Virgin Hyperloop made history in early November 2020 when it sent two volunteers barreling down its hyperloop track at 107 miles per hour. The manned test was the first such test of a hyperloop. The company claimed the test was a huge success, but there is still plenty of work to be done before they, or any of their competitors, start carrying cargo and passengers on a regular schedule.

Meanwhile, the hyperloop team at Technical University of Munich (TU Munich) is hard at work building a full-scale prototype of their latest hyperloop system. The team has regularly participated in SpaceX hyperloop competitions in past years, but they have decided to take advantage of the 2020 competition being canceled to move their project to the next level.

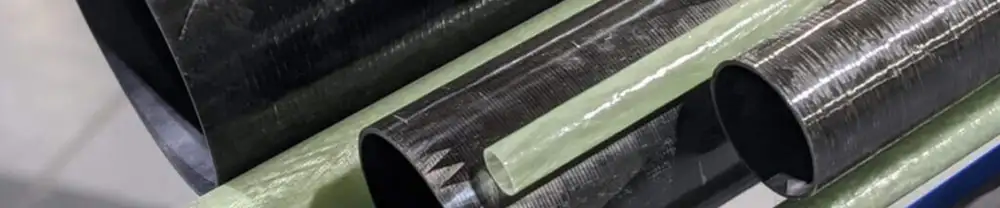

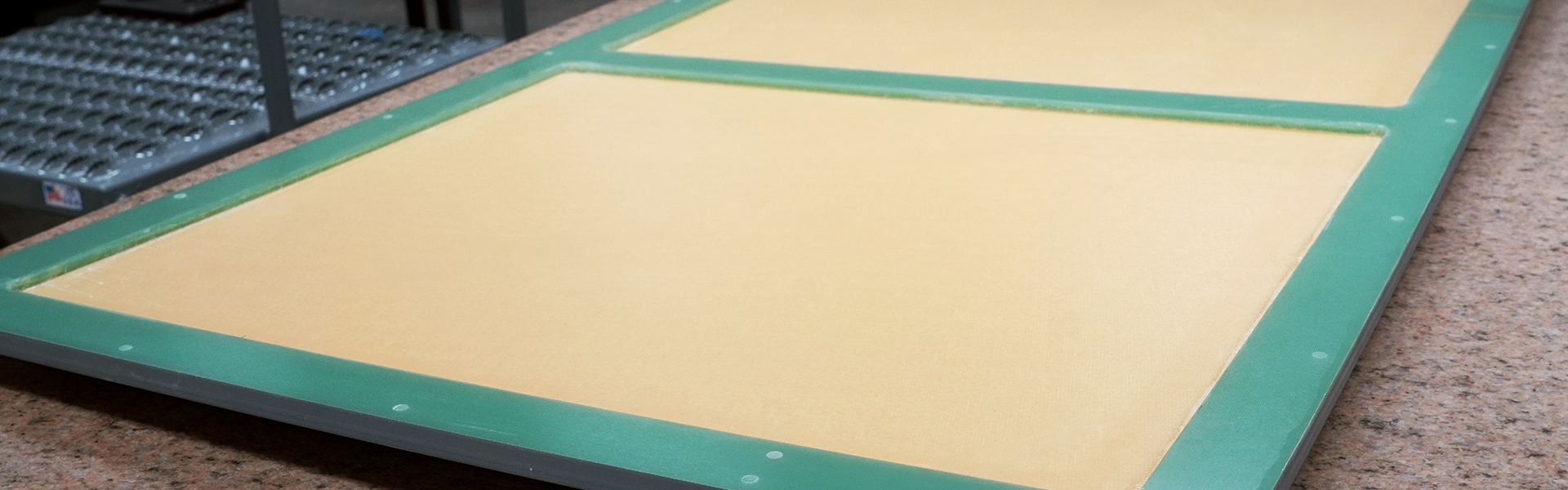

What do we find most interesting about what Version Hyperloop and TU Munich are doing? Their use of composites. Plenty of questions surround the viability of hyperloop technology as the foundation of next gen high-speed transportation. But if it is going to succeed, carbon fiber is going to play a big role.

An Education in Carbon Fiber

The TU Munich team spent many years participating in the SpaceX hyperloop competition with one thing in mind: speed. The goal of the teams is to create a tube and capsule combination that achieves the greatest possible speed while maintaining safety. To go fast – even in a vacuum tube – weight has to be managed.

A CompositesWorld piece from associate editor Hannah Mason describes some of what the TU Munich has gone through in recent years. Mason explained that the team did a lot more than design and build hyperloop pods. They actually had to learn how to use carbon fiber properly.

For example, the team learned that there is very little weight savings in carbon fiber if a given pod’s design doesn’t account for the strengths, weaknesses, and properties of carbon fiber. One of the earlier pods they built weighed in at 11 kg. After analyzing and optimizing it for the next competition, they were able to reduce the weight to 6 kg. All of the weight savings were attributed to “using carbon fiber appropriately.”

Getting It Right the First Time

Another thing the team learned was that it pays to get the design right the first time. Unlike working with aluminum, you cannot make simple adjustments to a carbon fiber part once it is completed. The design engineering has to be rock solid before you start fabrication.

This is not to say that they didn’t build multiple prototypes and adjust their engineering. They did. It is just that they had to go back and fabricate brand-new parts every time an adjustment was necessary. They couldn’t make adjustments by undoing a fastener and sliding a piece of aluminum a little bit further to the left.

Meanwhile, in Nevada

Back in the States, the Virgin Hyperloop team has built a full-scale test track in the Nevada desert. Their recent manned test wasn’t about safety or speed. It was about understanding what it feels like to travel at high speeds in a vacuum tube.

Version Hyperloop uses a ton of carbon fiber in its design, just like TU Munich. Pods are heavy on the carbon fiber to keep their weight down. As for the test track, its design and construction isn’t clear. Could it be one long piece of carbon fiber tubing? It is possible, but not likely.

Whether or not hyperloops ever become reality remains to be seen. But if they do, their construction will be a big boost to our industry. Hyperloops will not be possible without a steady stream of reliable and robust composites.

copy.jpg)

copy.jpg)