One of the most exciting aspects of working in the composites industry is developing new composite materials through science. That is how we came up with carbon fiber decades ago. Scientific experimentation with different materials has brought us everything from glass fiber to Kevlar.

Now there is a new kid on the block, a kid our industry is pretty excited about. That kid is the carbon nanotube, and it represents one of the building blocks of a new breed of composites combining carbon molecules with natural fibers and epoxy resin.

A project now being developed at the University of Johannesburg in South Africa has led to a new composite material that combines epoxy, carbon nanotubes, and plantain fibers. Researchers still have work to do before their composite is marketable, but they have achieved impressive results thus far.

Composites Are Better Materials

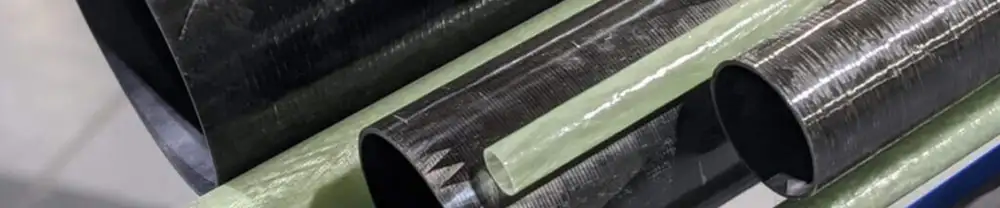

For the record, composite materials are better materials due to the properties of the components of which they are made. Your typical carbon fiber reinforced plastic (CFRP) is a classic example. Making a CFRP involves combining carbon fibers with epoxy resin via spinning, braiding, or manual layups.

Both components offer attractive properties on their own. Combine the two and you have a much better material that draws on the strengths of each component. That is how composites work. Composite materials possess properties that its individual components do not possess separately.

With that in mind, fibers taken from plantain stems have some very desirable properties for manufacturing. But those fibers are of very little value on their own. Use them to reinforce an epoxy resin in the same way carbon fibers are used, and you now have a new material you can do something with. But why stop there?

Researchers at the University of Johannesburg figured out they could make an even better material by adding carbon nanotubes to the mix. They were right. Carbon nanotubes made their composite material stronger, more rigid, and more heat resistant.

More About Carbon Nanotubes

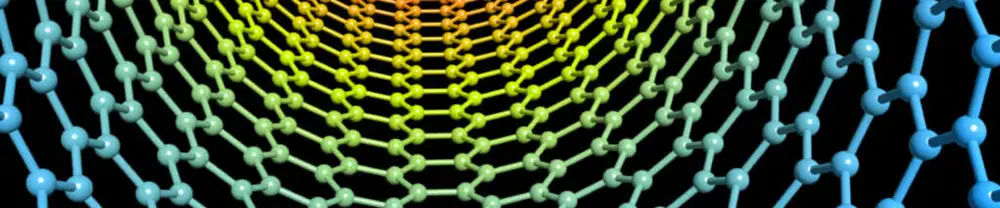

We do not talk much about carbon nanotubes on our blog because they don’t yet enjoy widespread use in our industry. Yet it is safe to say that they are up-and-coming. Carbon nanotubes can be used in ways that carbon fibers cannot. And when combined with other materials in just the right formulas, they yield pretty impressive results.

A carbon nanotube is a molecular structure comprised of multiple carbon atoms arranged in a cylindrical structure with hexagonal covalent bonds. For illustrative purposes, imagine taking a piece of chicken wire and rolling it into a cylinder. That’s what a carbon nanotube looks like – but on a molecular scale.

Carbon nanotubes can be both single- and multi-walled. The South African researchers chose multi-walled nanotubes and added them to their formula at a ratio of 1% by weight. The result was a composite that was stronger and yet still moderately flexible.

Molding Car Parts

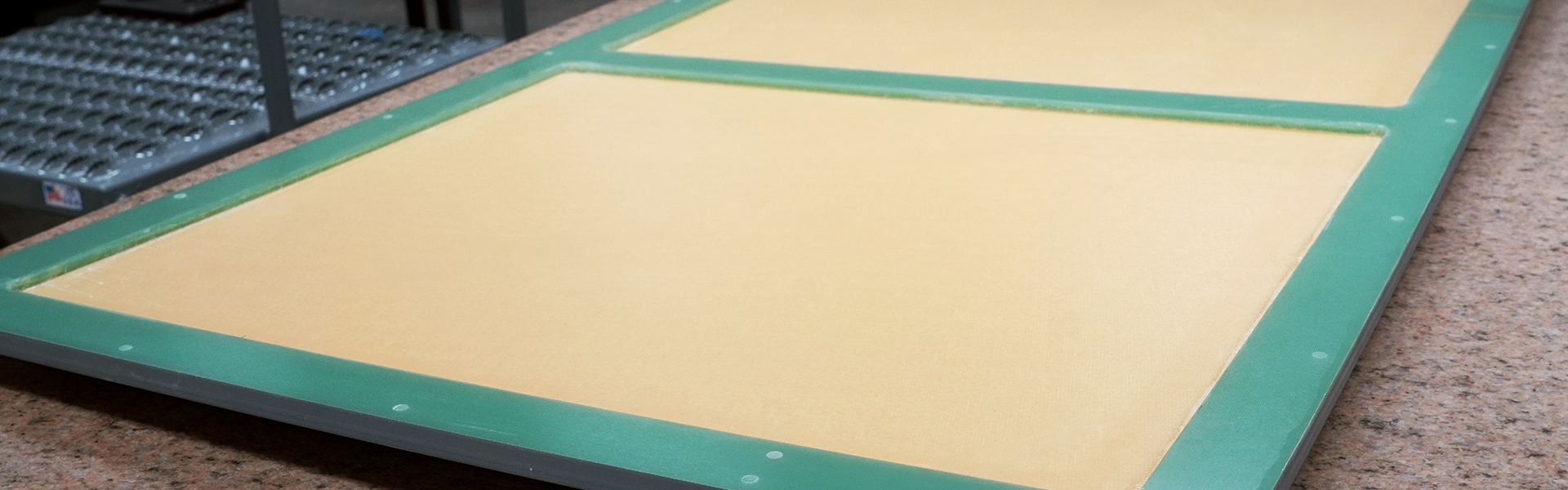

The proverbial icing on the cake is the fact that the resulting plantain fiber composite is easily molded at room temperature via pressure. Researchers were able to fabricate parts in 24 hours, but only after treating the natural fibers and combining them with resin and carbon nanotubes.

Their technology isn’t quite ready to produce the types of composite parts necessary for high-performance applications, but it is capable of cost-effectively producing composite parts that do not require maximum tensile strength. This suggests cheaper composite parts for things like car interiors and/or insulation panels.

What do you get when you combine plantains with carbon fiber nanotubes? A new natural composite with exciting possibilities for the auto industry.

copy.jpg)

copy.jpg)