cycling long narrow substrates. Also, we added new precision assembly tables, a filament winder, a laser tracker for quality assurance, a laser ply placement system and new software for our CNC ply cutting. This year we’ll be adding a large platen press for oversize plate cures, another 6-spindle filament winder, more precision inspection equipment, and another CNC 3-axis router. We’ll also be expanding our Mexico operations. Our plans are adaptable based on the needs of our customers as we move into 2023.

Laser Ply Placement

Infrastructure

When a company grows this rapidly, its infrastructure has to be updated to keep up with the organization’s needs. This year was an optimal time to upgrade many information systems we use to run our business. We are already noticing the gains of changing to more powerful platforms and anticipate the efficiencies becoming more pronounced as 2023 continues. Saving time and keeping smooth operations helps keep our overhead rates competitive and ensures we continue to provide great value to our customers.

Moving Forward…

We hope your 2022 was wonderful and wish you the happiest of years in 2023! We look forward to working with you!!

Like all of you, our colleagues and customers, we are looking forward to taking time off to celebrate and spend time with our friends and families this holiday season. At Rock West Composites, we take this time to rest and recharge seriously, and as we do every year, we will be closing for a week during the holidays.

Plan Ahead and Order Now!

Do you have projects that need composite supplies during the holidays or at the beginning of the new year? You will be able to order online at any time, but fulfillment will be delayed from when we are closed to when we catch up on back orders in January 2023.

Order now! We will work hard to get your product out the door before the break so you have it when you need it. Due to our holiday closure and a planned system upgrade, there may be additional delays on orders placed after December 22nd.

The Details

Our online store will be open for business 24/7, like always. Our offices will be closed from December 24, 2022 to January 2, 2023. Customer Service will be back at the phones Tuesday, January 3, but order fulfillment will resume later in January.

We take pride in being timely with our shipments, and we appreciate your patience as we start the new year taking care of all your composite needs and also spending some time making our systems work better for you.

The team at Rock West wishes you a safe and happy holiday season!

We are proud to sponsor a new composites forum, the Composites Community. It’s a place to find people interested in composites and talk with experts in the field. You can ask our team and other members of our community about products, technical questions and almost anything related to composites.

It’s easy to register! Go to the Composites Community website and click on the Sign Up button in top right corner. You just need your display name, email and password. Then fill out your profile.

We’ve got videos and experts to answer tough questions. For example, community user Mark had a bike repair he was working on and needed some process information. John Kimball, one of our technical experts helped him evaluate the damage and then let him know what process to follow depending on the amount of delamination that occurred.

Our community is new and will be growing fast. We want to invite you to the neighborhood so you can be a part of that growth and interact with people who love composites as much as you do!

We are proud to announce that both our Salt Lake City and San Diego offices have been named Top Workplaces for the second year in a row. The list is based solely on employee feedback gathered through a third-party survey administered by employee engagement technology partner Energage LLC. The anonymous survey uniquely measures 15 culture drivers that are critical to the success of any organization, including alignment, execution, and connection, just to name a few.

Our San Diego headquarters was named by the San Diego Union Tribune as a Top Workplace, joining a limited 115 local companies with the honor. We placed #49 in the small business category.

Our Salt Lake City office was named by the Salt Lake Tribune as a Top Workplace, joining only 155 companies in the region on the list. We ranked #53 in the small business category.

We take employee satisfaction seriously at Rock West. We conduct quarterly surveys about work satisfaction and annual surveys about benefits. We translate this feedback into concrete action. For example, we’ve incorporated popular employee requests, including switching from a 40-hr work week to a 9/80 work schedule. As an ESOP company, all employees are owners. Being personally invested in the company makes for a highly engaged team. Rock West is rapidly growing, and we are hiring. If you are looking to join an amazing team of employee-owners, apply today!

This week Rock West was happy to host 15 engineering students who are currently taking a composites design class at USCD. We provided a short overview on the manufacturing processes that Rock West performs and then gave a tour of the factory floor. This included taking the students from the freezer, to the kitting room, layup and assembly, curing, machining, paint, and quality inspection.

Afterward we provided some pizza allowing for some informal Q&A time. RWC engineers noted that it was great to interact with the next generation of engineers who asked all sorts of great questions!

copy.jpg)

copy2.jpg)