As we announced on social media earlier this month, Rock West Composites (RWC) received the CMS Gold Award for Industry from CERN for “excellence in collaborative design finalization and subsequent fabrication of the BTL-Tracker Support Tube Prototype.” The prototype was designed and built for the CMS (Compact Muon Solenoid) detector. Rock West Composites was nominated for the award by Purdue University, with whom we worked on this complex and difficult project.

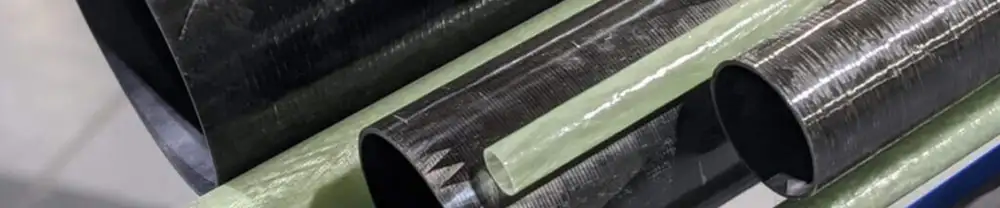

Rock West was one of five companies, and the only US company, to get one of these prestigious awards for 2022. But what’s really interesting is the innovation that enabled this project to meet its objectives. The demonstration tube—2.4 meters in diameter by 1 meter long—had to meet all technical requirements, using tools and processes that were scalable to the future version that will be 5.2 meters long, PLUS remain affordable. The length of the future full-scale tube significantly magnifies the complexity and cost.

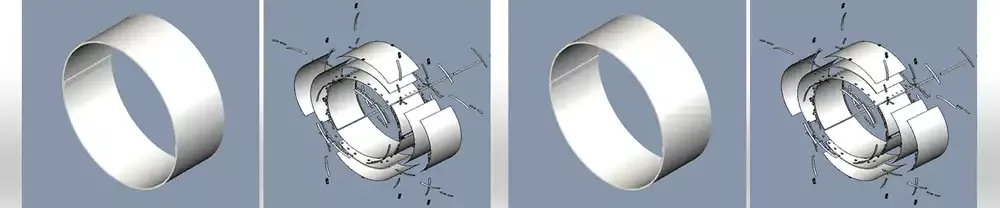

The prototype required collaboration with Purdue University to configure the design for manufacturing. If the composite laminates had been laid up traditionally, the prototype would have been 8 to 20 times more expensive. It would also would have been more challenging to hold an exact diameter since curved composite laminates distort when cured. The solution the Purdue/RWC team devised was to machine the circumferential stiffeners as precision arc segments from a thick laminate of carbon fiber (instead of laying them up on a round mold). This took advantage of the in-plane properties of the laminate, namely, isotropy and low coefficient of thermal expansion (CTE). This avoided the complications due to the high CTE through-thickness. Building in arc segments also allowed for modularity in the manufacturing process, avoiding very large (expensive) tools and easing construction.

Vitruvian Man takes a break. That’s Lee with the final stiffener ring.

Completed Prototype of the BTL-Tracker Support Tube

The BTL Tracker Support Tube prototype appeared as a simple cylinder from the outside, but it had multiple circumferential stiffeners, 100s of inserts, extremely stiff rails for instrument loading, and lengthwise splice plates. It met all CTE, stiffness and dimensional tolerances- as well as budget and schedule. RWC’s Director of Product Development, John Marks, worked closely along with team at Purdue University, Dr. Andreas Jung and Dr. Ben Denos. RWC collaborated with Purdue to have them do the tool design which saved budget and helped Purdue fund its team. Our RWC technicians, including Chad Williams, Lee Bridges, and Jose San Vincente, skillfully executed the prototype.

Rock West Team with the arc tool.

“Starting in 2000, the CMS Collaboration has honored industrial companies that have made outstanding contributions to the construction of the experiment with the CMS Gold Award. Companies who have demonstrated their excellence and engagement and who provide parts within specifications and on schedule are considered for this award.” – CERN/CMS

We are particularly proud of this award not only because of the technical challenges this program presented, but because of our successful collaboration with the team at Purdue. Thanks to the Purdue team for the nomination and for all our colleagues who helped make this program succeed!

copy.jpg)

copy.jpg)