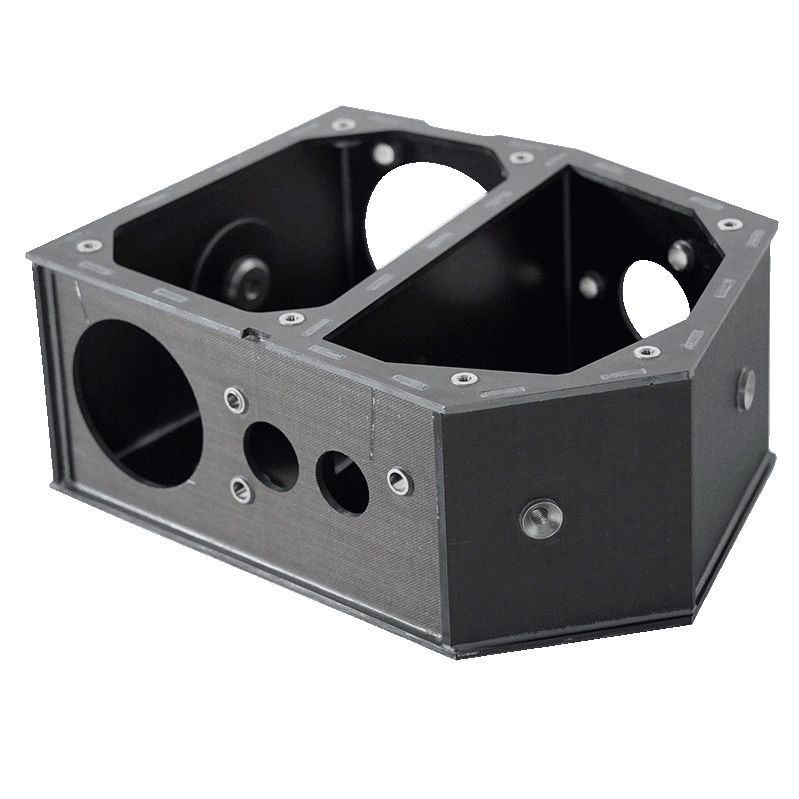

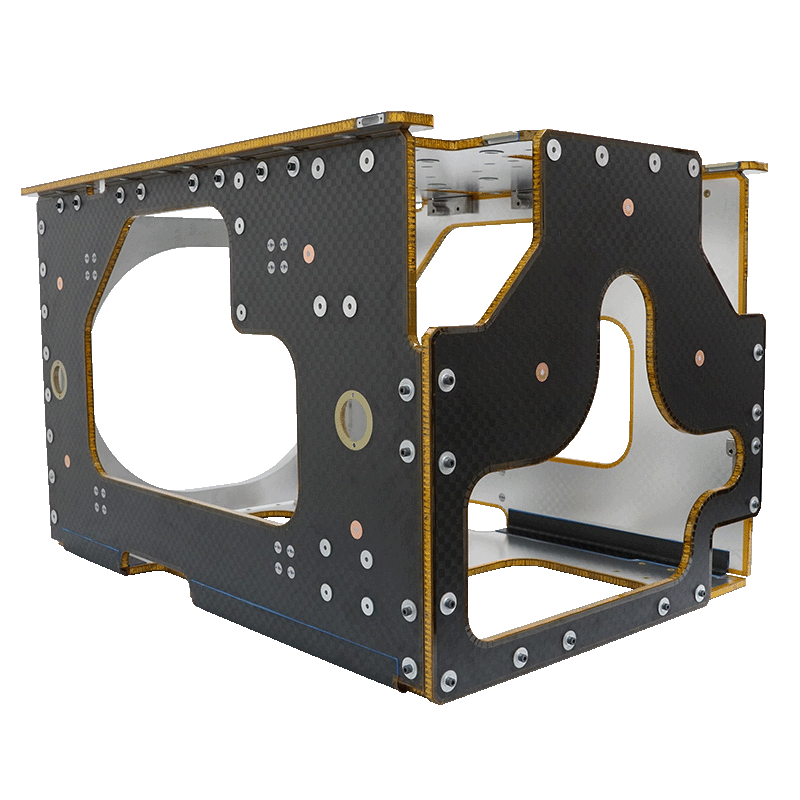

Composites Structures for Space Applications

OUR SPECIALTY: Optimizing materials for the exacting requirements of extreme environments

THE BENEFIT TO YOU: We maximize efficiencies in qualification and production to meet and exceed your requirements

OUR BUSINESS: Customer-focused, employee-owned, agile

THE TEAM: In-depth and broad range of experience in composites for space applications

In-house Testing

STRUCTURAL:

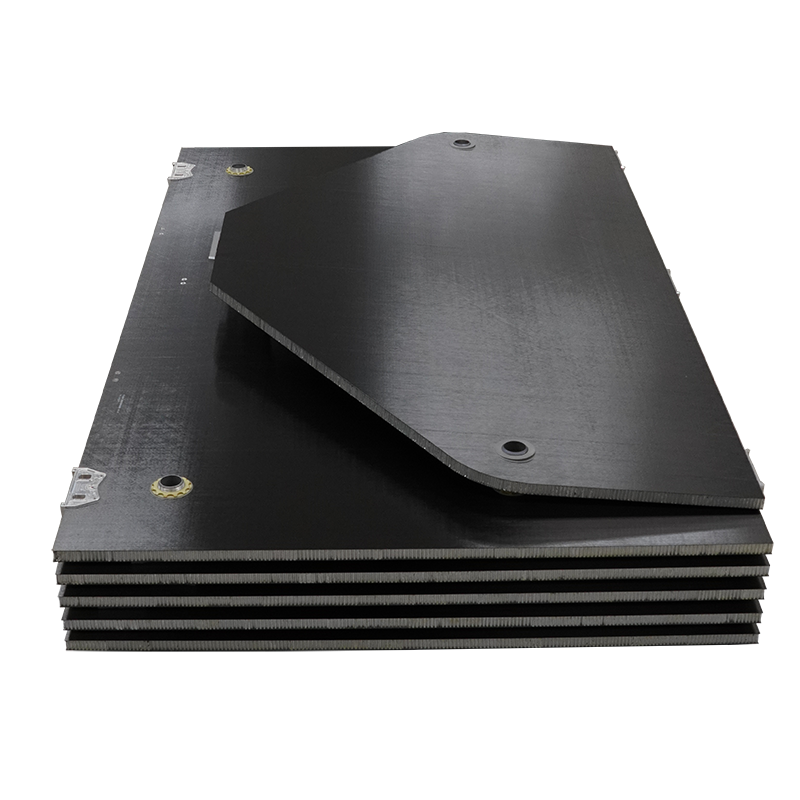

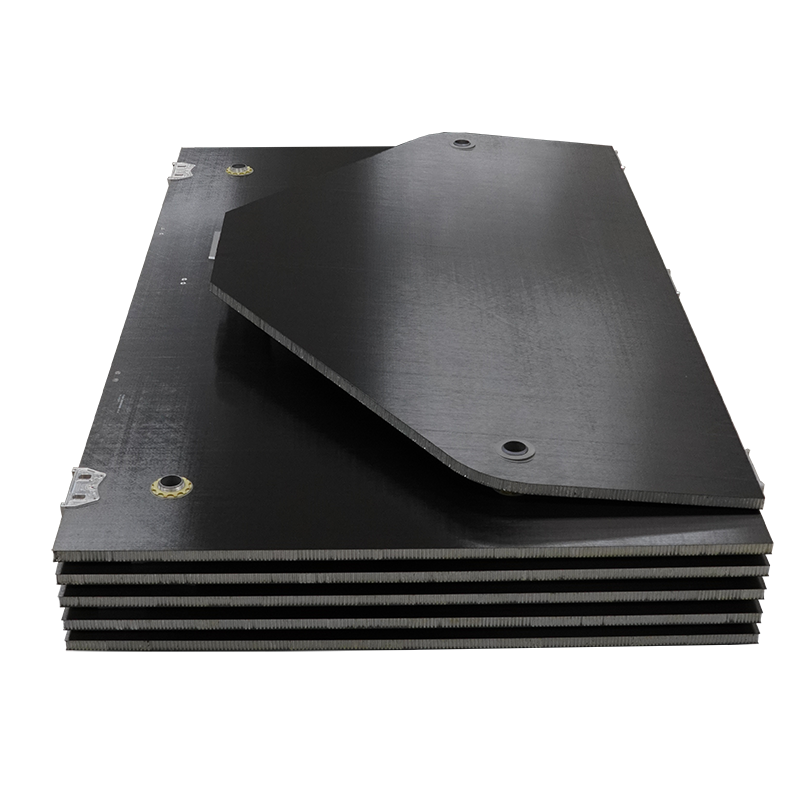

Our team has brought a range of finished part structural testing in-house to ensure the full program can happen under one roof. Testing ranges from panel insert pull testing to multi-axis high load structural testing on panel assemblies and strut assemblies.

COUPONS:

We have brought a suite of ASTM coupon testing in house to support both characterization of new materials as well programmatic work-in-progress (WIP) testing to verify final deliverables have been processed properly to all specifications.

THERMAL CYCLING:

Rock West has capabilities to thermal cycle a wide range of coupons and hardware from -180°C to +180°C with chambers ranging from 2’x2’x2’ to 10’x8’x9’ to 3’x3’x50’