We sell carbon fiber tubing to DIY hobbyists and commercial users alike. And while we offer to cut tubes to specific lengths, we get the fact that customers sometimes have to cut tubes themselves. This post is intended to give you a starting point for cutting tubing in your own shop.

Please note that machining carbon fiber products does take practice. Whether you are cutting, drilling, sanding, etc. it may take you several attempts to get it right. You might want to practice on scrap pieces before attempting to machine parts that will be used in finished products.

Carbon Reinforced Plastic

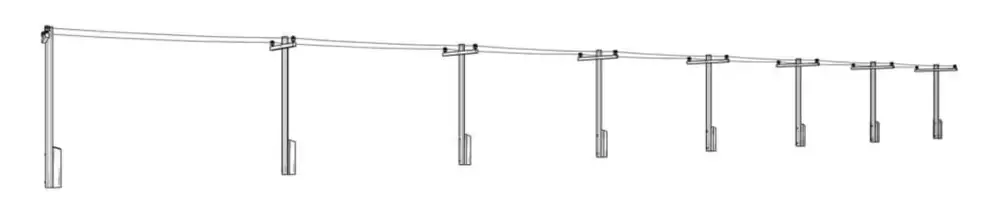

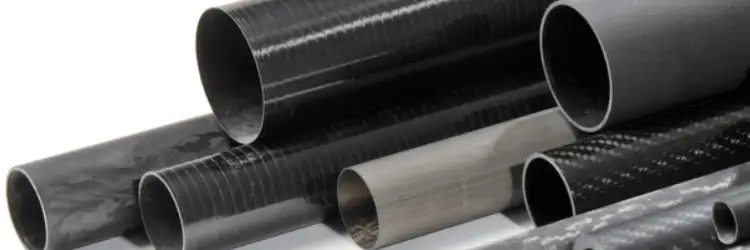

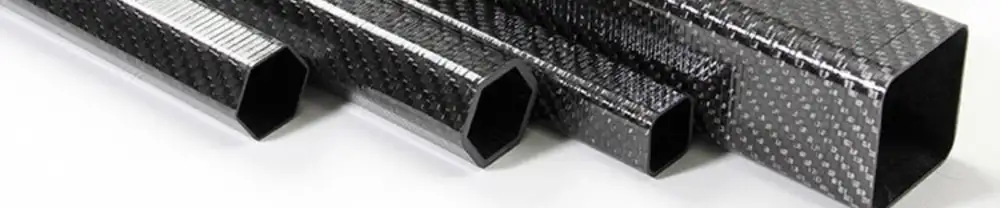

The first thing to understand is what carbon fiber tubing actually is. A finished tubing product you purchase from us is essentially a carbon fiber plastic. The plastic component is an epoxy resin that has been cured. Carbon fiber embedded in the plastic provides reinforcement. Why does this matter?

Cutting carbon fiber tubes generates heat. Larger, denser tubes can generate enough heat to reactivate the epoxy resin. The end result is a slight melting of the plastic material that can gum up your saw. The best way to avoid this is to choose the right saw blade. You can also use a machining liquid to keep the saw blade cool.

Choose Your Blade Wisely

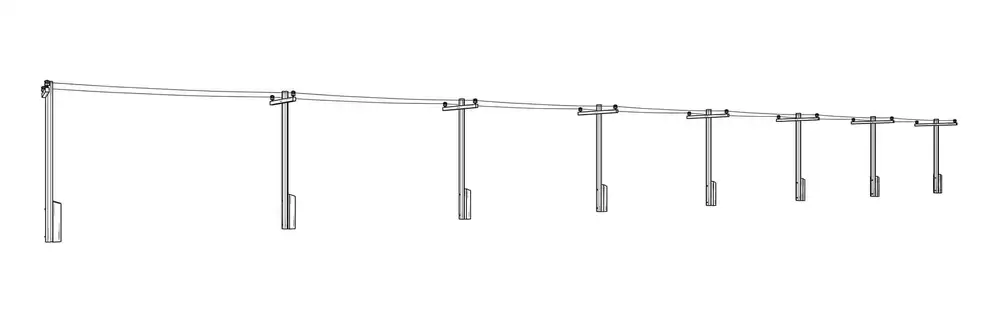

Fibers embedded within a piece of carbon tubing are still fibrous in nature. They haven’t been altered by combining them with the epoxy. As such, your choice of saw blades is important. We recommend staying away from a toothed blade. Why? Because fibers can get caught on teeth. This could result in significant delamination which, ultimately, compromises the integrity of the tube. Splintering is also fairly common.

Instead, a diamond coated abrasive cut-off blade is your best bet. A segmented blade will also work, and it will not generate as much heat. Regardless of the blade you choose, pay attention to its wear. The more worn your blade, the less clean your cut.

As you cut, let the blade do the work. Go as slow as necessary to prevent forcing the blade through the material. A slow and steady approach will ensure a clean cut with very little risk of delamination. On the other hand, forcing the blade through could damage the tube to the point of making it unusable.

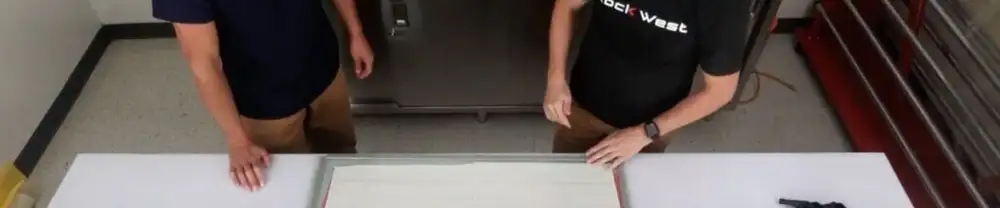

Secure the Tube Properly

Many a cutting job has gone awry because the fabricator did not properly secure the tube in question. It is important that you limit movement as much as possible. If tubes move even a slight amount, you will not get a clean cut. If they move too much, you risk delamination and burring.

We suggest bracing the tube against a hard edge and holding it in place with a series of clamps. If you are cutting off a small piece, no additional clamps are necessary. However, consider how you secure the tube if you’re cutting a long piece into two even sections. It would be wise to secure and clamp both ends to ensure a clean cut.

Cleaning Up

Even the best fabricators do not get a perfectly clean cut every time. Sometimes you’re left with burrs or an unusually rough edge. Not to worry. You can clean up with medium grit sandpaper using a grinder or spinning the tube on a lathe.

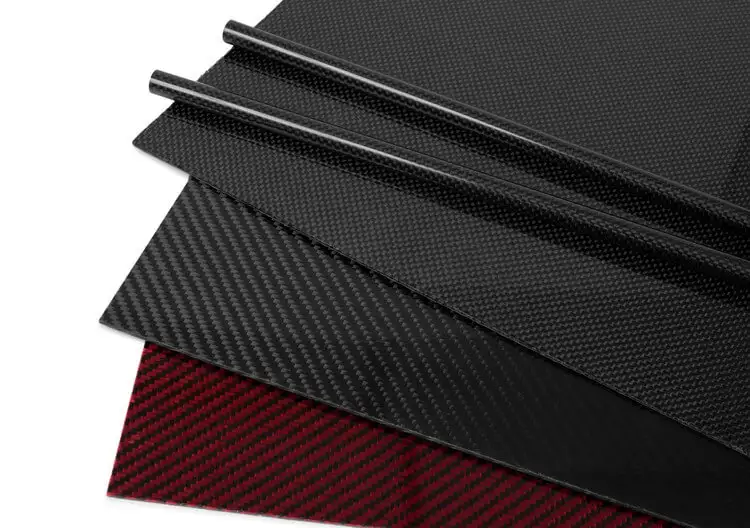

We carry a variety of carbon fiber tubing products in different shapes and sizes. Contact us to learn more about our unidirectional and multidirectional tubes suitable for commercial and home use. We would be happy to explain the benefits of carbon fiber over steel, aluminum, and titanium.