FOR IMMEDIATE RELEASE

Rock West Composites Is Expanding Its Short Lead Time, Space-Ready STRATO™ Product Line

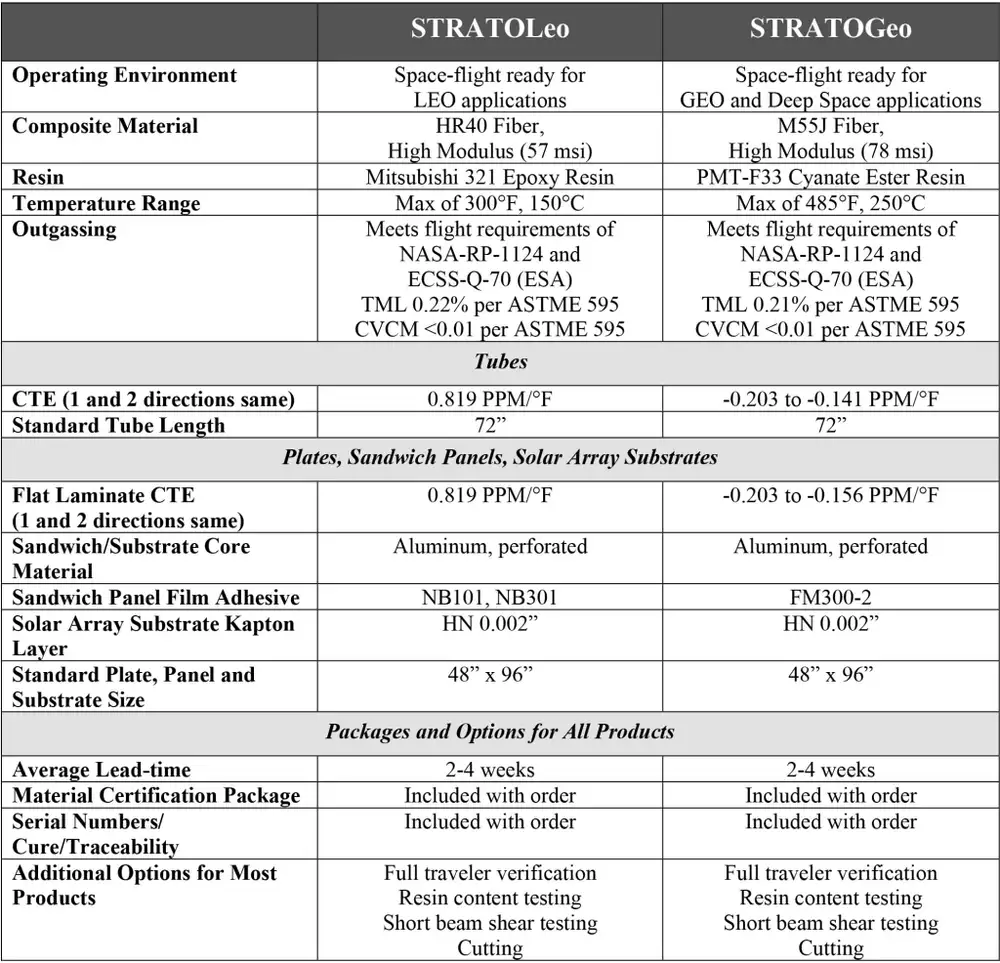

This month Rock West Composites announces the expansion of its space-grade STRATO product line, which now has two classes created for LEO, GEO and Deep Space applications. These selections of tubes, plates, sandwich panels, and solar array substrates are some of the Space market’s fastest turnaround products with most lead times ranging from two to four weeks.

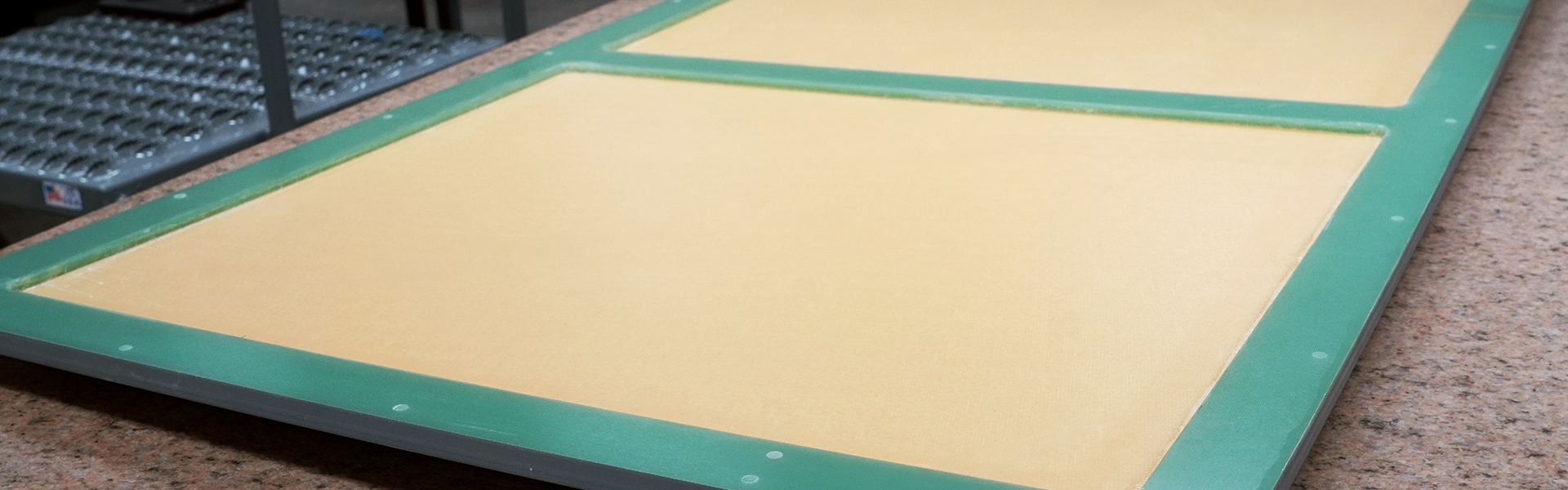

San Diego, CA (PRWEB) April 11, 2023 – Rock West Composites (RWC) announces the expansion of its STRATO space-grade product line this month. Originally focused on tubes for Lower Earth Orbit (LEO) applications, a secondary line will now include products appropriate for Geosynchronous Equatorial Orbit (GEO) and Deep Space use. STRATO products now include plates, sandwich panels, and solar array substrates for both orbital types.

The STRATO line is designed to provide businesses and government agencies high-quality components commonly needed for spacecraft, but RWC offers dramatically shorter lead times—approximately two to four weeks—than competing providers, and the order can be placed easily online.

The entire STRATO line meets key requirements for space, with properties that include low outgassing, low to zero CTE, high modulus materials, and a wide operational temperature range. RWC can offer significantly reduced lead times because it stocks raw materials such as M55J/PMT-F33 Cyanate Ester and HR40/NB321 Epoxy for its ecommerce business.

The STRATOLeo class is a more cost competitive option for meeting space requirements without the additional high-performance capability typically associated with GEO orbits and Deep Space flights. The STRATOGeo class uses top-of-the-line materials in all cases where performance can’t be compromised. The table below details some of the differences of the product classes.

Each order includes a certificate package with dimensional inspection, material certificates, traceability, and a certificate of conformance from RWC. All products are serialized and traceable. Additional options for some products include full traveler verification, resin content testing, and short beam shear testing.

“Our goal is to make space quality hardware readily available in a cost effective and efficient manner,” said Jeremy Senne, head of RWC’s Space market segment. “Whether it’s a start-up business building cube sats or large prime contractors looking to optimize operations, agile organizations in a rapidly growing industry need high quality solutions quickly. Our hope is to help minimize design and build timelines by standardizing available products.”

For more information on RWC’s STRATO line, visit www.rockwestcomposites.com/strato.

About Rock West Composites

Rock West Composites provides composite products for a variety of markets and customers. Specializing in carbon fiber composites, RWC offers custom products and solutions, such as product development, engineering services, prototyping, and manufacturing, as well as off-the-shelf products, including tubes, plates, complementary materials, and their space-ready STRATO line. Manufacturing processes include filament winding, roll wrap, resin infusion, bladder molding, modified closed mold, compression molding, autoclave cure, and precision assembly processes. Rock West Composites has facilities in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

copy.jpg)

copy.jpg)