Latest news from the Labs

FOR IMMEDIATE RELEASE

Rock West Composites’ Website Offers New Material Property Data and Calculators for Many of Its Ecommerce Products

This month Rock West Composites published theoretical material properties and launched several calculators for estimating the performance of rods and tubes offered on its website. Fulfilling a common need for engineers shopping for composite products, these reference calculators can help estimate deflection, failure mode, and failure loads in a variety of common load cases.

San Diego, CA (PRWEB) May 22, 2025 – Rock West Composites (RWC) announces the publishing of engineering properties for most products and the launch of several calculators on its website for tubes and rods. This information will help engineers estimate deflection, failure mode, and failure loads in a variety of common load cases for several product types offered. By publishing theoretical properties alongside a tool that can give a sense of behavior in a variety of load cases, RWC will enable the customer to find the best off-the-shelf solution for their needs.

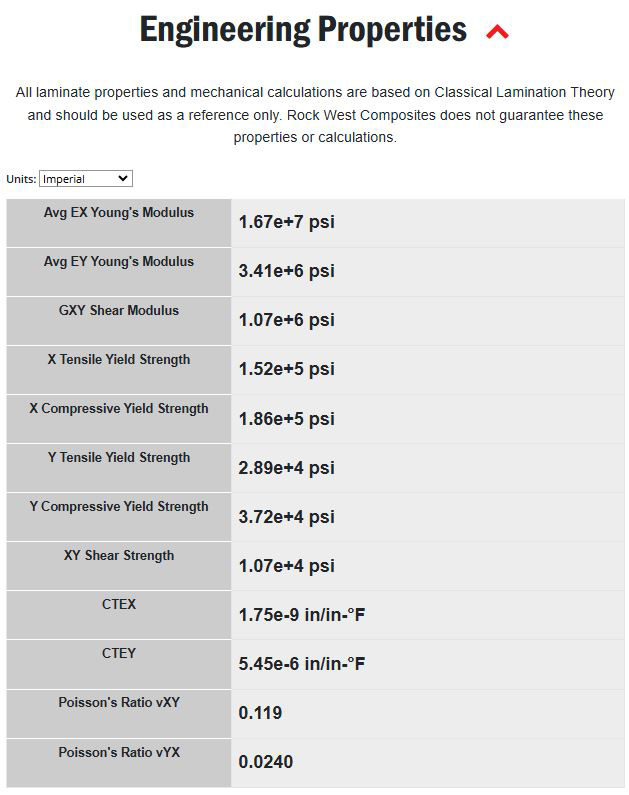

On individual product pages, customers will find a section called “Engineering Properties” that will include Young’s Modulus, Shear Modulus, Tensile Strength, Compressive Strength, Shear Strength, Coefficients of Thermal Expansion, Poisson’s Ratios, fiber layup, fiber type, resin type, and more. Laminate properties and mechanical calculations are based on Classical Lamination Theory and are provided for reference only.

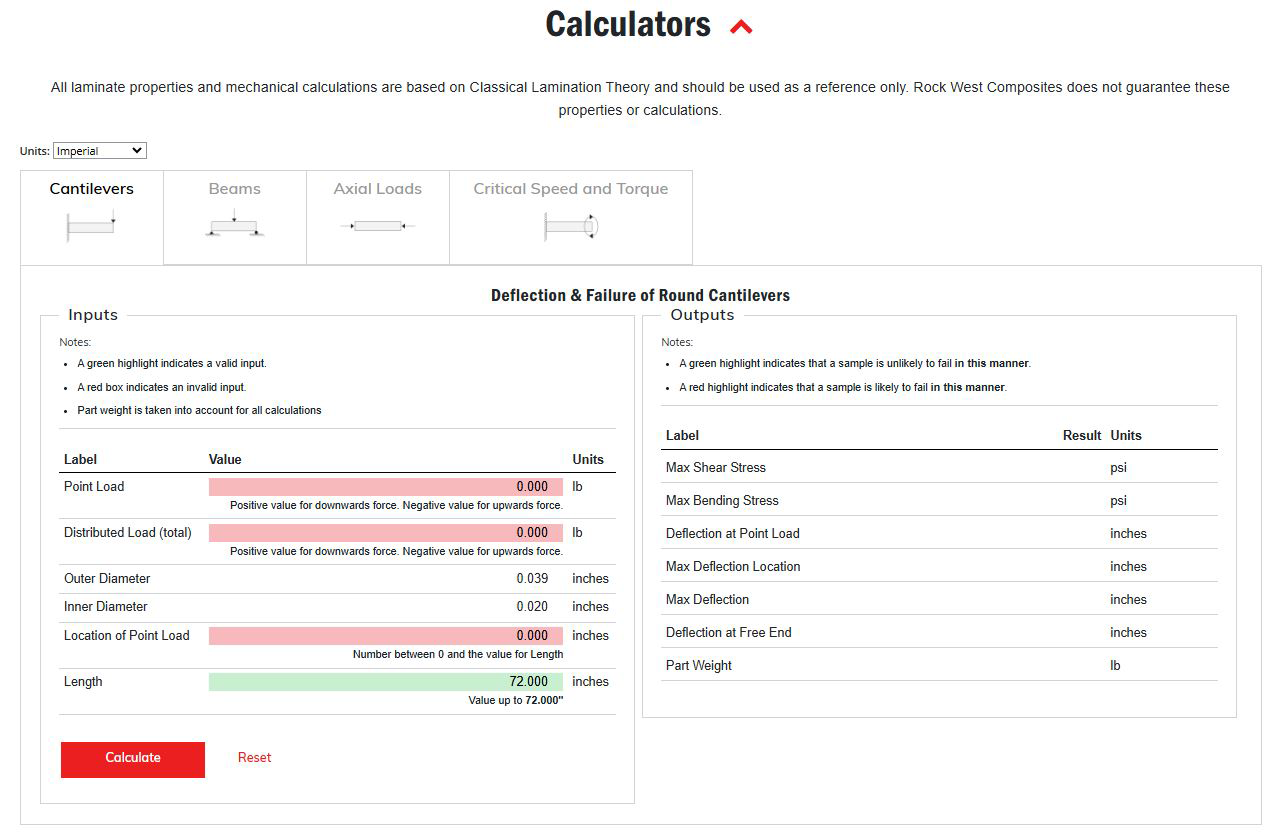

The calculators on pages for most tubes and rods will enable calculations for the estimated performance of cantilevers, beams, axial loads, and critical speed and torque. These tools allow for several fields of input and return theoretical results for properties such as maximum shear stress and bending stress, deflection at load point, maximum deflection and location, change in length, twist angle, and maximum allowable torque.

The properties and calculators will give engineers everything that they need to design with RWC’s off-the-shelf products. While the information provided is only theoretical, RWC does offer formal testing services if customers elect to advance to that level of support. Eventually, RWC plans to expand its calculators to plates, panels, shaped tubes, and other products.

“Customer often reach out to find out how much weight a tube can hold, what amount of deflection they can expect, or to find out what the material properties are for a specific part so that they can run their own simulations. We are excited to provide this information online on the product pages themselves, alongside tools that allow them to quickly run calculations for common use cases,” said Josh Lyon, eCommerce Product Technical Lead.

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Space (bus structures; solar array panels and wings; launch vehicle structures; optical, payload and deployable structures), Aerospace & Defense (radomes, munitions, unmanned systems, reflectors), Aircraft (new and replacement parts) and Commercial Equipment (automation, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s mission is to make customers more competitive with the magic of advanced composites by delivering highly differentiated products on time and on budget, all while making the buying process easy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

FOR IMMEDIATE RELEASE

Rock West Composites Delivers First Ultra-High-Performance Frac Plugs for New Contract

This month Rock West Composites begins the delivery of newly developed ultra-high-performance frac plug billets to an oilfield service company as part of a new contract. This product, developed and tested over the past year, can withstand cyclical testing at 12,000 psi and 250°F without failure.

San Diego, CA (PRWEB) April 28, 2025 – Rock West Composites (RWC) begins delivery this month of new ultra-high-performance frac plug billets to an oilfield service company that is a major supplier to the hydraulic fracturing market. RWC has developed a composite material for frac plugs that can withstand cyclical testing at 12,000 psi and 250°F without failure.

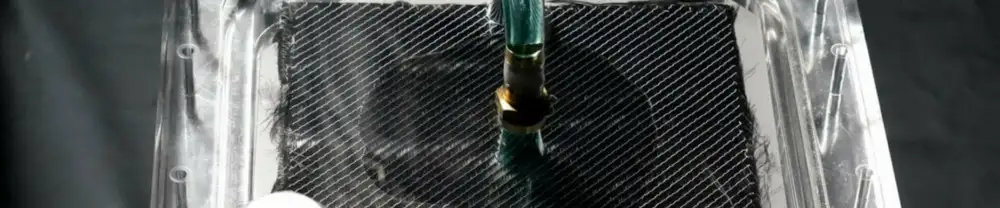

This new ultra-high-performance frac plug material has been in development for over a year. It is made of filament wound fiberglass composite with a custom epoxy resin. The plugs have passed rigorous testing in RWC’s laboratory and the customer’s in-situ downhole environments. Each lot is proof tested to guarantee performance for these extreme applications.

RWC manufactures and tests the plug billets at its facility in West Jordan, Utah, the location of its filament winding center of excellence. This facility has 27 spindles across multiple winders and the capacity to manufacture up to 6,000 billet tubes per month. RWC anticipates significant market demand for this product due to the increasing challenges oilfield service companies face with downhole operations.

“We brought our filament winding expertise to the table. Our engineering team works on highly demanding applications, including space and aerospace, so we took that knowledge of material performance downhole,” said Adam Creer, Commercial Segment Director. “We are glad to have partnered with our customer to meet their very demanding requirements and develop our own technology that solves an industry-wide challenge.”

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Commercial Equipment (industrial, medical, energy, and sporting), Space (bus structures; solar array panels and wings; launch vehicle structures; optical, payload and deployable structures), Aerospace & Defense (radomes, munitions, unmanned systems, reflectors), and Aircraft (new and replacement parts). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s mission is to make customers more competitive with the magic of advanced composites by delivering highly differentiated products on time and on budget, all while making the buying process easy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico.

www.rockwestcomposites.com

#######

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

FOR IMMEDIATE RELEASE

Rock West Composites Delivers Panels for 500-Watt Arrays to Astro Digital for their Higher-Power Buses This month Rock West Composites delivered panels for Astro Digital’s new 500-Watt arrays to support higher power versions of Astro Digital’s Corvus buses. RWC built the sandwich panels from trace/lead integrated skins that allowed for direct integration with solar cells, saving weight and integration time for the customer.

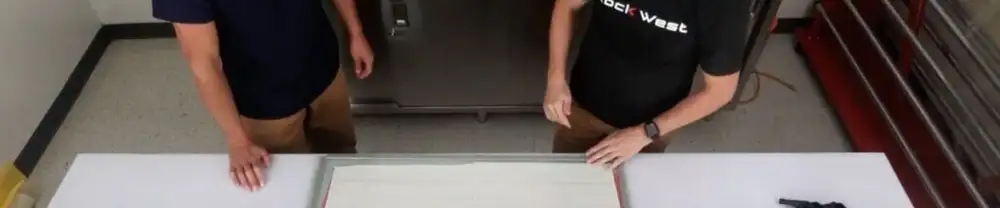

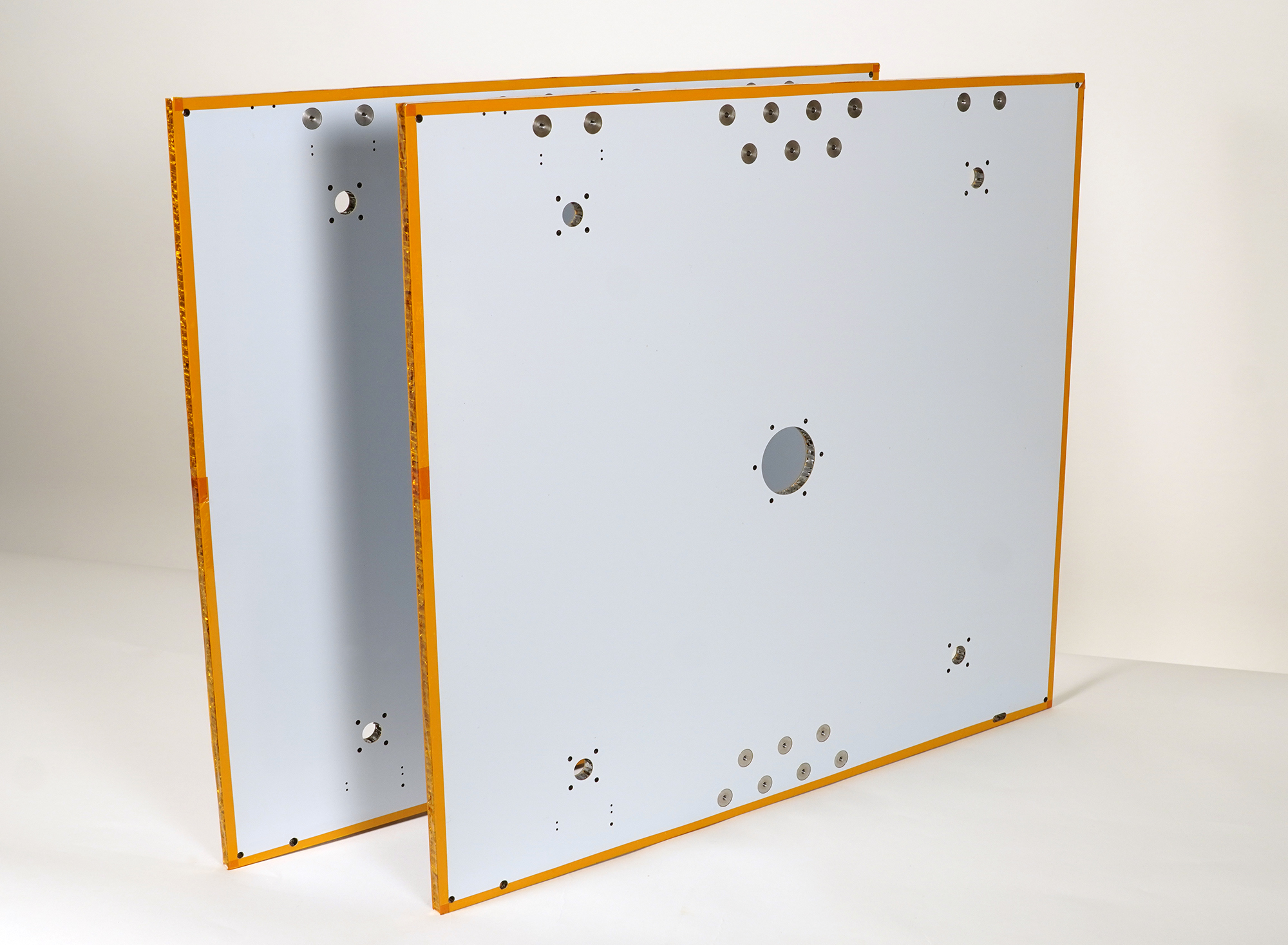

San Diego, CA (PRWEB) June 27, 2024 – Rock West Composites (RWC) announces the delivery this month of panels for Astro Digital’s new 500-Watt arrays to support higher power versions of their Corvus buses. RWC teamed with Astro Digital to fabricate solar array substrate (SAS) panels with a unique integrated design to save volume and weight. These panels are being integrated into space vehicles, the first of which is scheduled to launch in October.

These SAS panels are unique in that RWC built the sandwich panels from trace/lead integrated skins that allowed for direct integration with solar cells. This reduced total weight and shortened the integration time. The customer furnished the G10 (fiberglass) skins that already had the integrated copper traces. RWC used specialized tooling to align the face skins on the aluminum honeycomb core to keep the traces in the right location during fabrication of the approximately 2’ x 2’ structures.

Jeremy Senne, Space Segment Director, said, “This is a great example of how we can help our customers solve their problems in innovative ways. It was a tooling and machining challenge to work with their pre-integrated skins, but our experience on other precision programs enabled successful fabrication.”

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Space (bus structures; solar array panels and wings; launch vehicle structures; optical, payload and deployable structures), Aerospace & Defense (radomes, munitions, unmanned systems, reflectors), Aircraft (new and replacement parts) and Commercial Equipment (automation, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s mission is to make customers more competitive with the magic of advanced composites by delivering highly differentiated products on time and on budget, all while making the buying process easy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Marketing Director

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

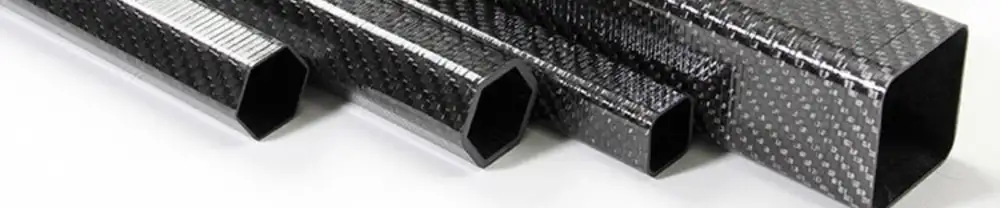

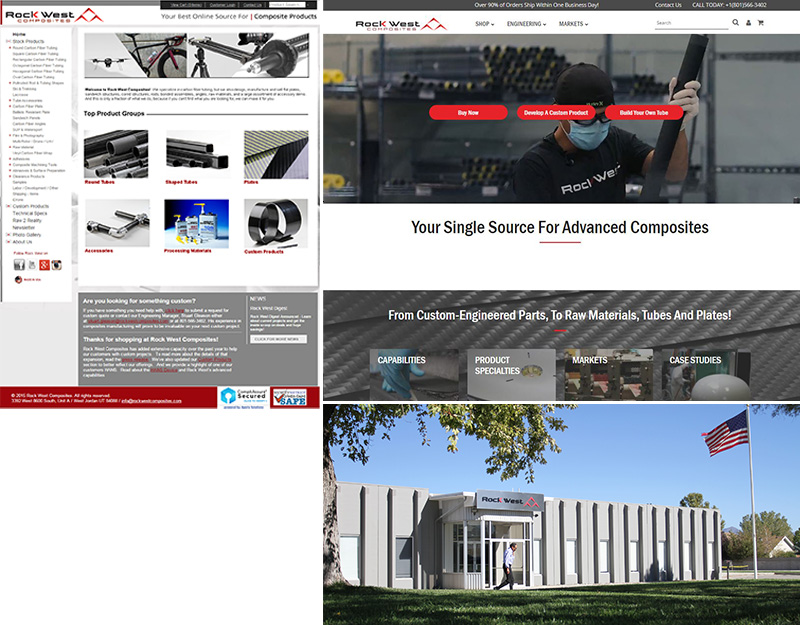

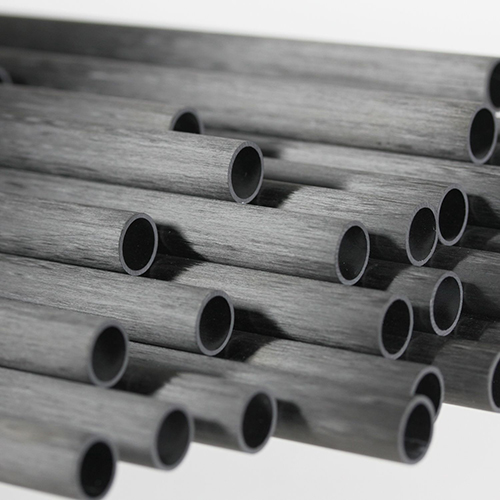

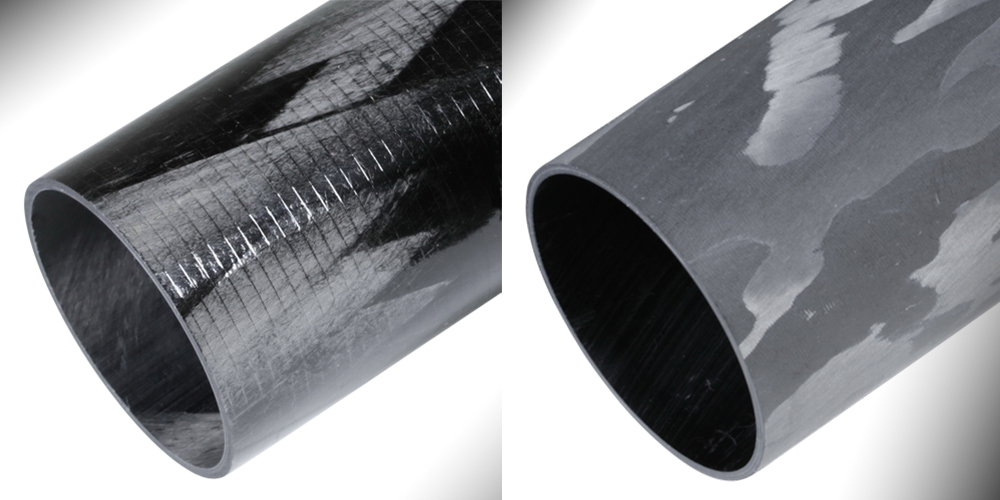

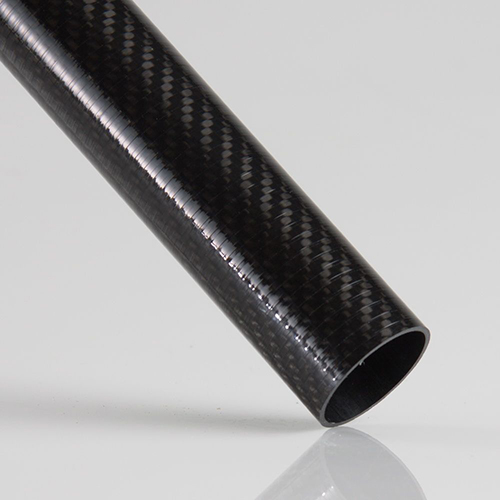

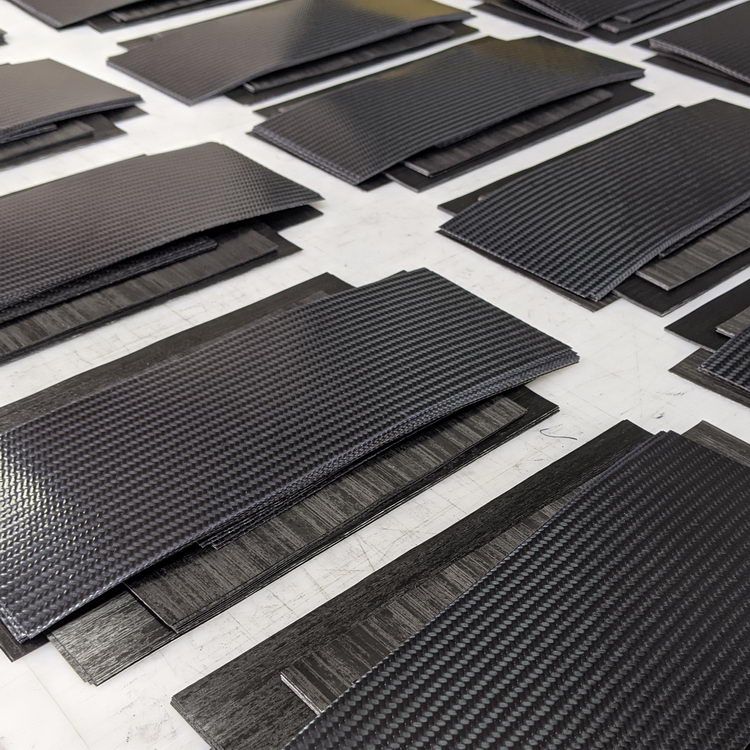

Our Ecommerce Origins Story

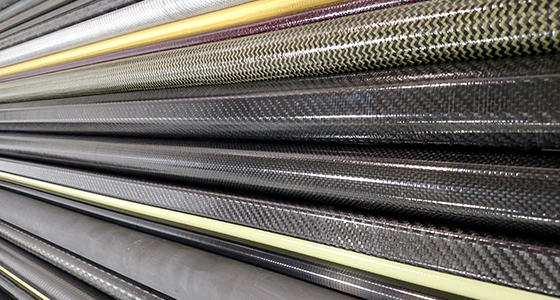

In 2009, rockwestcomposites.com became one of the first online merchants for carbon fiber tubes, plates, panels, connectors, and materials. Over the past 15 years, our value proposition has always been that more than 94% of the items we stock ship within 24 hours. While this quick ship promise is great for last-minute needs, the fluctuation of demand forced us to continually scale back the number of items we listed for sale. While Rock West Composites owns over 3,000 mandrels, we were listing under 1,600 tubes for sale.

New Product Success

In 2023, we tried something different. We the first-of-offered-its-kind selection of off-the-shelf, space-ready items called STRATO™. Our value proposition was no longer centered around 24-hour shipment. It stated that we had the materials, tools, certifications, and people power to produce these standard items in 4-6 weeks, far faster than a custom solution. This approach allowed us to offer a far larger selection of tubes, plates, panels, and materials to our customers than if we tried to make them and keep them in stock. The product has been very successful. We've helped numerous customers shave weeks off their schedules while enjoying the cost benefits of using a stock item versus a custom solution.

Sitewide Product Expansion with Rapid Production

Building upon the success of the STRATO™ program, we are expanding this concept into everything we do. While we will continue to stock fast moving items, we will also list many items that we have the materials, tools, and peoplepower to produce quickly upon your order. Almost all items will be available within 4 weeks of order placement. We are also expanding the number of raw components we sell and are actively engaging with other manufacturers to sell their products on our site. We want rockwestcomposites.com to be your one-stop for everything you need to complete your advanced composites project.

Plan on Success!

We are excited about these changes as we believe they will provide you, our customers, access to significantly more off-the-shelf solutions for your projects. And while you will have to plan and order a little further in advance, you will have many more items to choose from. As always, if you do run into a time crunch, let us know. We may have alternative solutions or expedited services that can meet your deadline.

New Website in May

We are targeting May for our website launch. Please check out the new site, and if you don't see a product that you think we should be carrying, drop us an email at marketing@rockwestcomposites.com, and we'll do everything we can to add it.

FOR IMMEDIATE RELEASE

Rock West Composites Delivers to Purdue University

the Barrel Timing Layer Tracker Support Tube for CERN’s Large Hadron Collider

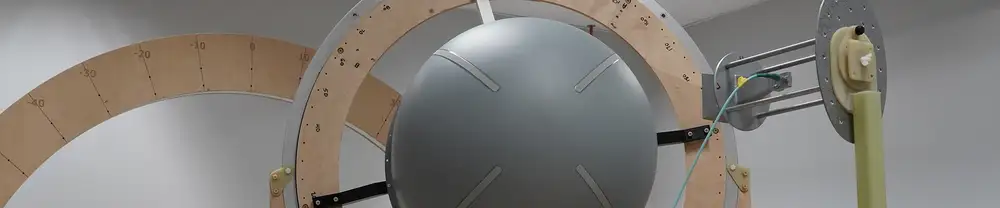

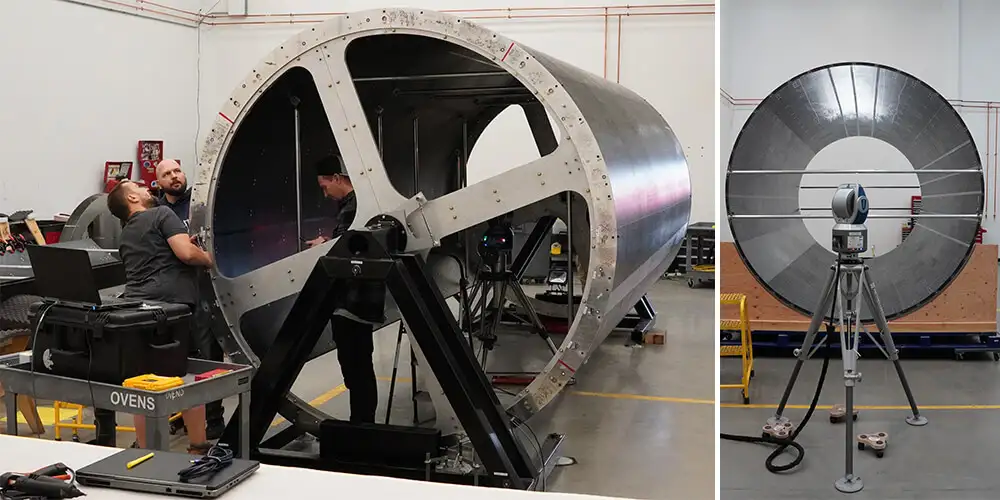

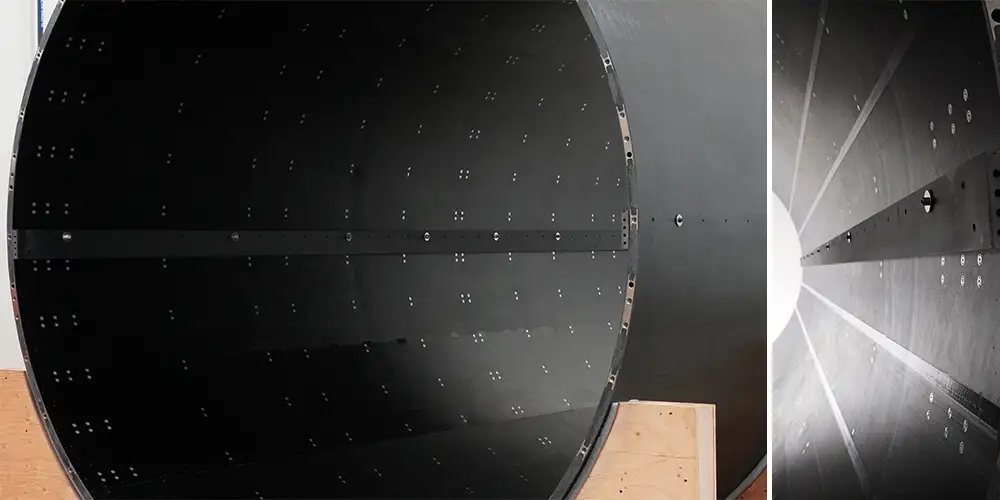

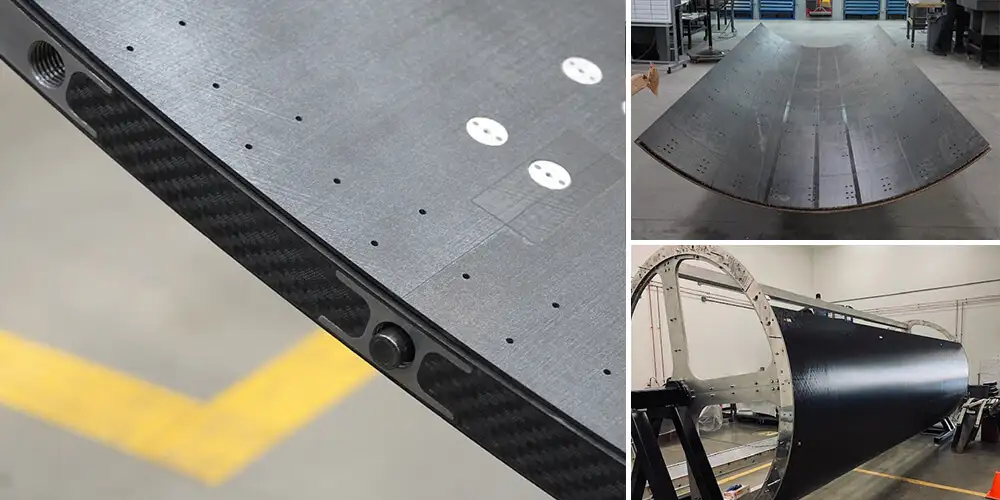

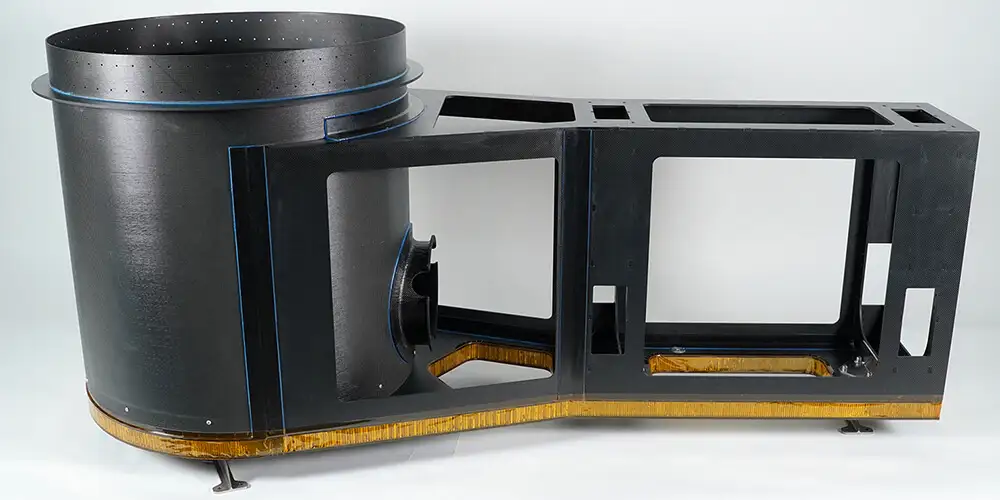

This month Rock West Composites delivered a large, high-precision, carbon fiber and honeycomb core tube to Purdue University. The structure is the Barrel Timing Layer Tracker Support Tube that is part of an upgrade to CERN’s Compact Muon Solenoid (CMS), which is a general-purpose detector at the Large Hadron Collider.

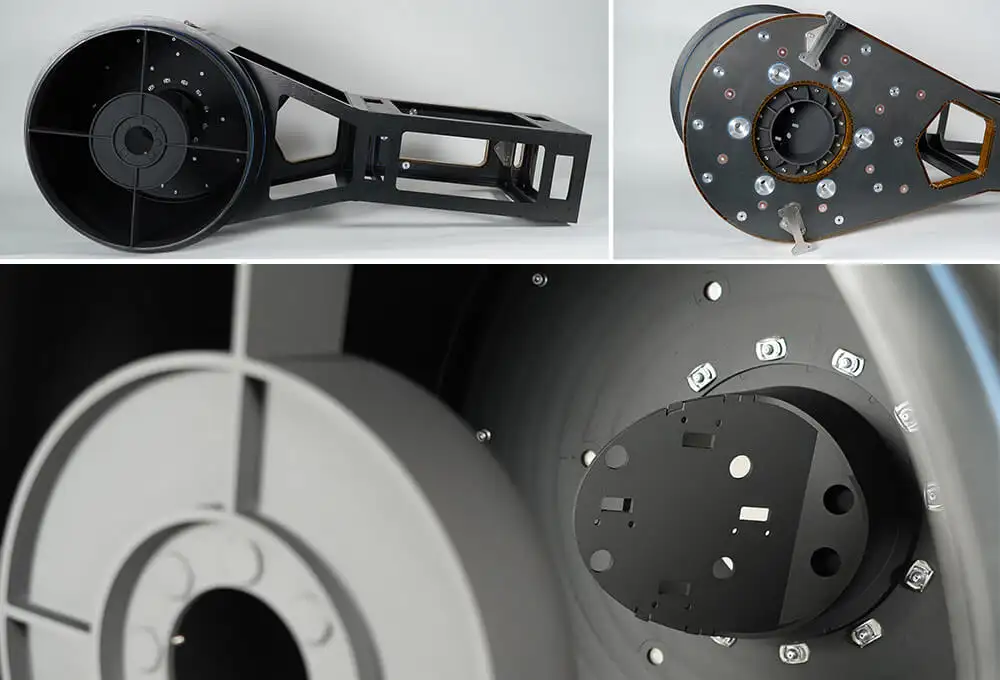

San Diego, CA (PRWEB) March 9, 2024 – Rock West Composites (RWC) announces the delivery of the Barrel Timing Layer (BTL) Tracker Support Tube to Purdue University this month. This large carbon fiber sandwich structure destined for CERN was designed by a joint team from Purdue University, led by Dr. Andy Jung and Dr. Ben Denos, and RWC, led by John Marks. The collaborative effort met key performance parameters using the most cost-effective design. The hardware RWC delivered will be integrated with instrumentation from Purdue prior to delivery to CERN.

CERN is the world’s leading laboratory for particle physics located near Geneva, Switzerland. The carbon fiber tube supports the heart of the upgraded CMS detector, a “camera” with more than a billion pixels to record proton-proton collisions at the highest ever-made energies and unprecedented resolution. In a few years, once fully commissioned, the upgraded CMS detector is expected to collect 10 times the data recorded so far in the hunt for new particles and aims to understand the origins of the Universe.

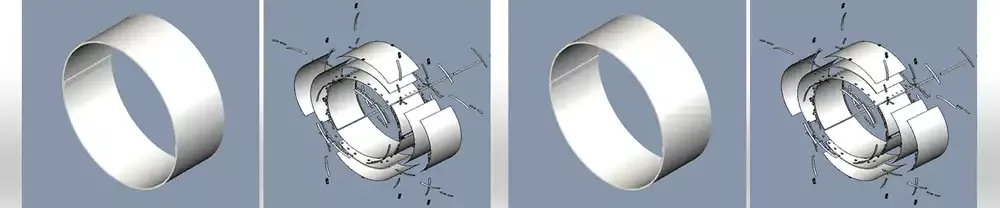

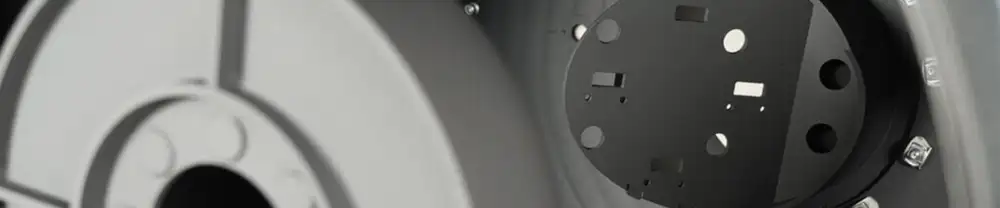

Tube under manufacture and inspection

The BTL Tracker Support Tube had to be manufactured from materials with extremely low radiation resistance, have a precise circular cylinder structure, be very strong and stiff, and meet an accelerated delivery schedule. Because the final tube had such challenging requirements, traditional tooling or manufacturing approaches would have been unaffordable. Innovative techniques were used, starting with the manufacture of curved, solid laminate arc segments rather than a full cylinder. Precision machined arc segment stiffeners help hold the arcs to strict dimensions once assembled. Low coefficients of thermal expansion are maintained in all 3 directions: radially, circumferentially, and along the length of the tube.

Completed hardware with the tooling used for manufacture

Prior to making the full-scale tube, RWC built a full diameter but much shorter version of the part as a technology demonstrator. RWC was presented with an Industry Gold Award from CERN in 2022 for this effort, and ultimately won the program from Purdue for the full-size hardware due to the success of the demonstration model and its affordability.

The delivered hardware is 5.3-meters long by 2.4-meters in diameter. It is constructed of ultra-high-modulus prepreg and Nomex honeycomb core made with PMT-F6 cyanate ester resin. There are 1680 metallic inserts made of solid carbon epoxy, titanium and stainless steel; and it includes two 110 MSI carbon fiber (K13916/ F6) rails to support scientific instruments. Surface accuracy requirements were tested to 2.4mm cylindricity inhouse before shipment.

Images show details of the interior of the tube with hundreds of inserts and railing system

John Marks, VP of Product Development, said, “We were excited to take on this challenging program and to know that we will be contributing to the advancement of humanity’s understanding the fundamental construct of matter. Our work on the demonstration model and final hardware pushed our team’s technical skills to the limit, and we couldn’t be prouder of their performance on this program.”

The Rock West team posing in front of the completed hardware the day before it was shipped

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Aerospace & Defense (radomes, aircraft, and weapon components), Space (bus structures, solar array panels and wings, strut assemblies, launch vehicle structures), and Commercial Equipment (industrial, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s vision is to “make the magic of composite technologies accessible to the world” by executing flawlessly and providing customers a competitive advantage, all while making it easy to buy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico.

www.rockwestcomposites.com

#######

For more information:

Julia Willis, Marketing Director

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

FOR IMMEDIATE RELEASE

Rock West Composites’ Components Are on Intuitive Machines’ IM-1 Mission to the Moon

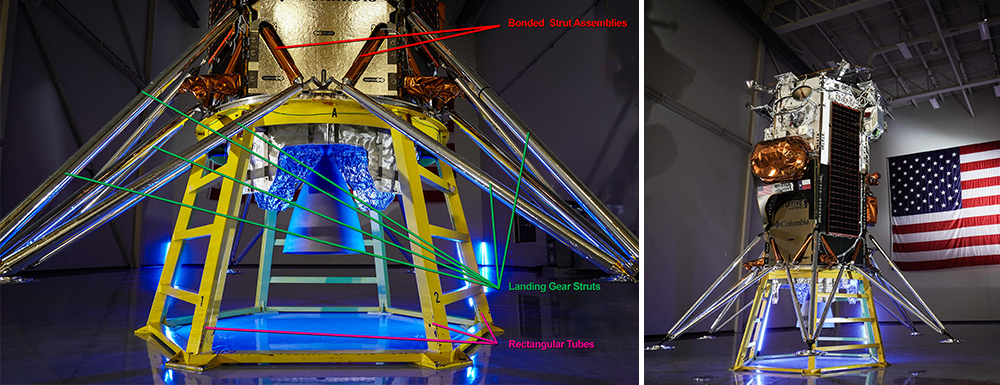

Supporting the commercial space race to the Moon, Rock West Composites is proud to have provided multiple configurations of struts to Intuitive Machines for incorporation into its Nova-C lunar lander named Odysseus, which launched last week. The struts met challenging surface profile and straightness requirements for both interior and exterior dimensions, were integrated with bonded fittings, and were pull-tested in-house before delivery.

San Diego, CA (PRWEB) February 21, 2023 – Rock West Composites (RWC) provided hardware to Intuitive Machines for incorporation into its recently launched Nova-C lunar lander, Odysseus. Intuitive Machines’ IM-1 Mission is sending its lander to the Moon as part of NASA’s Commercial Lunar Payload Services (CLPS) initiative and Artemis campaign. RWC delivered multiple configurations of machined and tested struts with bonded fittings. The struts included both circular cross-section tubes with and without bonded titanium fittings, and rectangular tubes with a tooled surface on both the inside and outside face.

IM-1 Lunar Lander Odysseus with RWC Struts and Assemblies (Odysseus images courtesy Intuitive Machines – Nick Rios)

The RWC-provided struts were primarily constructed of HM63/PMT-F6 unidirectional prepreg with 0.010” and tighter surface profile and straightness requirements. The rectangular tubes were especially challenging due to the tooled surface requirement on both the interior and exterior with a tight surface profile requirement on both sides to allow for next-level assembly tolerances. The hardware was build-to-print, but RWC provided input on the final design for manufacturability and requirements compliance. The struts with bonded fittings were pull-tested in-house at RWC prior to final integration at Intuitive Machines.

RWC Strut Assemblies

“We are honored to support our commercial customers in this race to the Moon and ultimately a sustained human presence there,” said Jeremy Senne, RWC’s Space Segment Director. “Our precision composite components can give our customers the performance they need to succeed in this high-risk and clearly challenging business.”

For more information on this mission: https://www.intuitivemachines.com/im-1

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Space (bus structures, solar array panels and wings, strut assemblies, launch vehicle structures), Aerospace & Defense (radomes, aircraft, and weapon components) and Commercial Equipment (industrial, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s vision is to “make the magic of composite technologies accessible to the world” by executing flawlessly and providing customers a competitive advantage, all while making it easy to buy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico.

www.rockwestcomposites.com

About Intuitive Machines

Intuitive Machines is a diversified space company focused on space exploration. Intuitive Machines supplies space products and services to support sustained robotic and human exploration to the Moon, Mars, and beyond. Intuitive Machines’ products and services are offered through its four business units: Lunar Access Services, Orbital Services, Lunar Data Services, and Space Products and Infrastructure. For more information, please visit intuitivemachines.com.

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

FOR IMMEDIATE RELEASE

Rock West Composites Ships First Set of

Solar Array Substrate/Back-Up Structure Assemblies for the DiskSat Program

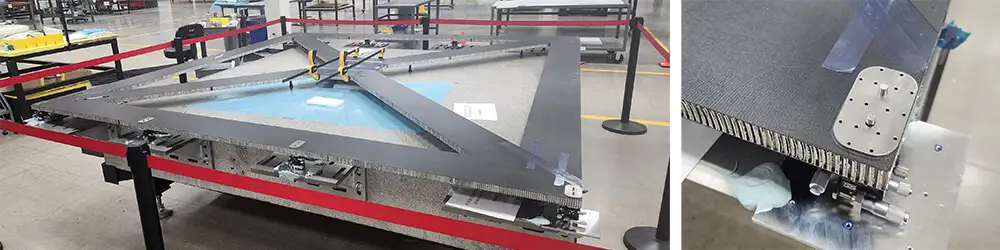

Rock West Composites announces that this month it shipped the first four solar array substrate/back-up structure assemblies to The Aerospace Corporation in support of the DiskSat Program. The company, whose engineering team consulted on the substrate and assembly design, used their space-grade, off-the-shelf STRATO™ panels to reduce cost and lead times, plus met positional tolerances of 0.010”-0.020” without costly assembly fixtures.

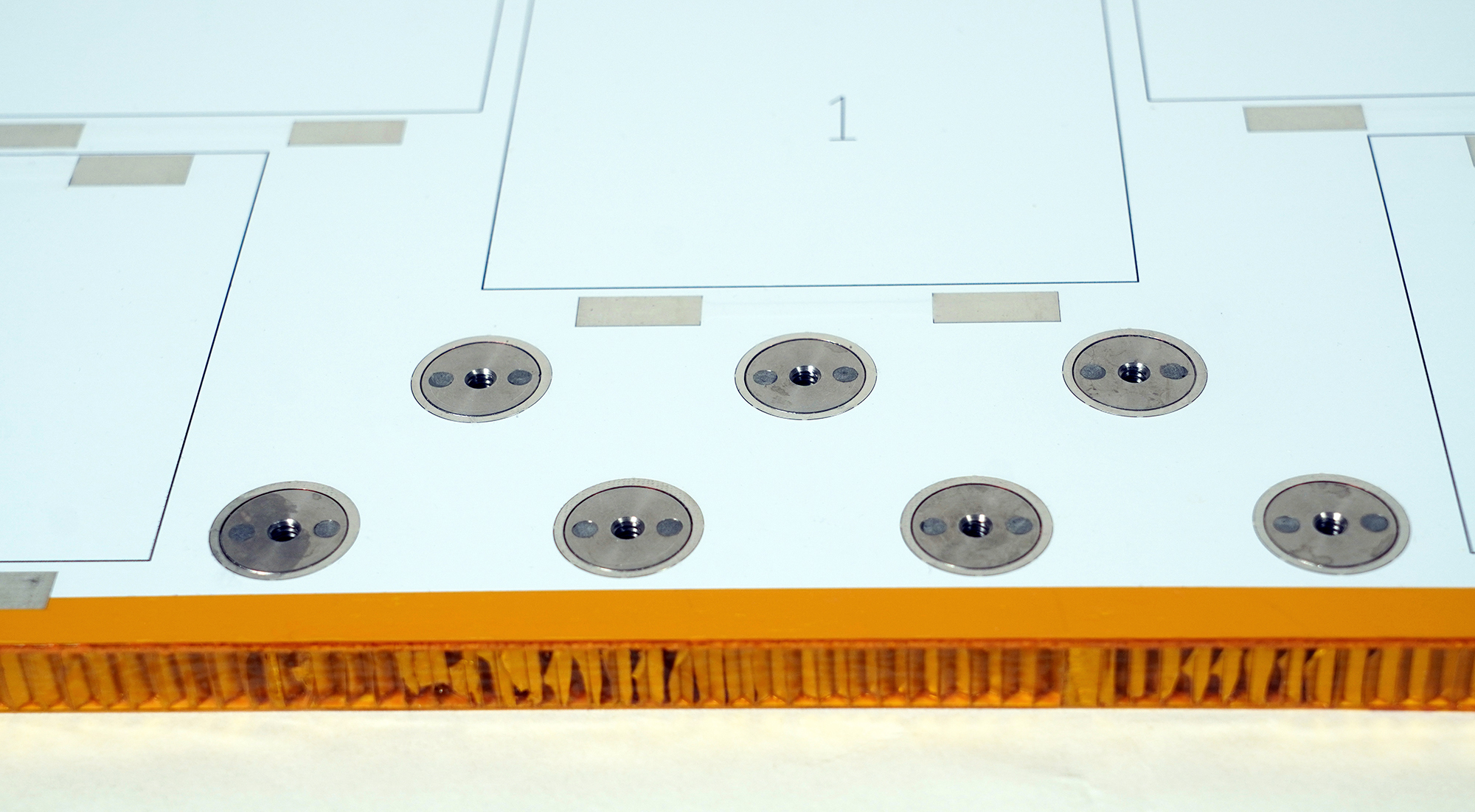

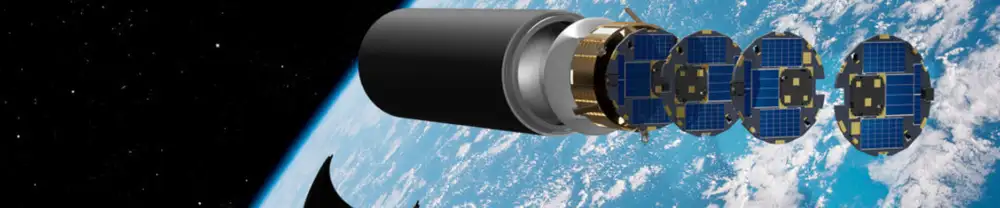

San Diego, CA (PRWEB) January 31, 2023 – Rock West Composites (RWC) delivered four combination solar array substrate/back-up structure assemblies to The Aerospace Corporation in support of the DiskSat Program this month. DiskSat is a NASA-funded technology demonstration program that seeks to verify the performance and deployment method of this new small-spacecraft platform. The disk-shaped satellite design has the potential to revolutionize smaller space missions through its high power, large aperture form factor that fits in the circular cross-section of a rocket fairing. By using its own off-the-shelf, space-grade STRATO products, RWC was able to significantly reduce lead time and cost, while helping define structural properties to support the mission’s innovations. If successful, follow-on missions are possible, and other prime contractors may look to use a similar form factor for volumetric and weight efficiencies.

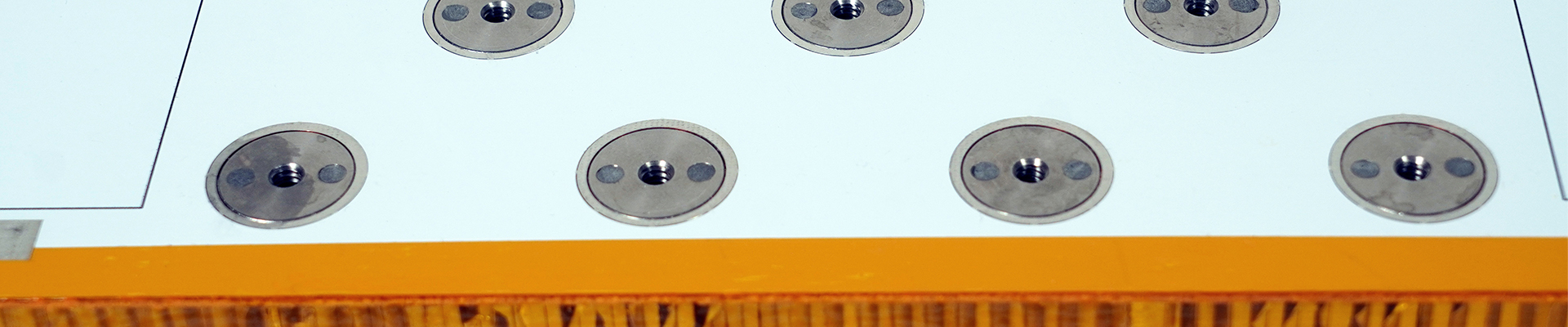

Set of four DiskSat Assemblies

Providing additional services for this build-to-print program, the RWC engineering team consulted on the design including layup, material selection, insert design, bonding methods, and manufacturing strategy. RWC used its own product, the STRATOSubstrate™ LEO class, to ensure a cost-effective solar array substrate. The team used an insert design that allowed for self-fixturing to a tight tolerance, avoiding a costly assembly fixture. The tolerances on the in-plane and out-of-plane inserts match to a global datum scheme, and tolerances were on the order of 0.010-0.020” positional.

The use of STRATOSubstrate LEO panel blanks significantly reduced raw material and blank lead time. STRATOSubstrate LEO class panels use HR40/NB321 unidirectional prepreg, NB301 film adhesive, perforated aluminum honeycomb core, and 0.002” HN Kapton. The inserts for the deliverable were BR-127 primed aluminum bonded with EA9394. The final assembly measures approximately one meter in diameter and 25 centimeters in thickness.

Close-up of the DiskSat assemblies

Detail of DiskSat assemblies’ inserts

“Saving our customer cost and lead time for this innovative and game-changing program by using our STRATOSubstrate LEO class of panels is exactly why we developed the STRATO product line,” said Jeremy Senne, RWC’s Space Segment Director. “We are excited about the potential for this new form factor in the exploration of space.”

About Rock West Composites

Rock West Composites is an employee-owned, advanced composites company. RWC develops, engineers, manufactures, and tests composite products for multiple industries including Space (bus structures, solar array panels and wings, strut assemblies, launch vehicle structures), Aerospace & Defense (radomes, aircraft, and weapon components) and Commercial Equipment (industrial, medical, energy, and sporting). The company is also one of the largest ecommerce suppliers of off-the-shelf carbon fiber tubes, plates, materials, and accessories.

The company’s vision is to “make the magic of composite technologies accessible to the world” by executing flawlessly and providing customers a competitive advantage, all while making it easy to buy. Rock West Composites has locations in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico.

www.rockwestcomposites.com

About The Aerospace Corporation

The Aerospace Corporation is a nonprofit corporation that operates a federally funded research and

development center, providing technical expertise and objective analysis for our nation’s space programs. aerospace.org

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

We often have customers who need a custom product fast, and at high volume. Here is one of those products. This week we delivered a series of about a 150 radome covers that were custom designed, manufactured, machined, painted and finished within a short turnaround window. While we can do large, complex structures with all the rigid requirements needed for space applications, we can also handle a fast turnaround, simple programs that can meet baseline technical requirements affordably.

Rock West worked in close collaboration with this customer, from the initial concept to full production run. We went through multiple design iterations to achieve RF performance and manufacturability. Several prototypes were created and performance tested before the design was finalized. Using in-house machining and painting capability helped to keep schedule short and low risk.

Radomes are an area of specialization for Rock West. You can read more on our Radomes page.

Radome covers, corner view

Subset of the radome covers delivered to our customer

Generally speaking we love the composites business, but we really get excited about programs that test the limits of carbon fiber technology and contribute to scientific discovery.

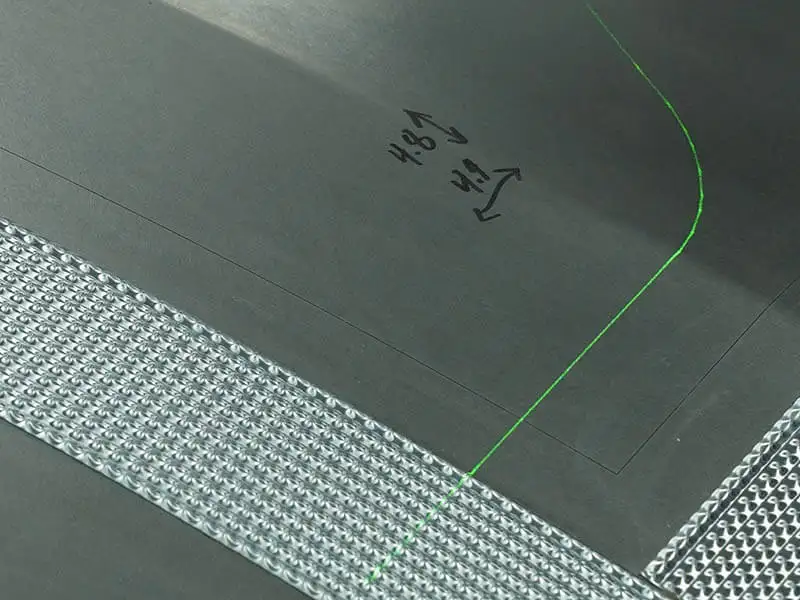

Last year we told you about this amazing prototype project we were working on with Purdue University for CERN. The prototype was designed and built for the CMS (Compact Muon Solenoid) detector. We are now hard a work on the final hardware and it’s looking great! Here are some in process pictures. We look forward to sharing more once it’s finished!

Layup of large, curved, carbon fiber panel with honeycomb core

Large panel with inserts, large tool for assembly, and edge detail

Telescoping tubing has so many practical uses and can be used in everything from window washers to selfie sticks. But sometimes you can't find the right length you need for your purposes. While building your own set can get you exactly what you want (and we are happy to provide all the supplies you need to do it), the process can be time consuming to design and assemble the structure. We have a great solution for you! We now offer fully assembled telescoping tubing from two of our lines: INFINITubeV and INFINITubeUL .

Our INFINITubeV Telescoping Tubes provide the perfect balance of strength and lightweight design. This product utilizes our standard modulus tubes, with a classic carbon fiber twill weave strength and esthetic. Engineered for seamless extension and retraction, these tubes offer unmatched versatility for a range of applications, providing exceptional strength without the added weight of heaviest material. For this line, you can choose between our compression ring twist clamps or our new proprietary Flip and Twist locking clamps (more details below!).

Our Ultralight Telescoping Tubes utilize standard modulus unidirectional tubes and provide the strongest strength to weight ratio of our telescoping tube options. This set provides the same seamless extension and retraction, versatility and strength. This is just much lighter. This model utilizes compression ring twist clamps.

Both of these lines have medium, long, and extra-long options with 3, 4 or 5 segments respectively. The collapsed and extended length depends on the line since each line has different tube lengths. For details, review the specifications on the individual product pages.

Compression ring twist clamps (left) and our flip and twist locking clamps (right)

NEW Flip and Twist Locking Clamps

These flip and twist locking clamps are made specifically to work with our INFINITubeV Telescoping Tubes , and they are faster to lock and release than our compression ring twist clamps. They are manufactured with PA12GB 40% glass filled & blacked nylon, meaning it has high stiffness and temperature resistance. If you are building your own telescoping tube set, these clamps can be secured to the base (larger) tube in the assembly with a cyanoacrylate adhesive or the supplied screw (for dis-assembly). But why build your own when you can buy it assembled already ?

FOR IMMEDIATE RELEASE

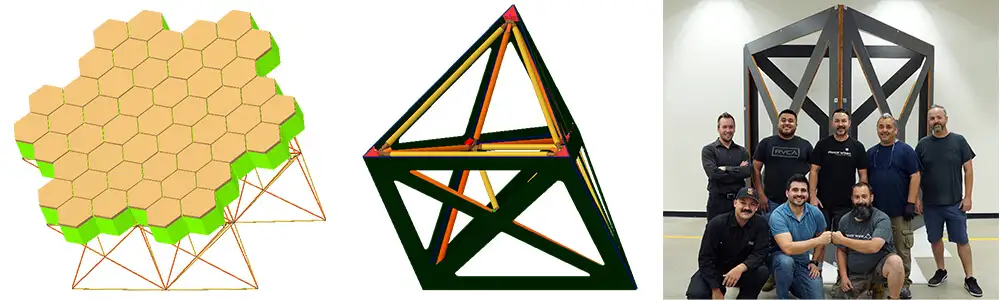

Rock West Composites Delivers Completed Assembly Fixtures for the NASA PASS Program

Rock West Composites announces that this month it has delivered three 9 ft. by 9 ft. assembly fixtures that are part of the Precision Assembly Space Structure (PASS) program supporting NASA’s On-orbit Servicing Assembly and Manufacturing (OSAM). Designed with tight tolerances for thermal and moisture stability, the fixtures also required 0.002 in. flatness across 9 fittings and 0.002 in. positional tolerance across the holes and slots for those fittings encompassing the full 9 ft. by 9 ft. panel.

San Diego, CA (PRWEB) August 18, 2023 – This month Rock West Composites (RWC) delivered three assembly fixtures for NASA’s Precision Assembly Space Structure (PASS) program supporting the On-orbit Servicing Assembly and Manufacturing (OSAM) efforts. These fixtures are part of NASA’s push for next generation manufacturing technology that will enable in-orbit construction of high-precision hardware, such as reflectors and antennas, for programs such as Artemis.

Left: CAD image of NASA PASS Reflector assembled (Credit: NASA Langley) Center: CAD image of segment of structural supports with assembly fixture (Credit: NASA Langley) Right: RWC Program Team with completed assembly fixtures

Left: CAD image of NASA PASS Reflector assembled (Credit: NASA Langley) Center: CAD image of segment of structural supports with assembly fixture (Credit: NASA Langley) Right: RWC Program Team with completed assembly fixtures

RWC helped define the requirements and designed the hardware to meet the challenging operational parameters for these fixtures. There are 9 holes and 9 slots on 9 fittings which required a positional tolerance of 0.002 in. The 9 fittings also required a flatness across the fixture of 0.002 in. The panel has to interface with a strut assembly and have very low coefficients of thermal and moisture expansion to ensure high precision and repeatability.

Laser tracker inspection results of panel tolerances

RWC used a spliced panel design to meet the 9 ft. by 9 ft. sizing. Innovative soft fixturing with fine tuning adjustment capability was used to meet tight tolerances in a cost-effective manner. A laser tracker was used to verify tolerances during manufacture.

Left: Panel in manufacturing on adjustable fixtures for precision tuning Right: Detail of single insert adjustable fixture

“We are proud to be part of this program supporting NASA’s mission infrastructure and pushing forward space technology,” said Jeremy Senne, the head of RWC’s Space market segment. “When we can find ways to innovate our manufacturing process that ultimately save our customer time and money, it’s a win-win. We hope to recycle this process for similar large and tight tolerance structures to continue to push the envelope of what’s possible.”

For more information on Rock West Composites’ capabilities, visit www.rockwestcomposites.com.

About Rock West Composites

Rock West Composites is an employee-owned enterprise that develops and manufactures composite products for multiple industries including aerospace, defense, space, radomes, commercial, industrial, medical, energy, and sporting goods. The company is also one of the largest Ecommerce suppliers off-the-shelf carbon fiber tubes, plates, materials, and accessories. Specializing in carbon fiber and RF-transparent composite materials, RWC offers custom products and off-the-shelf solutions that enable customer success by finding innovative solutions to complex problems across the product lifecycle, from concept to design, and prototype to final hardware production. Rock West Composites has facilities in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico.

Originally developed in the 1980’s, the HANS device has been one of the most innovative components in racing safety, as it greatly limits the forward head and neck movement of the driver upon impact. HANS devices have been mandated in NASCAR’s top 3 series since 2001 and by Formula 1 since 2003. Many other major auto racing series followed suit and mandated the HANS device in their races after seeing the impressive life-saving results of this safety equipment.

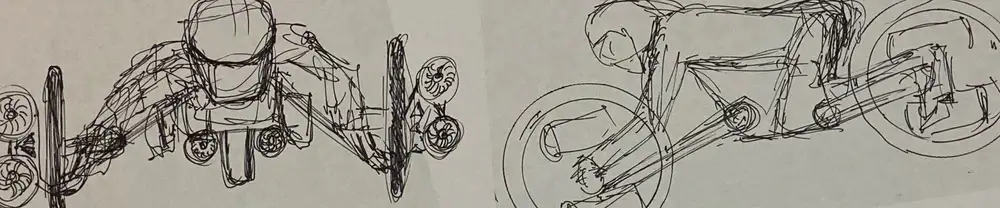

For over 10 years, Rock West Composites has proudly manufactured carbon fiber HANS devices for Simpson Race Products. Rock West began manufacturing the HANS Pro Ultra device in our Salt Lake City facility. The product design required stringent specifications, including the ability to withstand 10G front impact without failure. The retail-quality gloss finish had to withstand a corrosive environment. As the demand for a lighter weight product materialized, we added the HANS Pro Ultra Lite to our manufacturing roster for Simpson. Rock West delivers lightweight yet strong products that continue to meet customer expectations.

In recent years, our customer needed to reduce production costs, as well as increase efficiency and throughput. We worked to adapt a solution specific to their needs with their input. Rock West relocated HANS production to our plant in Mexico, a facility focused on containing costs for production jobs with high touch labor. With an easy to access plant, Simpson was able to monitor the transition. Our team facilitated training and ensured all quality standards are being met. Our Mexico facility is AS9100D certified with a motivated and quality driven team.

HANS Work in Process

This new production modality has been in place for two years and been an ongoing success. With annual orders for over 1,000 units and with a recent order for more tooling expected to last 5+ years, RWC will continue to make these life saving devices for the foreseeable future.

Our Sporting division is executing development and production work for many customers and hope that we can bring our skills to your company to improve product quality and production efficiency. Contact us!

Sometimes it’s not just our customers who get creative with our products. Our team members like to get in on the action also.

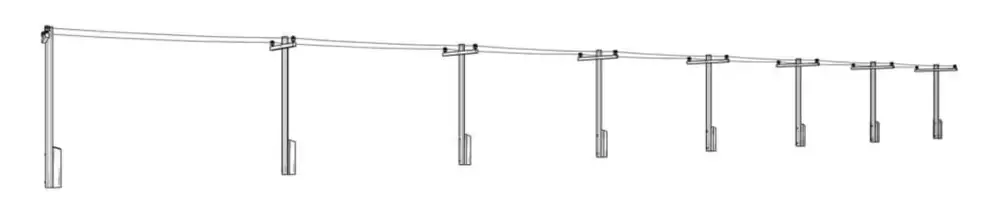

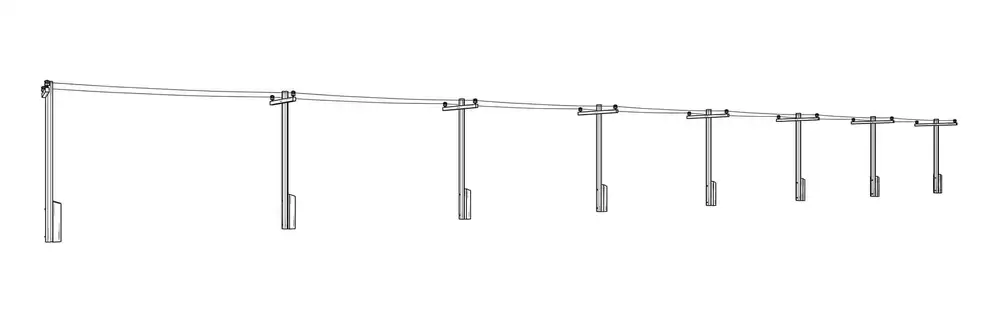

One of our engineers, Brian, was spending hours weeding and picking his strawberry patch. As agricultural labor will tend to do, the gardening was hurting his back and knees. So he decided to make like Tom Cruise in Mission Impossible and dangle over the problematic berry patch!

The Problematic Strawberry Patch

Using a set of carbon fiber tubes and other hardware, he created a lightweight overhead gantry system to suspend himself over the patch. It worked! BUT it was still very painful in a different way and also very complicated. Brian is working on a solution that includes ergonomics in the equation. But in the mean time, take a look at this engineer overachieve at berry picking!

Brian Berry Picking, Mission Impossible Style

We are constantly thinking about the types of projects on which our customers might be working and also about what sort of products they might need to achieve their finished handiwork. So we have just added to our store two products you might find useful in your projects!

Forged Carbon Fiber Blocks

These forged blocks are made with very small chopped carbon fibers and resin and then put at immense pressure as the resin sets. The result is a very strong block of material with isotropic properties.

We offer a variety of thicknesses, and these blocks are fully machinable. They can also be hand shaped using abrasive Dremel tools and sandpaper. Rock West offers machining services for customers who need assistance.

Key Points:

- The blocks have isotropic strength

- They are fully machinable and can be shaped

- Thicknesses range from 0.05″ to 3″

Learn More About CF Blocks!

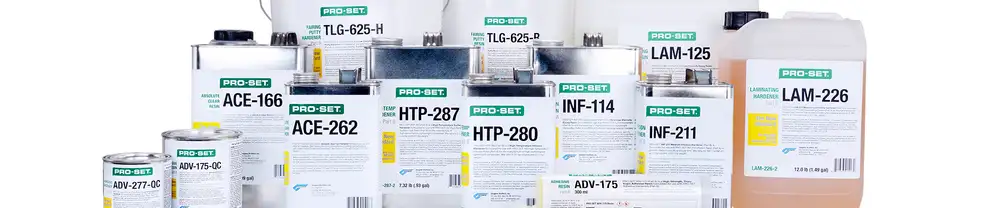

DIY Resin Infusion Kits

We have put together five different sized kits for infusing your own carbon fiber parts. All kits include tubing, COMPOFLEX flow media, vacuum bag material, sealant, and resin infusion hubs. Carbon fiber fabric comes with the three larger kits. Resin and hardener is included in the two largest kits.

These kits are great for the DIY enthusiast who is carbon fiber curious or a seasoned carbon fiber hobbyist who already has some necessary supplies on hand. This can also be a great buy for educational institutions.

Key Points:

- There are five levels of kits to fit your project needs

- You can save money with the kit, which is less than the price of buying all the individual components

Learn More About Our Resin Infusion Kits!

Our forged carbon fiber blocks are currently in stock, and our resin infusion kits are put together when you order. Order today and dive into a new project this summer! We’d love to see what you create, so send our customer service team an email with a picture and description of your project at customer.service@rockwestcomposites.com. Have a great creative summer!

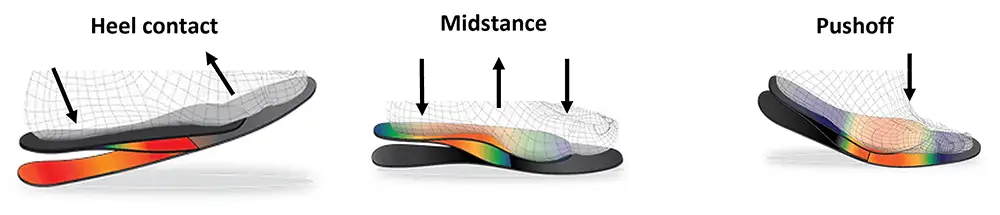

Our new Sporting Division is branching into new industries including innovative composite orthotic inserts used to improve walking biomechanics. Optimizing biomechanics to reduce pain during exercise and maximize sports performance is nothing new, but composites have become increasingly favored to facilitate these improvements.

SubioMed, Inc, a Minnesota medical device startup, has patented and designed various multilayer “suspension biomechanics” products to reduce pain, speed recovery and support health benefits through controlled motion and energy return. They chose composites to optimize flex characteristics, reduce weight, and enhance energy capture and return of their flagship product DSO (Dynamic Suspension Orthotics). Creating independent living hinges to move Ground Reaction Force through the hindfoot, midfoot and forefoot during the “three rockers” of gait was the focus of the design and construction.

RWC worked with SubioMed several years ago on some initial product development. SubioMed reengaged RWC to utilize our experience in design and manufacturing to further enhance their product design and capability. They wanted to reduce costs while increasing efficiency and volume throughput. Our ability to provide composite engineering assistance during multiple phases of manufacturing and competitive production rates with our Mexico facility were instrumental in gaining the production side of the contract.

Our development program was completed in January, and the production program has already initiated. We’ve had great collaboration on design, tooling and flow details between the customer and the RWC team. Brian Bowen SubioMed VP Marketing and Sales shared:

“The SubioMed team has been working on successfully integrating a dynamic suspension into footwear for the last few years. While the patents allow us to develop this revolutionary technology, solving the technical challenges to allow function and durability during millions of cycles of walking required composite expertise. Most recently, the diverse talents of Rock West’s responsive team delivered what we needed prior to execute our initial US launch. The results, data, and patient responses confirm we got it right.”

We are excited to join SubioMed in their mission to restore function and reduce pain to patients who need their technology!

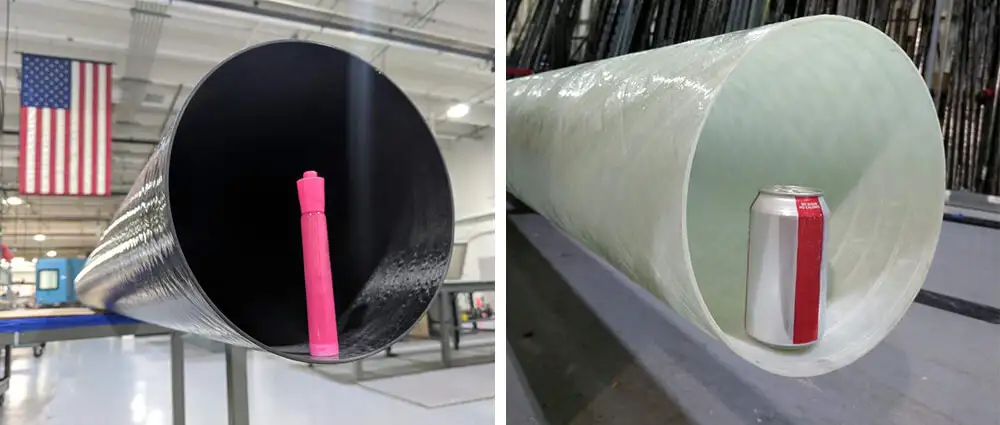

We carry one of the widest selection of tubes available anywhere, with options of varying sizes, materials, properties, and shapes. Even with this incredible variety, we know our selection of off-the-shelf tubing is more limited for large diameter tubes. So we offer a service to cover this spectrum of products – you can Build Your Own Tube!

We have an online tube builder for larger diameter options. You may have seen this before on our website, but we have made some recent improvements. This calculator allows you to order filament wound tubes to your specifications for sizes ranging from 0.999” to 21.532” in diameter and up to 29 feet long. We have 42 mandrels to choose from and in the future, we may add more!

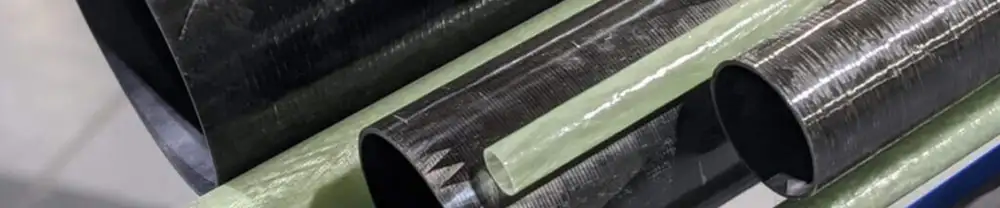

Large diameter custom composite tubes

Do you have specific structural requirements? You can choose a winding and lay up technique that optimizes your tube for lateral strength, torque, or internal pressure.

Do you have temperature-related operational needs? These tubes can be created for either standard temperature ranges (223°F max) or for high temperature resistance (up to 400°F).

What material will support your end-use application? Our tubes can be wound with fiberglass or intermediate carbon fiber; it’s your choice!

What’s new? Because the tubes are wound on a full mandrel and then cut to the length desired, we can maximize material efficiencies, creating cost savings that we pass on to you. Given a desired length, the tool will calculate the optimal number of tubes to create the best price per tube.

Even better, the finished parts take about 2 weeks to complete and ship. So if you want a larger tube and can’t find the specifications you want, build it!

If you are on the hunt for metals, you wouldn’t necessarily expect composites to play a role in the search. But that is precisely what is happening with a customer of ours.

Thousands of people around the word use metal detectors for gold prospecting (or other metals) as their primary occupation. When a metal detector is the tool one uses to provide for their family, a high quality tool can be worth its weight in gold. And when that tool is something you carry all day, a lighter tool is essential. This is where we come in.

Our customer makes metal detectors and needs custom, collapsible, telescoping tubes to comprise the central shaft of the detector. The industry standard material for these shafts is aluminum. The customers wanted a unique product that was more ergonomic. Carbon fiber lightened the load and allowed for organic curves. The tubes are a custom shape that provide smooth nesting for its collapsed state, tight clocking for stability when at full extension, exceptional performance for extreme field conditions, and a lighter swing weight.

These parts also need to have a beautiful finish since they are used for a premium quality product line with a high price point. Using modified closed mold techniques, we are able to provide high gloss surfaces that highlight the beautify of the carbon fiber material. In order to maintain the surface quality, a wipe-on ceramic coating is used to protect the finish.

Carbon fiber in the shop and in the field

Our customer chose us because of our developmental approach to the work and our ability to handle the type of production required for this kind of finished piece. High-speed production lines cannot match the level of surface quality the customer needs. With greater than 250 sets per month and over 3000 units per year, this type of production job is in our sweet spot for exceptional quality and reliable delivery.

We are always excited to tackle a new challenge but it’s even more gratifying when you know you are helping individual people around the world put food on the table.

FOR IMMEDIATE RELEASE

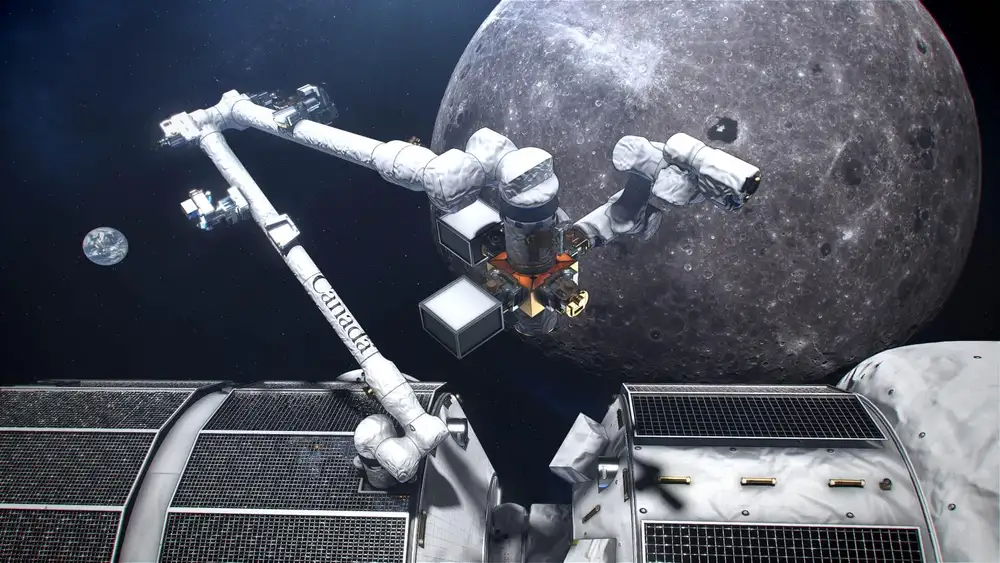

Rock West Composites Completes Development Model Design for Canadarm3

Rock West Composites announces that it has completed the design for the development model for Canadarm3 this month as part of its contract with MDA, a Canadian space company. Over the course of the contract, two primary booms and one qualification boom will be built and tested to support the Canadarm3 robotic arm, which will be supplied by the Canadian Space Agency as part of the lunar Gateway Program.

San Diego, CA (PRWEB) May 1, 2023 – This month Rock West Composites (RWC) has completed the design of the development model for Canadarm3. RWC is collaborating with MDA, a leader in advanced technology solutions for the space industry. The team will design, analyze, manufacture, and test the two primary boom structures and supporting spare units for Canadarm3, Canada’s next-generation robotic arm for the lunar Gateway Program.

According to the Canadian Space Agency, “Canadarm3 will be Canada’s contribution to the US-led Gateway, a lunar outpost that will enable sustainable human exploration of the Moon. This highly autonomous robotic system will use cutting-edge software to perform tasks around the Moon without human intervention.” MDA is tasked with establishing the technical requirements for the program, and RWC is developing the boom structures with MDA.

As a critical component of the Canadarm3 system, the boom structure will be responsible for supporting the robotic arm’s operations and ensuring its stability and reliability over its 20+ year service life. The structure must meet challenging structural and weight requirements, as well as tight dimensional tolerances, operate within wide temperature ranges, and withstand radiation.

“Our collaboration with MDA builds upon our proven track record of delivering innovative solutions for the space industry,” said Jeremy Senne, the head of RWC’s Space market segment. “We are excited to contribute our expertise to this project, work alongside MDA to advance Canada’s space robotics capabilities, and support future deep space presence and exploration by mankind.”

Canadarm is an Official Mark of His Majesty the King in Right of Canada as represented by the Ministry of Industry.

An artist’s concept of Canadarm3, Canada’s smart robotic system, located on the exterior of the Gateway, a small space station in orbit around the Moon. (Credits: Canadian Space Agency, NASA)

For more information on Rock West Composites’ capabilities, visit www.rockwestcomposites.com.

For more information on MDA’s Canadarm3 program, visit https://mda.space/en/canadarm3/.

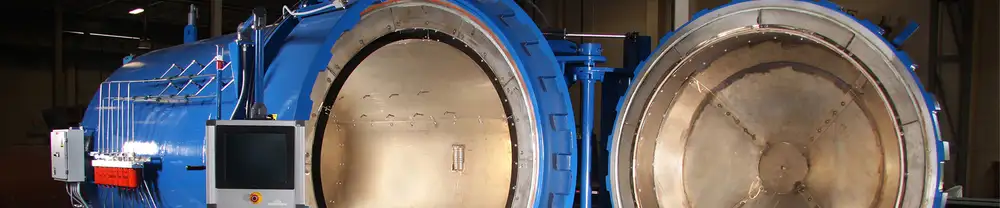

About Rock West Composites

Rock West Composites provides composite products for a variety of markets and customers. Specializing in carbon fiber composites, RWC offers custom products and solutions, such as product development, engineering services, prototyping, and manufacturing, as well as off-the-shelf products, including tubes, plates, complementary materials, and their space-ready STRATO line. Manufacturing processes include filament winding, roll wrap, resin infusion, bladder molding, modified closed mold, compression molding, autoclave cure, and precision assembly. Rock West Composites has facilities in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

Our new Sporting Division is branching into new industries, in particular athletic shoe composite orthotic inserts. Optimizing biomechanics to maximize sports performance is nothing new, but composites has become increasingly favored to facilitate these improvements.

This customer designs biomechanical products to reduce pain, speed recovery and support health benefits though controlled motion. They wanted to use composites to enhance this product’s response while reducing the product’s weight. The hindfoot, midfoot and forefoot were the focus of the design and construction.

RWC worked with this customer several years ago on some initial product development. That customer has reengaged RWC to utilize our experience in design and manufacturing to further enhance their product design and capability. They wanted to reduce costs while increasing efficiency and volume throughput. Our ability to provide competitive production rates with our Mexico facility was instrumental in gaining the production side of the contract.

Initial design tests from earlier product development

Our development program was completed in January, and the production program is completing this month. We’ve had great collaboration on design, tooling and flow details between the customer and the RWC team.

We will be excited to join the customer in their formal product launch in the near future!

FOR IMMEDIATE RELEASE

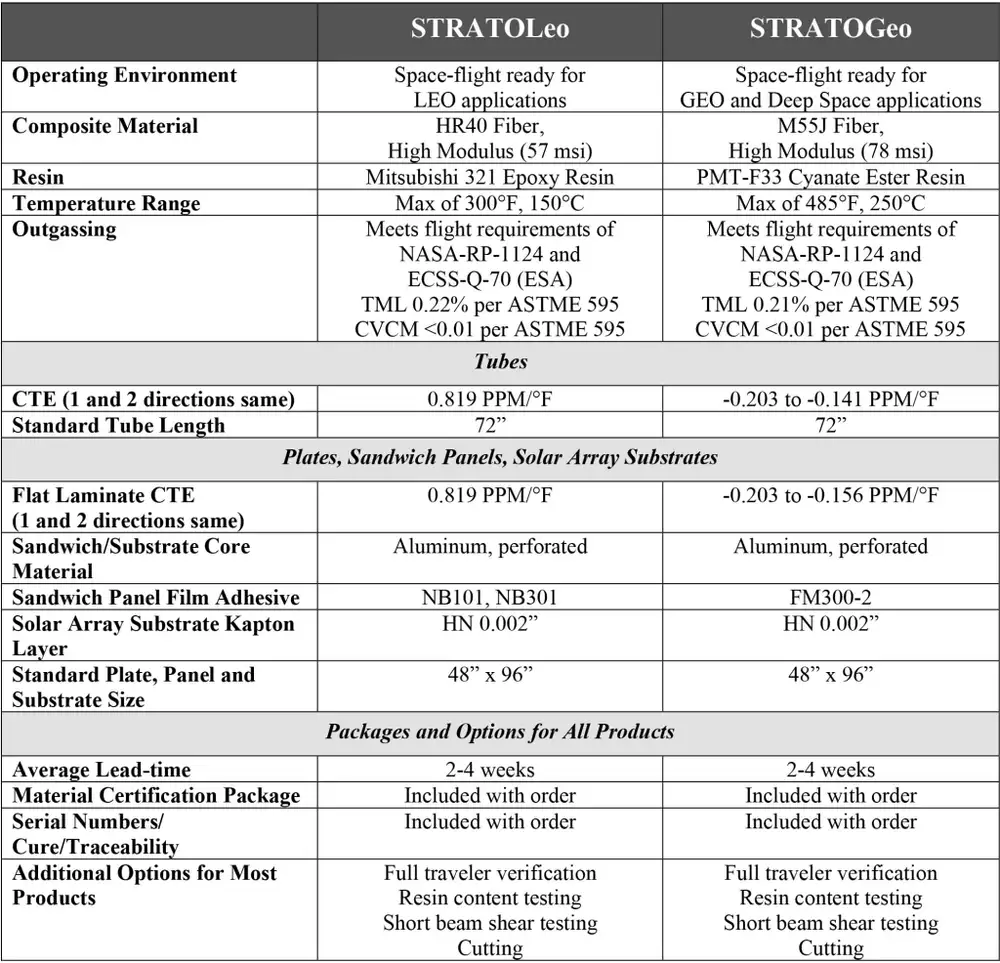

Rock West Composites Is Expanding Its Short Lead Time, Space-Ready STRATO™ Product Line

This month Rock West Composites announces the expansion of its space-grade STRATO product line, which now has two classes created for LEO, GEO and Deep Space applications. These selections of tubes, plates, sandwich panels, and solar array substrates are some of the Space market’s fastest turnaround products with most lead times ranging from two to four weeks.

San Diego, CA (PRWEB) April 11, 2023 – Rock West Composites (RWC) announces the expansion of its STRATO space-grade product line this month. Originally focused on tubes for Lower Earth Orbit (LEO) applications, a secondary line will now include products appropriate for Geosynchronous Equatorial Orbit (GEO) and Deep Space use. STRATO products now include plates, sandwich panels, and solar array substrates for both orbital types.

The STRATO line is designed to provide businesses and government agencies high-quality components commonly needed for spacecraft, but RWC offers dramatically shorter lead times—approximately two to four weeks—than competing providers, and the order can be placed easily online.

The entire STRATO line meets key requirements for space, with properties that include low outgassing, low to zero CTE, high modulus materials, and a wide operational temperature range. RWC can offer significantly reduced lead times because it stocks raw materials such as M55J/PMT-F33 Cyanate Ester and HR40/NB321 Epoxy for its ecommerce business.

The STRATOLeo class is a more cost competitive option for meeting space requirements without the additional high-performance capability typically associated with GEO orbits and Deep Space flights. The STRATOGeo class uses top-of-the-line materials in all cases where performance can’t be compromised. The table below details some of the differences of the product classes.

Each order includes a certificate package with dimensional inspection, material certificates, traceability, and a certificate of conformance from RWC. All products are serialized and traceable. Additional options for some products include full traveler verification, resin content testing, and short beam shear testing.

“Our goal is to make space quality hardware readily available in a cost effective and efficient manner,” said Jeremy Senne, head of RWC’s Space market segment. “Whether it’s a start-up business building cube sats or large prime contractors looking to optimize operations, agile organizations in a rapidly growing industry need high quality solutions quickly. Our hope is to help minimize design and build timelines by standardizing available products.”

For more information on RWC’s STRATO line, visit www.rockwestcomposites.com/strato.

About Rock West Composites

Rock West Composites provides composite products for a variety of markets and customers. Specializing in carbon fiber composites, RWC offers custom products and solutions, such as product development, engineering services, prototyping, and manufacturing, as well as off-the-shelf products, including tubes, plates, complementary materials, and their space-ready STRATO line. Manufacturing processes include filament winding, roll wrap, resin infusion, bladder molding, modified closed mold, compression molding, autoclave cure, and precision assembly processes. Rock West Composites has facilities in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Director of Marketing Communications

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

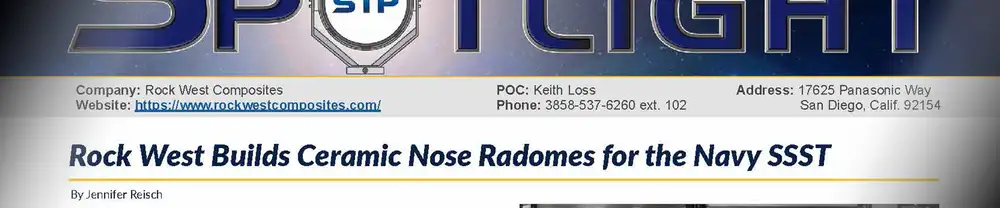

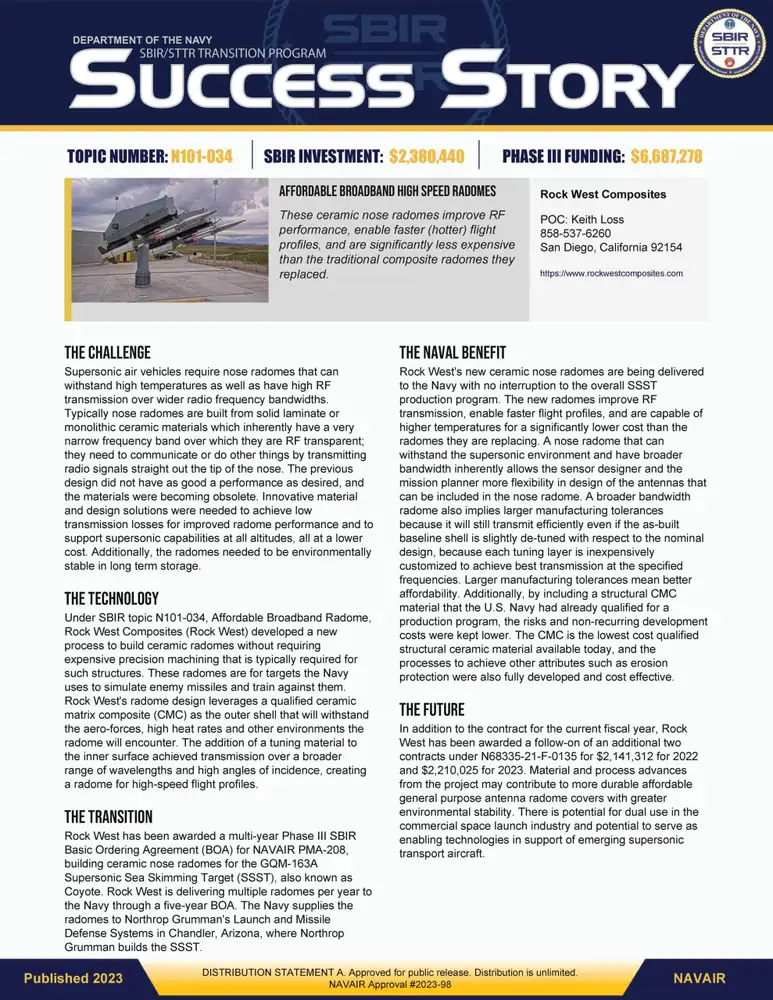

We are proud to support the US Navy through this SBIR program making affordable broadband high-speed radomes. While we’ve talked about this radome program before and even written a case study about it, we’re excited to have been highlighted as a success story by the Department of the Navy’s SBIR/STTR Transition Program office.

We have a total order for 160 radomes to be delivered over four years and are delivering on schedule or earlier.

“The new radomes improve RF transmission, enable faster flight profiles, and are capable of higher temperatures for a significantly lower cost than the radomes they are replacing. A nose radome that can withstand the supersonic environment and have broader bandwidth inherently allows the sensor designer and the mission planner more flexibility in design of the antennas that can be included in the nose radome.”

Read more in the Success Story document below:

Rock West’s best and most important asset is its team of employee-owners. We know that our talented and engaged people are the primary reason why we are able to provide world-class products and services to our customers. We value our team and understand that keeping a healthy environment for everyone matters.

In line with this priority, we are pleased to announce that Cigna has selected Rock West Composites as a recipient of their Silver-level Healthy Workforce Designation for demonstrating a strong commitment to improving the health and well-being of its employees through a workplace wellness program. Rock West’s program focuses on the wellbeing of the whole person, it has leadership buy-in, and it has financial commitment from the company. For example, we engage in activities and challenges around fitness, financial wellness, healthy eating, mindfulness, and career growth, just to name a few.

“We are honored to be recognized with the Cigna Healthy Workforce Designation” said Grace Hernandez, Director of Human Resources. “We understand the important role employee well-being plays in a company’s success and the relationship between healthy employees contributing to a more productive, satisfied workforce and positive business performance.”

As an employee-owned business, the entire team benefits from the enterprise’s success. Investing in an effective workplace well-being program drives value for employee-owners. Senior executives surveyed as part of an Economist Impact study commissioned by Cigna reported greater productivity, stronger staff morale and motivation, and greater retention and loyalty as the most significant business outcomes of a healthy workforce. Additionally, a Gallup Report finds that on average, companies with high employee engagement are 23 percent more profitable.

The Cigna Healthy Workforce Designation evaluates organizations based on the core components of their well-being program, including leadership and culture, program foundations, program execution, and whole person health. Organizations recognized with this designation set the standard of excellence for whole-organization health.

Rock West is proud to offer a healthy and engaging workspace for its people. Join our team if you want to be a part of this terrific group of people!

Reflecting on the Past and Planning for the Future

As we move into our 16th year of business, we are filled with optimism for the future. A business that started as two friends working in a garage has grown to a team of over 200 people in four locations. This growth has been driven by our culture centered around continuous improvement. We always assess past performance to inform how we plan for the future of our business in the world of composites.

People

Our people are our most important asset, which is why we always seek to improve our workplace culture and benefits for Rock West employee-owners. It seems to be working because our San Diego and Salt Lake City locations were named to the 2022 Top Work Places by our local newspapers for the second year in a row! Last year we began building an employee wellness center, which should be completed this year, and our benefits have been expanded based on feedback from our annual survey of benefit preferences. If you want to be a part of a motivated, engaged, and fun group of people, join our team!

Business Markets

Last year we grew revenue over 60%! We made inroads in new markets and reorganized our business development and program management teams around these markets, improving focus on niche requirements and engineering needs as we move forward. You can read more about our Market focus on our recently updated website.

Facilities & Capabilities

We continue to grow and expand our capabilities. Last year we added an additional 5-axis machine to support the manufacture of larger substrates for space hardware, and we built a custom thermal chamber 50-feet long for thermal cycling long narrow substrates. Also, we added new precision assembly tables, a filament winder, a laser tracker for quality assurance, a laser ply placement system and new software for our CNC ply cutting. This year we’ll be adding a large platen press for oversize plate cures, another 6-spindle filament winder, more precision inspection equipment, and another CNC 3-axis router. We’ll also be expanding our Mexico operations. Our plans are adaptable based on the needs of our customers as we move into 2023.

Laser Ply Placement

Infrastructure

When a company grows this rapidly, its infrastructure has to be updated to keep up with the organization’s needs. This year was an optimal time to upgrade many information systems we use to run our business. We are already noticing the gains of changing to more powerful platforms and anticipate the efficiencies becoming more pronounced as 2023 continues. Saving time and keeping smooth operations helps keep our overhead rates competitive and ensures we continue to provide great value to our customers.

Moving Forward…

We hope your 2022 was wonderful and wish you the happiest of years in 2023! We look forward to working with you!!

Like all of you, our colleagues and customers, we are looking forward to taking time off to celebrate and spend time with our friends and families this holiday season. At Rock West Composites, we take this time to rest and recharge seriously, and as we do every year, we will be closing for a week during the holidays.

Plan Ahead and Order Now!

Do you have projects that need composite supplies during the holidays or at the beginning of the new year? You will be able to order online at any time, but fulfillment will be delayed from when we are closed to when we catch up on back orders in January 2023.

Order now! We will work hard to get your product out the door before the break so you have it when you need it. Due to our holiday closure and a planned system upgrade, there may be additional delays on orders placed after December 22nd.

The Details

Our online store will be open for business 24/7, like always. Our offices will be closed from December 24, 2022 to January 2, 2023. Customer Service will be back at the phones Tuesday, January 3, but order fulfillment will resume later in January.

We take pride in being timely with our shipments, and we appreciate your patience as we start the new year taking care of all your composite needs and also spending some time making our systems work better for you.

The team at Rock West wishes you a safe and happy holiday season!

We are proud to sponsor a new composites forum, the Composites Community. It’s a place to find people interested in composites and talk with experts in the field. You can ask our team and other members of our community about products, technical questions and almost anything related to composites.

It’s easy to register! Go to the Composites Community website and click on the Sign Up button in top right corner. You just need your display name, email and password. Then fill out your profile.

We’ve got videos and experts to answer tough questions. For example, community user Mark had a bike repair he was working on and needed some process information. John Kimball, one of our technical experts helped him evaluate the damage and then let him know what process to follow depending on the amount of delamination that occurred.

Our community is new and will be growing fast. We want to invite you to the neighborhood so you can be a part of that growth and interact with people who love composites as much as you do!

We are proud to announce that both our Salt Lake City and San Diego offices have been named Top Workplaces for the second year in a row. The list is based solely on employee feedback gathered through a third-party survey administered by employee engagement technology partner Energage LLC. The anonymous survey uniquely measures 15 culture drivers that are critical to the success of any organization, including alignment, execution, and connection, just to name a few.

Our San Diego headquarters was named by the San Diego Union Tribune as a Top Workplace, joining a limited 115 local companies with the honor. We placed #49 in the small business category.

Our Salt Lake City office was named by the Salt Lake Tribune as a Top Workplace, joining only 155 companies in the region on the list. We ranked #53 in the small business category.

We take employee satisfaction seriously at Rock West. We conduct quarterly surveys about work satisfaction and annual surveys about benefits. We translate this feedback into concrete action. For example, we’ve incorporated popular employee requests, including switching from a 40-hr work week to a 9/80 work schedule. As an ESOP company, all employees are owners. Being personally invested in the company makes for a highly engaged team. Rock West is rapidly growing, and we are hiring. If you are looking to join an amazing team of employee-owners, apply today!

This week Rock West was happy to host 15 engineering students who are currently taking a composites design class at USCD. We provided a short overview on the manufacturing processes that Rock West performs and then gave a tour of the factory floor. This included taking the students from the freezer, to the kitting room, layup and assembly, curing, machining, paint, and quality inspection.

Afterward we provided some pizza allowing for some informal Q&A time. RWC engineers noted that it was great to interact with the next generation of engineers who asked all sorts of great questions!

FOR IMMEDIATE RELEASE

Rock West Composites Introduces New Marine Division Before DEMA Show 2021

Rock West Composites announces the launch of its new Marine Division a week in advance of its attendance at DEMA Show 2021 in booth #1424. Initially focusing on supplying original equipment manufacturers with composite components, Rock West will display new custom products, in addition to off-the-shelf products and materials, relevant to the marine market.

San Diego, CA (PRWEB) November 9, 2021 – Rock West Composites (RWC) announces the launch of its new Marine Division in advance of its attendance at DEMA Show 2021, a premier trade-only event for businesses in the ocean diving and watersports markets. RWC will be in booth #1424. Targeting original equipment manufacturers (OEMs), RWC believes that its unique experience with high-performance industries and commercial markets will enable it to provide high quality products that are both cost effective and schedule sensitive, key issues that are challenging to OEMs.

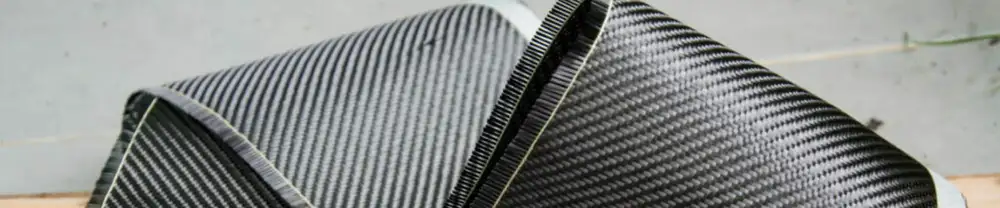

RWC will be focusing on applications including carbon, glass, and hybrid composite free dive fin blades, wrapped and filament wound pole spear tubing, speargun chassis, gaffs, harpoons, technical diving backplates, and mechanical component substructures.

At DEMA Show 2021, the company will highlight a new product, a composites fin blade, which will be on display in the New Product Showcase. The materials are 100% carbon fiber, woven, uni-directional prepreg epoxy. The laminate is quasi-isotropic, strategically stepped and balanced. It has a medium- and soft-flex version available. Blade dimensions are 752mm X 210mm, and it weighs 235 grams. The attachment tendon is a 22-degree angle designed to fit most popular foot pockets. RWC fin blades are designed for high-performance continuous use conditions and are made using the highest quality carbon fiber, fiberglass, and epoxy resin systems and processes.

“We are excited about what we can contribute to this dynamic market space,” said Eric Thorstenson, General Manager of RWC’s Marine Division. “In the diving industry in particular, there is tremendous opportunity for cost efficiencies while retaining the high-quality structures and schedule adherence that original equipment manufacturers demand.”

For more information on Rock West Composites’ capabilities, visit https://www.rockwestcomposites.com/engineering/marine-products.

About Rock West Composites

Rock West Composites provides composite products for a variety of markets and customers. Specializing in carbon fiber composites, RWC offers custom products and solutions, such as product development, engineering services, prototyping, testing, and manufacturing, as well as off-the-shelf products, including tubes, plates and complementary materials. Manufacturing processes include filament winding, roll wrap, resin infusion, bladder molding, modified closed mold, and compression molding processes. Rock West Composites has facilities in San Diego, California; Salt Lake City, Utah; and Baja California, Mexico. www.rockwestcomposites.com

#######

For more information:

Julia Willis, Marketing Director

Phone: 858-537-6260

Email: marketing@1rockwest.com

Website: www.rockwestcomposites.com

It was only a couple of years ago that SpaceX founder Elon Musk unveiled an all-carbon-fiber rocket body for his interstellar spaceship to Mars. Then, seemingly without warning, Musk pulled the plug on the project. He scrapped the carbon-fiber rocket body, closed the Port of LA fabricating facility, and walked away from a lease on land he intended for a full-scale production facility.

Those who follow Musk and his SpaceX exploits were shocked. They had heard for years that carbon fiber was the key to making Mars colonization possible. Learning that he was scrapping carbon fiber in favor of stainless steel was puzzling, to say the least. Well, now we know what happened. We finally know why SpaceX abandoned carbon fiber.

We Now Know Why SpaceX Abandoned Carbon Fiber

A Massive Transport Project

Carbon fiber was the material of choice when SpaceX first began designing its Starship (formerly BFR) rockets. The reason was simple enough: carbon fiber’s impressive strength-to-weight ratio makes it superior to steel and aluminum for massive spaceships carrying unimaginable volumes of cargo.

Understand that a single trip to Mars will take years. The first waves of colonists will not be able to rely on regular supply deliveries similar to that which the International Space Station receives. They will have to take everything they need with them. Practically speaking, you are talking massive ships carrying everything from food to medical supplies and construction materials.

Musk determined that stainless steel would be impractical for building such large ships. Carbon fiber gave him a license to think as big as he wanted. But after a few years of research, building, and testing, he finally reached the conclusion that carbon fiber was not the way to go after all.

Two Big Concerns

Carbon fiber proved to be everything SpaceX thought it would be. However, there were too big concerns. The first is temperature resistance. While carbon fiber stands up extremely well to temperature extremes here on planet Earth, it wouldn’t do so well during atmospheric reentry. It just doesn’t stand up to that much heat.

In order to make carbon fiber work for a reusable rocket, the entire body would have to be insulated. That is certainly possible to do, but it adds to the expense. It also adds to the weight. A stainless-steel rocket body would only have to be insulated on the windward half. The rest of the body would be just fine. Why? Because stainless steel is much more temperature resistant.

The other concern was cost. SpaceX determined that it would spend upwards of $130,000 per ton to use carbon fiber as the primary rocket body material. On the other hand, it would spend just $2,500 per ton for stainless steel. It doesn’t take a mathematician to figure out that spending 50 times as much on carbon fiber would put considerable strain on the Starship project.

A Long Way Off

Musk and SpaceX are now in the process of trying to re-establish production facilities at the Port of LA. Rumor has it they want to begin manufacturing stainless steel rocket bodies and other parts from that location before shipping them across the United States to other facilities. In the end, however, a viable Mars spaceship is still a long way off.

Who knows what SpaceX will learn between now and the day it is ready to launch its first prototype? By then, the cost of carbon fiber materials will likely have dropped significantly. Perhaps improvements in manufacturing technologies will have made carbon fiber as heat-resistant steel. Who knows? SpaceX could eventually scrap stainless steel and go back to carbon fiber again.

If you can build something out of steel, aluminum, or wood, you can probably build it with a composite material as well. Take utility poles. Composite utility poles make up about 1% of the total now deployed around the world. One company in Turkey aims to increase that.

Ankara-based Mitas Group was originally established as a steel company back in 1955. It was formed by the Turkish government to help build the nation’s energy infrastructure. Privatized some 30 years ago, the company produces steel utility poles that are used domestically as well as being exported throughout Europe and to North America, the Middle East, and Africa.

Mitas recently took possession of a filament winding machine that it will use to produce up to 1,000 composite utility poles per month. The automated machine will make Mitas the first such company in Turkey to produce composite poles.

Why utilize composite poles instead of steel and wood? Below are the top five reasons. The rest of the world should pay attention to what Mitas is doing here.

5 Reasons The World Needs To Switch To Composite Utility Poles

1. Composites Don’t Corrode

Composite materials do not corrode like steel. For the purposes of this article, we will assume that Mitas poles will be made of carbon fiber. The poles can be installed with complete confidence that they will not rust. That makes them ideal for coastal areas exposed to salty sea air.

2. Composites Don’t Need Regular Maintenance

Both steel and wood utility poles require regular maintenance. Wood needs more maintenance than steel for obvious reasons. However, a composite utility pole requires no maintenance at all. Once installed, nothing more than routine inspections need be done. A composite utility pole does not need to be re-coated with a protective layer. It does not need to be painted.

3. Composites Are Pest Proof

Wood utility poles are vulnerable to a long list of natural hazards. One such hazard is pest infestation. Everything from termites to wood boring beetles can be problematic for wood utility poles. Replace them with composite poles and the problem is solved.

4. Composites Are Lightweight

Utility poles made of carbon fiber are exponentially lighter than both steel and wood poles. This is important in terms of installation. Imagine attempting to install new poles in a remote, rural location without road access. Getting the poles into position becomes a logistical nightmare. On the other hand, composite poles can be carried by hand and assembled on site.

Because composite poles are so light, they are also easy to install in dense urban environments without the need for heavy cranes and other large equipment. A single pole can be installed in just a couple of hours without major disruptions.

5. Composites Are Strong

Finally, carbon fiber is stronger than both steel and wood. Carbon fiber utility poles will hold up better against everything mother nature can throw at them. For example, they are better able to withstand high winds and the heavy loads such winds generate. Where wood poles might snap, carbon fiber poles will stand tall.

Given that Mitas exports their utility poles around the world, it could be only a matter of time before their products reach our shores. Maybe their success will prompt American manufacturers to secure their own filament winding machines to make composite utility poles domestically.

Image Source: Mitaş Composites

As a leading provider of composite materials in Salt Lake City, we frequently sell products to home fabricators. This includes glass and carbon fiber fabrics, tubes, plates, epoxy resins, and even adhesives. Working with any of these materials does pose some amount of risk to human health. As such, we recommend our home fabricating customers be smart about using personal protective equipment (PPE).

The pros use appropriate PPE whenever working with carbon or glass fiber. We use PPE at all of our facilities. If you are a home fabricator, you should too. Do not take any chances with your health. There is no valid reason to risk injury when a few pieces of PPE will keep you safe. We recommend the following four types of PPE:

4 Pieces Of PPE For Carbon Fiber And Fiberglass Home Fabricating

1. Protective Clothing

At the top of the list is protective clothing that will keep both carbon and glass fibers from contacting the skin. The fibers can be irritating to the skin even among people who don’t normally have reactions to potentially irritating materials. Why? Because both glass and carbon fibers are extremely small. If they get stuck to the skin, they can irritate pretty easily.

Protective clothing should include long pants and a long-sleeved shirt. A hat and work boots are also advised. After working with glass or carbon fiber, your protective clothing should be washed. Do not hang it up dirty and reuse it later as you run the risk of transferring fibers stuck on the clothing onto your skin.

2. Nitrile and Work Gloves

Next, we recommend two different types of gloves. During the fabrication stage, use nitrile gloves to prevent contact with epoxy resin and loose carbon and glass fibers. Nitrile gloves do the job and are very inexpensive. Best of all, they are disposable. That means you do not have to try to clean your gloves after handling epoxy.

Post fabrication, we recommend a pair of heavy-duty work gloves to protect your hands during grinding, cutting, sanding, etc. The purpose here is to protect your hands against any splinters that may result from machining finished parts.

3. Eye Protection

It is absolutely imperative to protect your eyes whenever you are working with composite materials. During the fabrication stage, you don’t want glass or carbon fibers in the air to make contact with your eyes. You do not want epoxy to accidentally splash up into your face either. During machining process, eye protection keeps you safe from carbon fiber dust and splinters. In both cases, safety glasses are the bare minimum.

4. Face Masks

Finally, it is wise to protect your respiratory system by wearing a face mask. A mask reduces the risk of exposure to small carbon fibers and carbon fiber dust. A filtered mask can protect you against the sometimes-overwhelming fumes put off by epoxy resins.

In addition to a mask, it’s advisable that you fabricate with carbon and glass fiber in well ventilated areas. Ventilation allows for faster dispersal of annoying fumes. With good ventilation, you will breathe easier and have a lower risk of being overcome.

One last thing we advise: familiarize yourself with appropriate first aid. For example, it’s best to treat skin irritation and rashes by washing the affected skin with soap and warm water to remove fibers. There is no need to scrub, and you probably shouldn’t if your skin is already irritated.

We applaud your desire to fabricate with glass and carbon fiber at home. Both materials offer a tremendous number of applications for home fabricators. Just do yourself a favor and be safe. Wear the appropriate PPE whenever you are working on composite projects.

Take a close look at a section of carbon fiber or fiber glass tubing or plate and you will see that the fibers go in different, specific directions. Comparing different styles of tubing you might notice that fiber direction, also known as orientation, is not always uniform. Composite tubing and plate manufacturers use different orientations depending on what they want to accomplish with the finished product.