The U.S. Department of Energy (DOE) has awarded some $2.7 million to the Institute for Advanced Composites Manufacturing Innovation (IACMI) for the purposes of developing new composite fuel tanks made mostly of carbon fiber. The fuel tanks themselves are nothing new, and manufacturers have been making them for quite some time. So why is the government spending so much money on this project?

The DOE’s goal is to cut the cost of manufacturing high-performance carbon fiber by up to 25%. With that kind of savings, it would be easier to justify manufacturing the majority of hydrogen and natural gas tanks from virgin carbon fiber. And that is important for a number of reasons, beginning with the need for an alternative to both electricity and gasoline/diesel for transportation.

An Alternative to Electric Cars

Our national desire to replace gasoline- and diesel-powered vehicles with all-electrics is an honorable one. But electric vehicle (EV) technology can only go so far. Even EVs have their limits, so we need an alternative to electricity if we fully intend to do away with gasoline and diesel. Hydrogen and natural gas are viable choices.

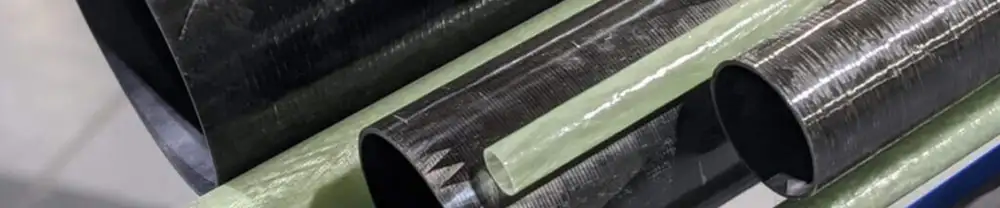

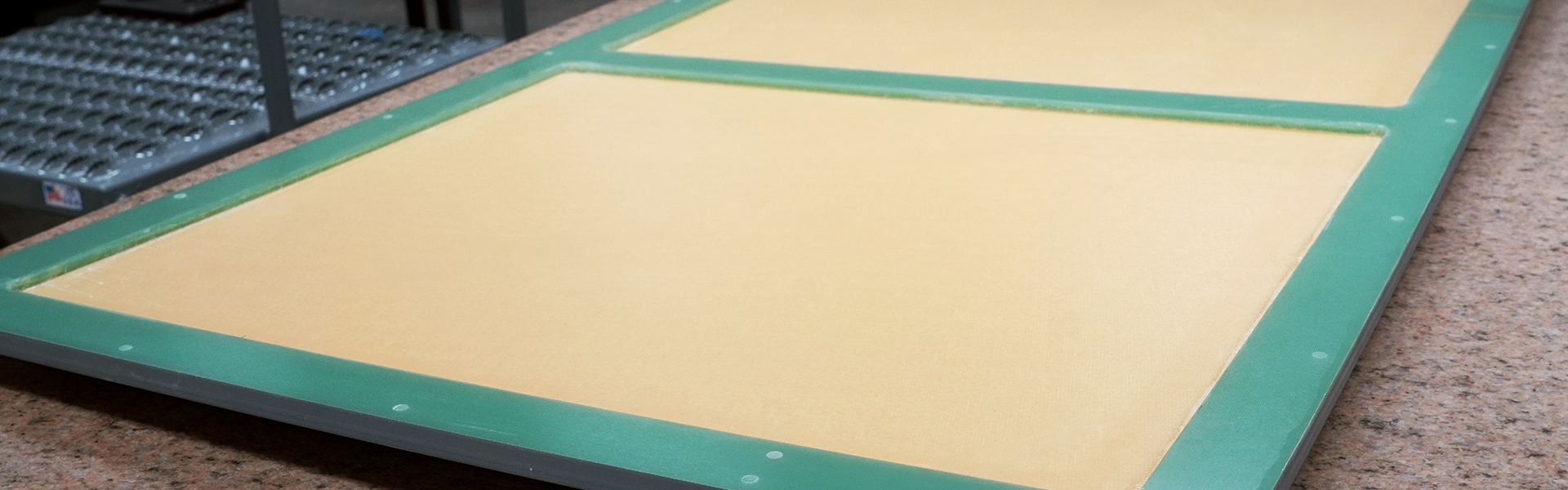

In order to make use of either gas as a daily transportation fuel, it has to be compressed. Furthermore, compressed gas must be contained in a high-strength tank not subject to deterioration and able to withstand significant crash impact. Carbon fiber is the perfect material. But it is also an expensive material.

The IACMI, which is essentially a consortium of universities, national laboratories, government agencies, and private sector companies, is tasked with finding a way to mass-produce carbon fiber fuel tanks at a more reasonable cost. Until the cost comes down, replacing gasoline and diesel with compressed hydrogen and natural gas is simply not doable.

Going Back to the Start

This particular project is somewhat unique in that it is not really focusing on the process of manufacturing the fuel tanks. There will be plenty of time for prototyping new tanks later on. Rather, the IACMI’s efforts are being squarely focused on manufacturing carbon fiber from the very beginning.

Producing the carbon fibers that eventually become tow and fabric is complicated and energy intense. You start with a precursor, generally PAN, and subject it to high heat and pressure in order to burn away unwanted material and force carbon atoms to align in long strands.

The higher the quality of the finished product, the more energy you need to produce it. The DOE is hoping to find a way to produce the same quality without expending as much energy. If they can do that, they can bring down the cost of carbon fiber manufacturing commensurate with their energy savings.

Encouraging Industry Collaboration

There is apparently a secondary goal for the DOE carbon fiber fuel tank project. That goal is to study how collaboration among the consortium’s partners leads to innovation. In other words, the DOE wants to know if large-scale collaborative projects yield more innovations than would otherwise be achieved through non-collaborative efforts.

It is an interesting question to look into. We just assume that multiple partners collaborating together naturally leads to more input, better ideas, and new innovations. Now the DOE wants to test those assumptions by way of one of the most critical projects it has embarked on in recent memory.

Here’s hoping the IACMI accomplishes the goals it has been tasked with. If it succeeds, fuel tanks will not be the only composite products that cost less. Cheaper virgin carbon fiber ultimately means cheaper composite parts for nearly every industry. That is why this project is so important.

copy.jpg)

copy.jpg)