Commercial Equipment Made Better with Composites

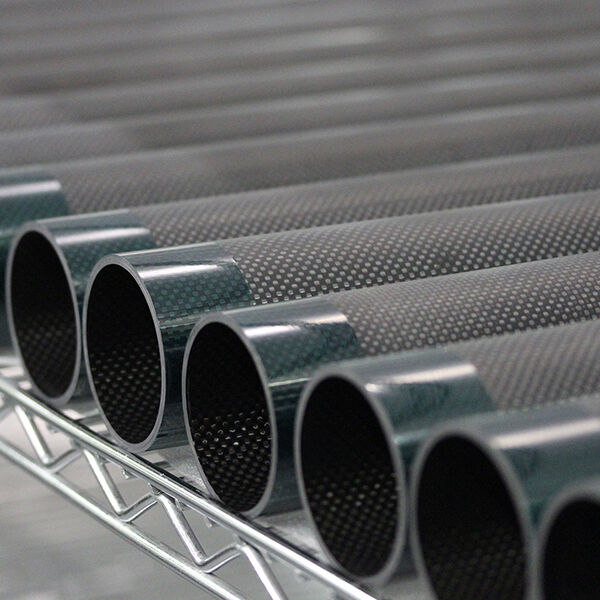

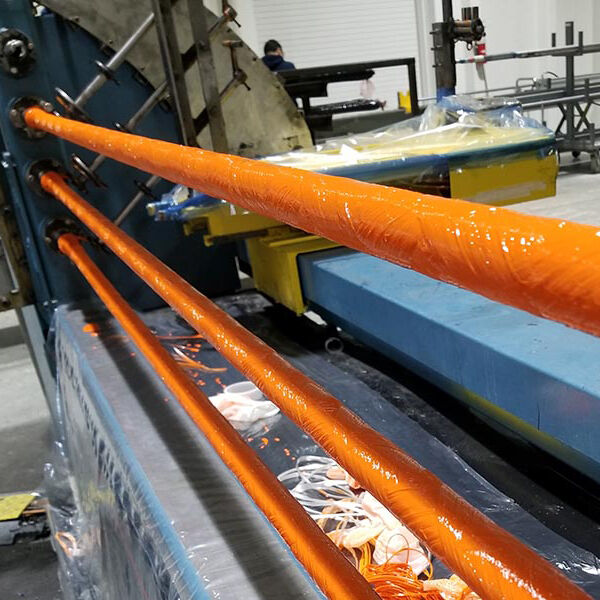

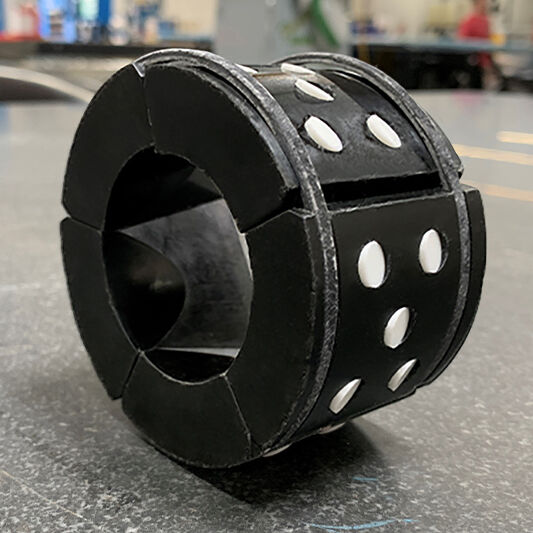

OUR SPECIALTY: Utilizing composite materials to engineer innovative components that maximize weight savings while maintaining structural integrity and cost efficiency

THE BENEFIT TO YOU: Our team translates years of heritage in aerospace into commercial markets, providing innovation and quality, while reducing risk and schedule.

OUR BUSINESS: Employee-owned, agile, responsive, QMS ISO 9001:2015 certified

THE TEAM: Experience in multiple verticals including industrial automation and robotics, energy, medical, metrology, converting, and other commercial industries.