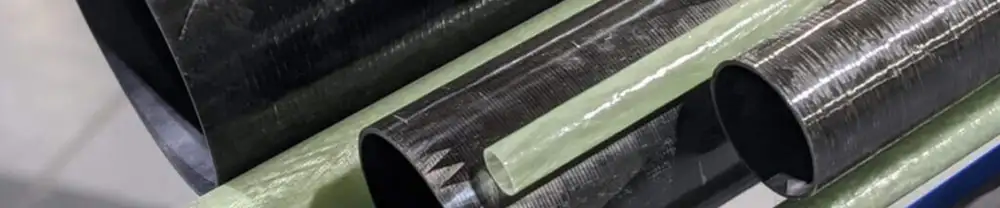

As a leading provider of composite materials in Salt Lake City, we frequently sell products to home fabricators. This includes glass and carbon fiber fabrics, tubes, plates, epoxy resins, and even adhesives. Working with any of these materials does pose some amount of risk to human health. As such, we recommend our home fabricating customers be smart about using personal protective equipment (PPE).

The pros use appropriate PPE whenever working with carbon or glass fiber. We use PPE at all of our facilities. If you are a home fabricator, you should too. Do not take any chances with your health. There is no valid reason to risk injury when a few pieces of PPE will keep you safe. We recommend the following four types of PPE:

4 Pieces Of PPE For Carbon Fiber And Fiberglass Home Fabricating

1. Protective Clothing

At the top of the list is protective clothing that will keep both carbon and glass fibers from contacting the skin. The fibers can be irritating to the skin even among people who don’t normally have reactions to potentially irritating materials. Why? Because both glass and carbon fibers are extremely small. If they get stuck to the skin, they can irritate pretty easily.

Protective clothing should include long pants and a long-sleeved shirt. A hat and work boots are also advised. After working with glass or carbon fiber, your protective clothing should be washed. Do not hang it up dirty and reuse it later as you run the risk of transferring fibers stuck on the clothing onto your skin.

2. Nitrile and Work Gloves

Next, we recommend two different types of gloves. During the fabrication stage, use nitrile gloves to prevent contact with epoxy resin and loose carbon and glass fibers. Nitrile gloves do the job and are very inexpensive. Best of all, they are disposable. That means you do not have to try to clean your gloves after handling epoxy.

Post fabrication, we recommend a pair of heavy-duty work gloves to protect your hands during grinding, cutting, sanding, etc. The purpose here is to protect your hands against any splinters that may result from machining finished parts.

3. Eye Protection

It is absolutely imperative to protect your eyes whenever you are working with composite materials. During the fabrication stage, you don’t want glass or carbon fibers in the air to make contact with your eyes. You do not want epoxy to accidentally splash up into your face either. During machining process, eye protection keeps you safe from carbon fiber dust and splinters. In both cases, safety glasses are the bare minimum.

4. Face Masks

Finally, it is wise to protect your respiratory system by wearing a face mask. A mask reduces the risk of exposure to small carbon fibers and carbon fiber dust. A filtered mask can protect you against the sometimes-overwhelming fumes put off by epoxy resins.

In addition to a mask, it’s advisable that you fabricate with carbon and glass fiber in well ventilated areas. Ventilation allows for faster dispersal of annoying fumes. With good ventilation, you will breathe easier and have a lower risk of being overcome.

One last thing we advise: familiarize yourself with appropriate first aid. For example, it’s best to treat skin irritation and rashes by washing the affected skin with soap and warm water to remove fibers. There is no need to scrub, and you probably shouldn’t if your skin is already irritated.

We applaud your desire to fabricate with glass and carbon fiber at home. Both materials offer a tremendous number of applications for home fabricators. Just do yourself a favor and be safe. Wear the appropriate PPE whenever you are working on composite projects.

copy.jpg)

copy.jpg)