It was only a couple of years ago that SpaceX founder Elon Musk unveiled an all-carbon-fiber rocket body for his interstellar spaceship to Mars. Then, seemingly without warning, Musk pulled the plug on the project. He scrapped the carbon-fiber rocket body, closed the Port of LA fabricating facility, and walked away from a lease on land he intended for a full-scale production facility.

Those who follow Musk and his SpaceX exploits were shocked. They had heard for years that carbon fiber was the key to making Mars colonization possible. Learning that he was scrapping carbon fiber in favor of stainless steel was puzzling, to say the least. Well, now we know what happened. We finally know why SpaceX abandoned carbon fiber.

We Now Know Why SpaceX Abandoned Carbon Fiber

A Massive Transport Project

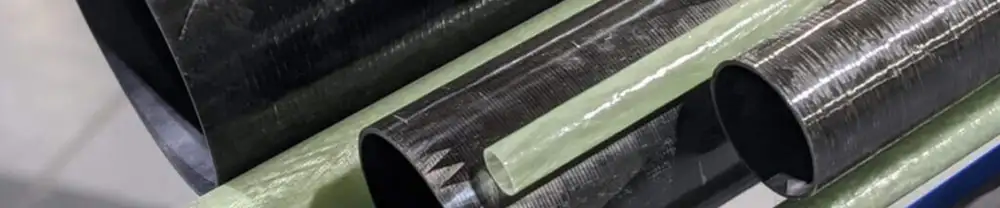

Carbon fiber was the material of choice when SpaceX first began designing its Starship (formerly BFR) rockets. The reason was simple enough: carbon fiber’s impressive strength-to-weight ratio makes it superior to steel and aluminum for massive spaceships carrying unimaginable volumes of cargo.

Understand that a single trip to Mars will take years. The first waves of colonists will not be able to rely on regular supply deliveries similar to that which the International Space Station receives. They will have to take everything they need with them. Practically speaking, you are talking massive ships carrying everything from food to medical supplies and construction materials.

Musk determined that stainless steel would be impractical for building such large ships. Carbon fiber gave him a license to think as big as he wanted. But after a few years of research, building, and testing, he finally reached the conclusion that carbon fiber was not the way to go after all.

Two Big Concerns

Carbon fiber proved to be everything SpaceX thought it would be. However, there were too big concerns. The first is temperature resistance. While carbon fiber stands up extremely well to temperature extremes here on planet Earth, it wouldn’t do so well during atmospheric reentry. It just doesn’t stand up to that much heat.

In order to make carbon fiber work for a reusable rocket, the entire body would have to be insulated. That is certainly possible to do, but it adds to the expense. It also adds to the weight. A stainless-steel rocket body would only have to be insulated on the windward half. The rest of the body would be just fine. Why? Because stainless steel is much more temperature resistant.

The other concern was cost. SpaceX determined that it would spend upwards of $130,000 per ton to use carbon fiber as the primary rocket body material. On the other hand, it would spend just $2,500 per ton for stainless steel. It doesn’t take a mathematician to figure out that spending 50 times as much on carbon fiber would put considerable strain on the Starship project.

A Long Way Off

Musk and SpaceX are now in the process of trying to re-establish production facilities at the Port of LA. Rumor has it they want to begin manufacturing stainless steel rocket bodies and other parts from that location before shipping them across the United States to other facilities. In the end, however, a viable Mars spaceship is still a long way off.

Who knows what SpaceX will learn between now and the day it is ready to launch its first prototype? By then, the cost of carbon fiber materials will likely have dropped significantly. Perhaps improvements in manufacturing technologies will have made carbon fiber as heat-resistant steel. Who knows? SpaceX could eventually scrap stainless steel and go back to carbon fiber again.

copy.jpg)

copy.jpg)