Have you ever spent time in a natural history museum gazing at the skeleton of a dinosaur? And if so, did you ever stop to consider whether or not the bones of that skeleton were real? We hate to burst your bubble, but it is highly likely that not all of the bones were genuine. In fact, the entire skeleton could have been made from glass or carbon fiber.

Apparently, scientists need only about half the original bones from a dinosaur skeleton to create a complete replica. Furthermore, it is extremely rare for paleontologists to recover 100% of the bones of a particular skeleton. So most museum displays contain at least some fabricated bones.

From Plaster of Paris to Carbon Fiber

Having to deal with missing bones is not a modern phenomenon. As far back as the 1800s, scientists realized they needed to fabricate replacement bones in order to complete the fossil record. The go-to material way back then was plaster of Paris. It worked well enough for the day, but its obvious shortcomings soon had scientists looking for a new material.

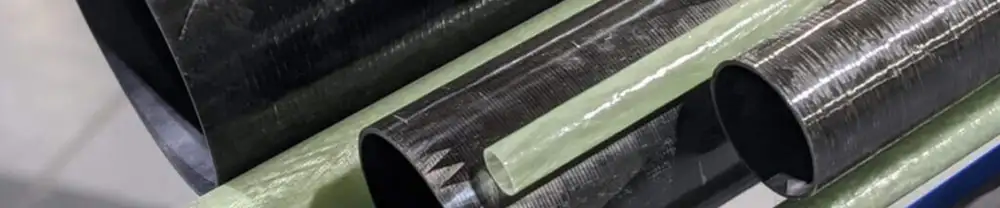

Plaster of Paris eventually gave way to urethane foam and then plastics. But these days, museums are less likely to fashion their own bones from foam and plastic. Instead, they turn to composites fabricators who make the bones from glass fiber or carbon fiber composites.

Urethane foam works well enough for small bones that do not span large distances. It is not a good choice for larger bones because it lacks the necessary density. Solid core plastics are better for large bones, but the resulting pieces can be too heavy to safely suspend within a dinosaur model.

Glass and carbon fiber are better choices because they are easily molded into hollow pieces. Fabricating dinosaur bones with glass and carbon fiber is so effective that there are now companies that specialize in that very thing.

Off-The-Shelf Dinosaurs

A recent CompositesWorld article exploring composite dinosaur bones referenced one particular company that operates a 60,000 square foot facility in Ontario, Canada. The company possesses somewhere between 15,000 and 20,000 molds pertaining to some 270 dinosaur skeletons.

This company can produce just about any dinosaur bone a museum or theme park could want. Better yet, they also provide complete, off-the-shelf dinosaurs on demand. They can even install the skeletons if necessary.

The CompositesWorld piece says there are fewer than 30 genuine T-Rex skeletons in the world. Yet hundreds of museums and theme parks have them. How is that possible? Most of the skeletons consist of 100% composite bones. Nothing about them is real.

Virtually Endless Possibilities

Here at Rock West Composites, we get a big kick out of reading stories like these. It reminds us of the virtually endless possibilities composites bring to the table. If you can dream it up, someone can probably build it out of fiberglass or carbon fiber. Both materials are just that versatile.

We normally think of carbon fiber as a material for sporting goods, automobiles, boats, and planes. It certainly meets the needs of manufacturers in all sorts of industries. Yet not many people consider the fact that the skeletons they might be seeing at the local museum are made of carbon fiber as well.

Glass and carbon fiber offer a lightweight but durable manufacturing option for all sorts of applications. Both materials are exceptionally strong. They are easy to work with and they will not rust. As such, a glass or carbon fiber dinosaur skeleton should have a lifespan of at least a few hundred years. That is pretty impressive by any standard.

copy.jpg)

copy.jpg)