Most of the customers who purchase carbon fiber materials from Rock West Composites are pros. They use what they buy from us to fabricate individual parts and finished products they intend to sell to their own customers. But believe it or not, some of our customers are DIY fabricators. Yes, DIY fabrication is entirely possible.

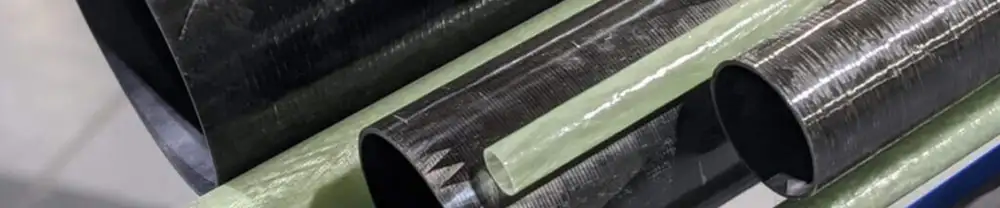

It is true that carbon fiber and similar composites are complex materials with a lot of science behind them. But you don’t have to go through the expensive and labor-intensive process of creating carbon fiber for your own layouts. You can buy carbon fiber sheets and prepregs from us. Rock West and our suppliers have done all the hard work for you. You take what you purchase from us and do the layup process at home.

If you are interested in learning more about DIY fabrication, there are great videos all over the internet. We found one series demonstrating how to make carbon fiber-reinforced propellers for drones. The fabricator who produced the videos started with a foam core that he then reinforced with carbon fiber sheets to create some pretty impressive props.

1. BUILD YOUR TOOL

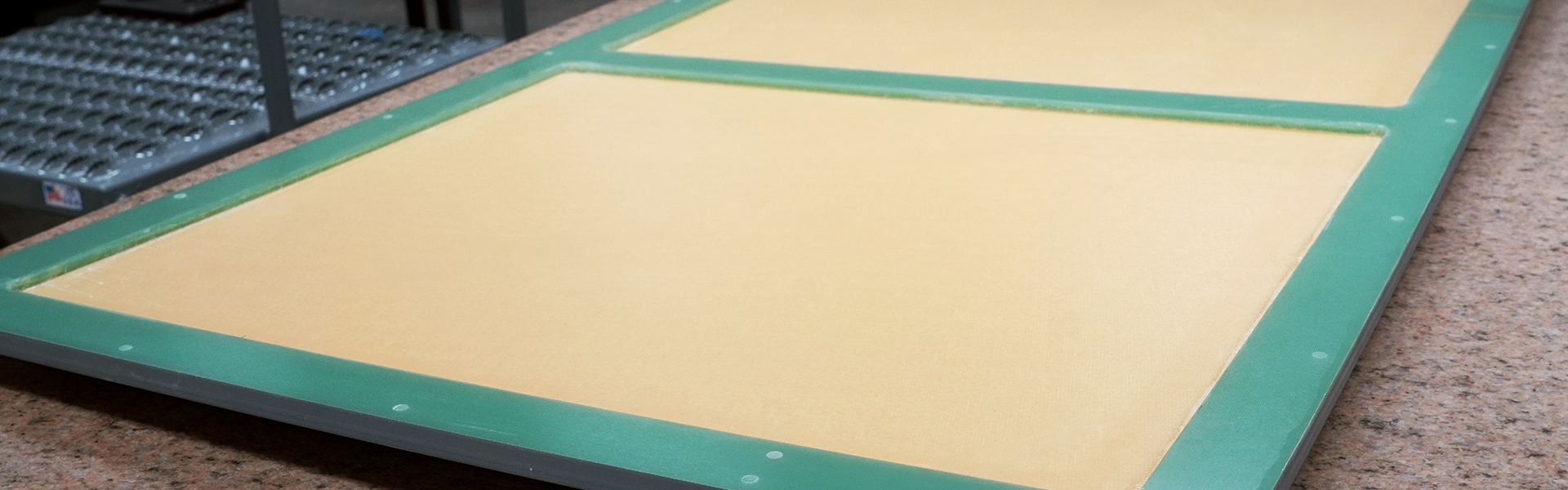

The first step in DIY fabrication is to build your tool. In the composites world, a tool is a mold. You can build a tool in one of two ways. The first is to make a traditional mold into which you will place carbon fiber sheets in multiple layers. Once cured, you remove the part from the mold.

Carbon fiber propellers for a quadcopter drone.

The other option is to do what the drone prop fabricator did. He created a tool that acted as both the mold for his layup and the core of the finished product. Rather than laying carbon fiber sheets into his tool, he wrapped the tool with the sheets. He was left with one solid piece after curing.

2. PREPARE THE CARBON FIBER SHEETS

The next step is to prepare the carbon fiber sheets by cutting them to size and impregnating them with epoxy resin. Note that you don’t need to impregnate if you’re using prepregs. Prepreg sheets are already impregnated with epoxy.

Cutting carbon fiber to size does take some practice. One of the things the fabricator in the drone prop video does is mark his cut lines and then apply cellophane tape on either side before cutting. That way, when he does eventually cut the material, the raw edges on either side of the cut do not start to unravel. It’s little tricks like this you learn as you go.

Carbon Fiber Drone Propellers

Carbon Fiber Drone Propellers

3. LAYUP THE MATERIAL

Step number three is to layup the carbon fiber material in or over your tool. With each layer, you are going to apply additional epoxy resin to make sure the entire surface of each sheet is impregnated. A lot of DIY fabricators use a steel roller to firmly press the layers into place and simultaneously remove air. To reduce the amount of air bubbles or “voids”, it’s also a good idea to vacuum bag your layup to remove air during cure.

The number of layers necessary to complete your layup depends on the design of your part. Some parts call for more layers than others. At any rate, the final step is to place your mold in an insulated environment and apply some heat. Typical epoxies cure at about 250F, but there are also room temperature-cure epoxies available that just require a bit more time to fully cure.

What we’ve described here constitutes the basics of DIY carbon fiber fabrication. Obviously, there’s more to it as parts get more complicated. The point here was just to let you know that DIY carbon fiber fabrication is possible.

copy.jpg)

copy.jpg)